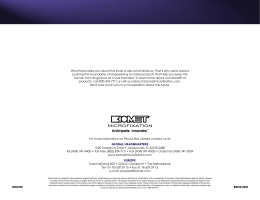

Braz J Oral Sci. October-December 2005 - Vol. 4 - Number 15 Effect of different torque levels on the implant/abutment interface using castable “UCLA” abutments Gustavo Augusto Seabra Barbosa1 Paulo Cézar Simamoto Junior2 Alfredo Júlio Fernandes Neto3 Maria da Glória Chiarello de Mattos4 Flávio Domingues das Neves5 1 DDS, MS, PhD Student, School of Dentistry of Ribeirão Preto, University of Sao Paulo. Substitute Professor at Department of Fixed Prosthodontics, Occlusion and Dental Materials, Federal University of Uberlandia. 2 DDS, MS, PhD Student, Piracicaba Dental School, State University of Campinas 3 DDS, MS, PhD, Titular Professor at Department of Fixed Prosthodontics, Occlusion and Dental Materials, Federal University of Uberlandia 4 DDS, MS, PhD, Professor at Department of Dental Materials and Prosthesis at School of Dentistry of Ribeirão Preto, University of Sao Paulo 5 DDS, MS, PhD, Assistant Professor at Department of Fixed Prosthodontics, Occlusion and Dental Materials, Federal University of Uberlandia Abstract The abutment/implant interface has been reported as a significant factor on tensile transfer, adverse biological responses or prosthetic restoration complications. The abutment/implant junction success is directly related to pre-load attained during torque application. The purpose of this work was to assess the vertical fit/misfit degree on abutment/implant interface, when castable “UCLA” type abutments are used on fixed prosthesis process on implants, after different torque levels applications. Four three-unit fixed prosthesis were manufactured by the same laboratory. Torque was applied on the same framework using initially a 10 Ncm (T1) and later, a 20 Ncm torque level (T2) with a screwdriver hand Torquimeter. Trough scanning electronic microscope (SEM), it was obtained two photographs corresponding to mesial and distal regions of each prosthesis unit, summing 24 assessed regions to each applied torque value. After submitting the results to statistical analyses Paired T-Test (p<0.05), a significant difference was seen between the average vertical fit/misfit degree: T1 = 23.53mm ± 20.20; T2 = 9.01m ± 11.69 (p=0.000). The misfit degree decrease when applied manufacturers recommended torques, could decrease mechanical (loosening or fracture of the screw) complications. Key Words: dental implants, prosthetic adjustment, torque Received for publication: May 24, 2005 Accepted: November 21, 2005 Correspondence to: Gustavo Augusto Seabra Barbosa Av: Brasil , 4800, Bl. C; Apt 102 – Umuarama CEP: 38405-312 – Uberlândia/MG Phone: (34) 3232-7356 E-mail: [email protected] / [email protected] 919 Braz J Oral Sci. 4(15):919-922 Effect of different torque levels on the implant/abutment interface using castable “UCLA” abutments Introduction The abutment/implant interface has been reported as a significant factor on stress transfer, adverse biological response or prosthetic restoration complications1. Michalakis et al.2 reported two likely complications types inherent to a misfit of the prosthetic framework: a) biological – increased load transfer to bone, bone loss, and microflora development in the micro-gap between implant and abutment3-4; and b) prosthetics – loosening or fracture of the screw and implant loss 5. Due to periodontal ligament absence, implants are incapable to readily adapt to misfit restorations induced stresses6. It should than, have a relative precision on fit between prosthesis and abutments, as also between prosthesis and implants7, to the implant-supported restorations long term success 8. However, there’s no perfect fit, and thus, the clinicians should accept certain misfit level, which doesn’t affect the bone/implant interface health9. According to early information about osseointegration, it is considered that an acceptable fit, values less than 10µm10. The screw tightening aim to maintain the union between components. However, during function, micro-gaps could be formed on the abutment/implant interface due to an untight abutment fixture, favoring bacterial invasion, as well as mechanical problems11. On every implant system the fixture joint system efficiency depends on several factors: the component design; connection geometry between implant and abutment; mechanical adjustment between fixture and its set surface on abutment; the mechanical and physical component properties and torque application12. The tension needed to maintain two parts of the same junction tightly united, either under static or dynamic conditions, is referred as preload13. Surface imperfections lead to friction rising and to decreasing of such pre-load. Increasing the same is due to screw take off and consequent tightening 13-14 . During abutment screw tightening, a compressive strength is generated to keep implant and abutment surfaces in touch. This joint success is directly related to attained pre-load during torque and for this preload maintenance with time. The fixture untightening, as also the pre-load reduction to critical levels, can compromise the joint stability, making a clinical failure more powerful15. Regarding to the screw tightening, some authors report that increasing the torque applied on screws, the compression between the facing surfaces is also increased, producing a greater stability on the joint16. In one study comparing the micro-leakage level on abutment/ implant interface of five implant systems, varying the torque between 10 Ncm and 20 Ncm, the authors observed significant differences on micro-leakage between applied torques. There was a significant decrease when the torque was near to recommended values17. 920 Due to a great misfit presented by UCLA abutment, this study aims to evaluate the vertical fit/misfit degree on abutment/ implant interface, when using castable “UCLA” type abutments, with different torque levels. Material and Methods Four three unit fixed prosthesis were manufactured from a metallic matrix with three compatible Brånemark implants (3,75x10mm) (Conexão Sistemas de Prótese, Sao Paulo, SP, Brazil). Those were made of castable UCLA type abutments (Conexão Sistemas de Prótese, Sao Paulo, SP, Brazil), with nickel-chrome alloy (Verabond II, Albadent Inc., USA). The frameworks were united with conventional solder method. They were placed on the matrix, first with 10 Ncm torque (screwdriver hand Torquimeter, Conexão Sistemas de Prótese, Sao Paulo, SP, Brazil) (Treatment 1 – T1) so the first analyze could be done, using the scanning electronic microscopy (SEM, LEO 435 VP, GERMANY), at a x500 magnification. Later, the same frameworks were placed, with a 20 Ncm torque (Treatment 2 – T2), to the last analyze. For each framework “dental unit”, two images were obtained, one mesial and other distal, making a total of 24 images. The images were printed using a laser printer (Laser Jet 1500L, Hewlett Packard, USA). From the printed photos, a ruler was built with the micrometers scale existing on the lower portion of the images, by a rule of three. Tracing a line paralleled to the implant platform and other parallel to lower surface of the abutment the vertical fit/misfit value can be obtained, if it’s present. Looking for a better view of the results, the measurement site received a number (Table 1). Factors as visual accuracy, view angle, light and professional experience, were described by Kan et al.18, as the factors that could interfere on the accurate determination of misfit. To minimize those interference factors, three examiners were trained to the measurements. Statistical processing was done using the SPSS data program (SPSS/ PC for Windows Inc., Chicago, IL). Parametric statistical test were used, with the Paired T- test for paired samples. A pvalue less than 0.05 was considered statistically significant. Results and Discussion The three examiners mean values for vertical misfit after two torque levels apply (T1 and T2) are expressed in µm, on Table 2. As showed on table 2, all misfit values were larger when 10 Ncm load was applied, decreasing, in some cases, more than 35µm after applied torques of 20 Ncm load (as show regions 13 and 19, table 2). After 20 Ncm torque application sixteen analyzed regions presented values less than 10µm and figures 1 and 2 exemplify the best fit obtained with this torque level. The statistical analysis (Paired Ttest) presented significant difference in the vertical fit among the two levels of applied torques (p=0.000), being lower when used 20 Ncm. Braz J Oral Sci. 4(15):919-922 Effect of different torque levels on the implant/abutment interface using castable “UCLA” abutments Table 2. The three examiners average for vertical misfit, in µm. Table 1. Regions of mensuration. LOCAL REGIONS Mesial of right upper premolar Distal of right upper premolar Mesial of first right upper molar Distal of first right upper molar Mesial of second right upper molar Distal of second right upper molar Mesial of left upper premolar Distal of left upper premolar Mesial of first left upper molar Distal of first left upper molar Mesial of second left upper molar Distal of second left upper molar Mesial of right inferior premolar Distal of right inferior premolar Mesial of first right inferior molar Distal of first right inferior molar Mesial of second right infeior molar Distal of second right infeior molar Mesial of left inferior premolar Distal of left inferior premolar Mesial of first left inferior molar Distal of first left inferior molar Mesial of second left inferior molar 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 Distal of second left inferior molar 24 Torque Level Regions T1 10NCm T2 20NCm 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 27.5 55 23.3 5 10 13.3 30 2.5 10 10 9.1 50 65 5 22.5 30 25 5 65 50 2.5 5 35 15 30 8 5 2.5 10 5 0 0 0 5 30 30 0 0 0 0 0 27.5 25 0 0 23.3 24 9.1 0 Fig.1. Vertical misfit after 10 Ncm torque application. Fig. 2. Absence of the misfit in the same abutment, after 20 Ncm torque application In the present study, a misfit until 10µm was concerned as clinically acceptable10, because an absence of perfect fit between abutment and implant9. A relative precision on the fit between prosthesis and abutment, as well as prosthesis and implant7, is important for the long term success of implant-supported restorations1,8. Because of the absence ligament between bone and implants the restorations misfit could induce stresses on the marginal bone6. An abutment-implant interface misfit could produce mechanical and biological problems2-5,11. Factors such as torque application were described like important characteristics for the efficiency of screw junction on implant systems12. The casting process could change the mechanical performance and structural properties of the contacting surfaces during screws tightening, changing either, the frictional resistance value of the applied torque12. 921 Braz J Oral Sci. 4(15):919-922 Effect of different torque levels on the implant/abutment interface using castable “UCLA” abutments It could also compromise the junction stability, increasing to possibility of clinical failure15. In the present study, when the castable UCLA and the casting process were used, the fit degree was significantly modified in relation to torque level. The present study observed a significant difference on fit degree between abutment/implant interface related to the screw applied torque. When applying different torque levels (10 and 20 Ncm), a lower misfit was observed when 20 Ncm was used. In this torque level, sixteen regions presented values clinically acceptable (less than 10µm), while 10 Ncm torque level presented thirteen regions with larger values than 10µm (table 2). Jörnéus et al. 16 observed that when increasing the applied torque level on screws, the compression between the contacting surfaces also increases producing a greater stability on the junction and lower misfit. Screwed junctions with torques exceeding the recommended present lower micromovement, without apparent system commitment 11,14. However, it agrees in part with such affirmative since in the situation of 10 Ncm torque greater misfit were observed. Nonetheless, applying torque greater than recommended can produce an exacerbated stress on screws. Still on the presence of a misfit in which the tow faces (implant platform and abutment base) are not in ideal contact and hence it can’t have contact by load apply. This screw will experience its maximum loading, thus decreasing its life-span19. On a static analyze, with the screw tightening besides the manufacturers recommended levels it can obtaining a more stable junction decreasing the problems with screw loosening14. On another study varying torques between 10 Ncm and 20 Ncm, the authors observed that fluids and small molecules have the capacity of penetrating the abutment/implant interface of all studied systems. However, there are significant differences on micro-leakage between the 10 Ncm and 20 Ncm torques, decreasing significantly when the torque was near to the recommended values17. In the present study, a lower misfit is observed when applying manufacturers recommended torques (20 Ncm), and it could difficult the microorganisms penetration on abutment/implant interface, decreasing the potential of biological risks to restorations. According to the results obtained in this study, the application of appropriate torques can decrease implant/ abutment misfit, and thus could decrease mechanical (loosening or fracture of the screw) complications. Acknowledgments Conexão Sistemas de Prótese LTDA; Professor Elliot Watanabe Kitajima from the ESALQ (Escola Superior de Agricultura “Luiz de Queiroz”). References 1. 922 Jemt T, Rubenstein JE, Carlsson L, Lang BR. Measuring fit at the implant prosthodontic interface. J Prosthet Dent. 1996; 75: 314-25. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. Michalakis KX, Hirayama H, Garefis PD. Cement-retained versus screw-retained implant restorations: a critical review. Int J Oral Maxillofac Implants. 2003; 18: 719-28. Jansen VK, Conrads G, Richter E. Microbial leakage and marginal fit of the implant-abutment interface. Int J Oral Maxillofac Implants. 1997; 12: 527-40. Quirynen M, De Soete M, Van Steenberghe D. Infectious risks for oral implants: a review of the literature. Clin Oral Implants Res. 2002; 13: 1-19. Burguete RL, Johns RB, King T, Patterson EA. Tightening characteristics for screwed joints in osseointegrated dental implants. J Prosthet Dent. 1994; 71: 592-9. Listgarten MA, Lang NP, Schroeder HE, Schroeder A. Periodontal tissues and their counterparts around endosseous implants. Clin Oral Implants Res. 1991; 2: 1-19. Aparicio C. A new method for achieving passive fit of an interim restoration supported by Brånemark implants: a technical note. Int J Oral Maxillofac Implants. 1995; 10: 614-8. Watanabe F, Uno I, Hata Y, Neuendorff G, Kirsch A. Analysis of stress distribution in a screw-retained implant prosthesis. Int J Oral maxillofac Implants. 2000; 15: 209-18. Taylor TD, Agar JR. Twenty years of progress in implant prosthodontics. J Prosthet Dent. 2002; 88: 89-95. Brånemark PI, Zarb GA, Albrektsson T. Introduction in Osseointegration. In: Brånemark PI, Zarb GA, Albrektsson T. Tissue-integrated prostheses. Osseointegration in clinical dentistry. Chicago: Quintessence Books; 1985. Cap.1 Gratton DG, Aquilino AS, Stanford CM. Micromotion and dynamic fatigue properties of the dental implant-abutment interface. J Prosthet Dent. 2001; 85: 47-52. Carotenuto G, Palumbo M, Zarone F, Nicolais L. Characterization of the interface between prefabricated gold copings and cast dental alloy in implant restorations. Clin Oral Implants Res. 1999; 10: 131-8. Tzenakis GK, Nagy WW, Fournelle RA, Dhuru VB. The effect of repeated torque and salivary contamination on the preload of slotted gold implant prosthetic screws. J Prosthet Dent. 2002; 88: 183-91. Haack JE, Sakaguchi RL, Sun T, Coffey JP. Elongation and preload stress in dental implant abutment screws. Int J Oral Maxillofac Implants. 1995; 10: 529-35. Cibirka RM, Nelson SK, Lang BR, Rueggeberg FA. Examination of the implant-abutment interface after fatigue testing. J Prosthet Dent. 2001; 85: 268-75. Jörnéus L, Jemt T, Carlsson L. Loads and designs of screw joints for single crowns supported by osseointegrated implants. Int J Oral Maxillofac Implants. 1992; 7: 353-9. Gross M, Abramovich I, Weiss EI. Microleakage at the abutmentimplant interface of osseointegrated implants: a comparative study. Int J Oral Maxillofac Implants. 1999; 14: 94-100. Kan JY, Rungcharassaeng K, Bohsali K, Goodacre CJ, Lang BR. Clinical methods for evaluating implant framework fit. J Prosthet Dent. 1999; 81: 7-13. Patterson EA, Johns RB. Theoretical analysis of the fatigue life of fixture screws in osseointegrated dental implants. Int J Oral Maxillofac Implants. 1992; 7: 26-34.

Download