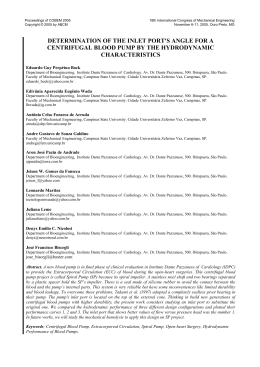

PRODUÇÃO E UTILIZAÇÃO DE GÁS NATURAL: TRÊS PESQUISAS EM DESENVOLVIMENTO NA POLI - USP Silvio de Oliveira Júnior Departamento de Engenharia Mecânica ESCOLA POLITÉCNICA DA USP [email protected] Heat Transfer In A Twin-screw Multiphase Pump: Thermal Modeling And One Application In The Petroleum Industry Celso Yukio Nakashima Silvio de Oliveira Jr. Polytechnic School - University of São Paulo Elisio F. Caetano Petrobras/Cenpes Objectives • Modeling of heat transfer through screws and casing • Analyze thermal behavior during LOP events • Find temperature distributions in screws and casing • Seek for critical temperature values during LOP SMPS-500 Flow: 500 m3/h Dp=60 bar Speed: 0 – 3000 rpm GVF = 0-95 % Twin-Screw Pumps chambers discharge suction casing peripheral clearance radial clearance flank clearance Thermal Modeling • Energy streams Wk Casing Casing Uk Uk-1 Uk+1 Fluid Screws Uk Rotor r Qkr Qkc Qenv Thermal Modeling • Energy and mass balances dmk m ki m ko dt dU k d ( mk u k ) Qk Wk m ke hke mks hks dt dt • During LOP dU k Q k Wk dt dmk 0 dt • Heat Transfer Qk Q kc Q kr Thermal Modeling • Heat transfer through casing y Re r Ri ( - ) max Re r ( Re - R i ) x Ri Re r 2 1 c cc T T T T T T J J 2 J J J kc t r r r z Thermal Modeling • Heat transfer through rotors 2 2 1 T p T r 1 t r r r 2r 2 r cr T kr Thermal Modeling • Heat transfer coefficients Rotor/fluid Casing/fluid Screw tip Screw flank Screw bottom h (W/m2 .K) 3000.0 500.0 55.0 1250.0 Thermal Behavior During LOP • Sample data during LOP 600 90 80 500 FLOW - M3/HR 400 60 50 300 40 200 30 20 100 10 0 15:02:53 0 15:04:19 15:05:46 15:07:12 TIME - HR:MIN:SEC FLOW CASING T 15:08:38 15:10:05 15:11:31 TEMPERATURE - °C 70 Thermal Behavior During LOP • Results (a) Screw temperature before LOP (b) Screw temperature after LOP (c) Casing temperature after LOP Conclusions • Temperature rise was not critical; • Prime recovery reduces temperatures; • Next steps: – Calculation of heat transfer coefficients – Coupling of heat transfer model with the thermo-hydraulic model of a twin-screw multiphase pump PERFORMANCE OPTIMIZATION OF NATURAL GAS AND SUGARCANE BAGASSE BASED COGENERATION SYSTEM Leonardo Moneci Zamboni; Silvio de Oliveira Jr. and Arlindo Tribess Mechanical Engineering Department Polytechnic School of the University of São Paulo - BRAZIL Objective This paper presents the exergy and thermoeconomic performance evaluation of cogeneration systems designed for a sugar and alcohol mill that uses natural gas and sugarcane bagasse as fuels. Cogeneration systems The combined use of natural gas and sugarcane bagasse in cogeneration plants can generate electricity and steam for processes as well as to allow the commercialization of surpluses. Cogeneration Systems natural gas 2 3 8 System A combus tion chamber 4 2 gas turbine compressor air 7 9 1 heat recovery steam generator 10 1 generation 1 5 cogeneration steam 8 12 18 10 H node generation 2 steam turbine 20 13 19 19 process 23 11 stack lost steam 17 14 condens er 12 pump 23 27 17 node 14 16 13 15 20 pump 21 5 replacement water 6 Cogeneration Systems natural gas 2 3 8 System B combustion chamber 4 2 gas turbine compressor air 7 9 1 heat recovery steam generator 10 1 generation 1 5 node 8 12 cogeneration steam 18 10 H steam turbine steam generator 9 air 21 16 18 17 generation 2 13 19 11 lost steam H 23 22 cane bagasse 14 4 7 stack 22 condens er 12 20 26 pump 24 23 node 27 17 node 14 16 19 process 13 15 20 pump 21 5 replacement water 6 Cogeneration Systems natural gas 2 System C combustion chamber 3 8 4 2 gas turbine compressor air 7 9 1 heat recovery steam generator 10 1 generation 1 5 node 8 12 H 23 21 11 15 18 F 17 generation 2 13 steam generator 9 16 18 10 steam turbine air preheater air cogeneration steam 19 11 lost steam H 22 25 cane bagasse 14 4 7 condens er 12 20 26 stack 22 24 23 node pump 27 17 node 14 16 19 process 13 15 20 pump 21 5 replacement water 6 Cogeneration Systems natural gas 2 System D combustion chamber 3 8 4 2 gas turbine compressor 1 air generation 1 9 7 cane bagasse 3 5 6 1 node cogeneration steam 10 8 heat recovery steam generator 12 18 10 H generation 2 steam turbine 13 19 11 17 lost steam 20 23 stack 14 condens er 12 pump 23 27 17 node 14 16 19 process 13 15 20 pump 21 5 replacement water 6 Cogeneration Systems natural gas 2 3 8 System E combustion chamber 4 2 gas turbine compressor air 7 9 1 heat recovery steam generator 10 1 generation 1 5 node 8 12 cogeneration steam 18 10 H dryer steam turbine steam generator 6 3 9 16 17 11 23 cane bagasse 18 generation 2 13 11 22 14 4 7 26 22 condens er 12 air 20 pump 24 23 node 27 17 node 14 16 19 lost steam H 15 stack 19 process 13 15 20 pump 21 5 replacement water 6 Cogeneration Systems natural gas 2 System F combustion chamber 3 8 4 2 gas turbine compressor air generation 1 9 7 1 5 1 heat recovery steam generator 10 cogeneration steam 8 12 18 10 H steam turbine 6 dryer generation 2 13 19 23 11 20 17 lost steam 7 3 stack 16 14 11 19 process cane bagasse condens er 12 pump 23 27 17 node 14 16 13 15 20 pump 21 5 replacement water 6 Cogeneration Systems natural gas 2 3 8 System G combustion chamber 4 2 gas turbine compressor air 7 9 1 heat recovery steam generator 10 1 generation 1 5 node 8 12 cogeneration steam 18 10 H steam turbine steam generator 9 air 21 16 18 17 generation 2 13 19 11 lost steam H 23 22 cane bagasse 14 4 7 stack 22 pump 24 23 node 27 17 During 6 months condens er 12 20 26 node 14 16 19 process 13 15 20 pump 21 5 replacement water 6 Results Specific average cost of eletricity [US$/MWh] 44 Sistema A Sistema B Sistema C Sistema D Sistema E Sistema F Sistema G 42 40 38 G B E 36 C 34 F 32 30 6 A D 8 10 12 14 16 18 20 22 24 26 28 Sugar cane bagasse price [US$/t] SISTEMA TETRA-COMBINADO DE TRIGERAÇÃO AVALIAÇÃO TERMOECONÔMICA Domingo Wilson Garagatti Arriola Silvio de Oliveira Júnior ESCOLA POLITÉCNICA DA USP Sistema Tetra-Combinado de trigeração, para produção de eletricidade, água gelada e vapor de processo Parâmetros de desempenho do sistema Tetra-Combinado de Trigeração Ept (kW) 15853 Qev (kW) 3872 Qp (kW) 4941 b ( %) 0,556 45,00 e ( %) 68,00 Custos de produção das utilidades geradas ce (US$/MWh) cv (US$/t) cag (US$/t) 36,37 19,23 0,13

Baixar