Knowledge Management strategies on service production. A System Dynamics approach Mauricio Uriona Maldonado Eng. Post-Graduate Program in Knowledge Engineering and Management (EGC) Fellow of the Programa Estudiante Convenio de Pós-graduaçao PEC-PG/CNPQ Universidade Federal de Santa Catarina, Brazil (UFSC) [email protected] Renata Jorge Vieira Ms.C. Post-Graduate Program in Knowledge Engineering and Management (EGC) Universidade Federal de Santa Catarina, Brazil (UFSC) [email protected] Gregorio Varvakis Ph.D. Post-Graduate Program in Knowledge Engineering and Management (EGC) Universidade Federal de Santa Catarina, Brazil (UFSC) [email protected] Paulo Mauricio Selig Dr. Post-Graduate Program in Knowledge Engineering and Management (EGC) Universidade Federal de Santa Catarina, Brazil (UFSC) [email protected] Abstract The service industry is gaining more space on regional and global markets. The main characteristics that differentiate services and manufacturing industries which are intangibility, simultaneity and non-stockability require Operations Strategy and Knowledge Management Strategies to fit. This paper proposes to identify the non-linear relationships between “Training Programs” strategies and long-term Financial results, through dynamic simulation. The main issues regarding Service Operations Strategies, and Knowledge Management Strategies are introduced, linking training programs with organizational knowledge creation. The selected output indicators are: Income, Expenses, Balance, Explicit and Tacit Knowledge. As a result, a System Dynamics model of a Software-development company’s service production system is constructed, including a KM sub-model, a Workforce sub-model, a Customer Management sub-model, a Financial Management sub-model, afterwards it is tested in three different investment scenarios. The model suggests that investments in personnel training are important for service production systems. The use of System Dynamics methodology, techniques and tools improves decision-making for Operations Management, facilitating the understanding of the system’s behavior and structure, especially the effects of KM strategies on service production systems. Keywords: Knowledge Management, Service Production, System Dynamics, Operations Strategy. 1. Introduction When service industry is discussed, it is common to find literature about the industry’s positioning on world’s economy, evidently, the service industry has been growing in importance in regional economies in the last decades, the main indicators of this grow are GDP and labor occupation percentage. Both indicators have been increasing in developed countries like the USA (CHASE et. al., 2004; FITZSIMMONS & FITZSIMMONS, 1997), as well as in developing countries like Brazil (GIANESI & CORRÊA, 1994). This is because the “service” concept was introduced in traditional manufacturing companies, aiming to increase their core products’ value, and also in companies dedicated to produce services, like the Hotel, Health, Software and Financial industries, generating value through the delivery of intangibles (OLIVA & STERMAN, 2001). According to Chase et. al. (2004) and Slack (2005) the boundaries between service and manufacturing companies are getting more difficult to be identified, since both are becoming more interconnected and integrated. The main differences between service operations and manufacturing operations are intangibility, simultaneity, and non-stockability (GIANESI & CORRÊA, 1994; FITZSIMMONS & FITZSIMMONS, 1997). These differences, and specially the “intangibility” issue, bring new concepts, like the “Knowledge Era”, “Knowledge Worker” (DRUCKER, 1999) and “Knowledge Factories” (ROTH et. al., 1994). This paper sheds some light about the effects produced by Knowledge Management strategies in production service systems, considered to-be complex and non-linear, from a System Dynamics perspective, a methodology that facilitates understanding of complex systems behavior and structure, allowing, via computer-simulation, the introduction of new or different organizational politics and the visualization of the effects produced (STERMAN, 2000). 2. Service Production Systems Organization main goals are basically to “get and keep customers” and to “make a profit” (BERRY, HILL & KLOMPMAKER, 1995). Both goals depend on the Production System, which is responsible for producing goods and services in the organizations, therefore Operations Strategy is vital for gaining competitive advantage and for delivering quality services to customers (CHASE et. al., 2004). For Chase et al. (2004) and Gianesi &Corrêa (1994) Operations Strategy refers to plans and politics formulation, seeking the best use of operative resources, for supporting the Firm’s strategy, by the production of goods and services that satisfies costumers’ needs (SLACK, 2005). Operations Strategy implies decisions related to production processes design and supporting infrastructure for those processes (CHASE et al., 2004), namely: service project, process-technology, facilities, capacity-demand, workforce, quality, customer management, performance measurement, operations control and improvement systems, among others (CHASE et. al., 2004). According to Roth et. al. (1994), the competitiveness comparison basis have changed since new types of non-tangible products are becoming more common, pushing organizations to achieve a state called “customer-readiness”, influenced by new value-added sources like organizational knowledge. Terms like the “knowledge factory” (ROTH et. al., 1994), the “knowledge-creating company” (NONAKA & TAKEUCHI, 1997) and the “knowledge worker” (DRUCKER, 1999; HAMMER et. al., 2004) refer to a new competitive priority in organizations, which is to create organizational knowledge through learning in parallel with service production. This paper suggests that in order to improve competitive advantage, organizations must fit Operations Strategy and Knowledge Management strategies. 3. Knowledge Management strategies in service organizations In recent years, many researchers have argued that the capability to create knowledge is the most important source of competitive advantage (NONAKA & TAKEUCHI, 1997; DRUCKER, 1999). The discipline which studies the theoretical approaches of organizational knowledge creation is Knowledge Management (DALKIR, 2005). There are many definitions of Knowledge Management (KM), for Davenport & Prusak (1998) it is the “collection of process that aims to govern the creation, dissemination and use of (organizational) knowledge, in order to reach organizational objectives”, for Schreiber et. al. (2000) it is “a framework and tool set for improving the organizational knowledge infrastructure, aimed at getting the right knowledge to the right people in the right form at the right time”. There are two major types of knowledge (POLANYI, 1966), tacit knowledge, which is difficult to articulate, tending to reside “within the heads of knowers”; and explicit knowledge, that has been captured in media, like text, audio or images (DALKIR, 2005; NONAKA & TAKEUCHI, 1997). Thus, according to Dalkir (2005), roughly 80% of our knowledge is in tacit form, leaving a 15 to 20% to explicit knowledge that has been captured or codified. It has been suggested that Knowledge Management strategies are more and more important for organizations, in this sense, the knowledge creation process, namely the SECI (Socialization, Externalization, Combination and Internalization) process is vital in order to improve competitive advantage (NONAKA & TAKEUCHI, 1997). Some strategies related to knowledge creation are the training, mentoring and tutoring programs, where workers develop collaboration initiatives through knowledge sharing and organizational learning. In service production, training programs are more complex to manage, since they are labor and knowledge intensive; on the other hand, service intangibility, simultaneity and nonstockability, provide a high uncertainty level and non-linear behavior; all of these, relying heavily on worker’s tacit knowledge, thus, slowing the codification process, which is part of the training program. This paper present, through a System Dynamics simulation model, the influence that training strategies could have in service organizations’ overall performance. 4. System Dynamics (SD) System Dynamics (SD) was developed by J. Forrester in 1961 (FORRESTER, 1989), as a methodology for understanding complex systems behavior, through soft and hard simulation. According to Sterman (2000): “System Dynamics is a perspective and set of conceptual tools that enable us to understand the structure and dynamics of complex systems. System Dynamics is also a rigorous modeling method that enables us to build formal computer simulations of complex systems and use them to design more effective policies and organizations” It evolved from the application of control theory to the study of dynamic social systems, its premise is that the behavior of a complex dynamic system is the result of the structure (causal relationships, feedback loops and time delays) (STERMAN, 2000; OLIVA & STERMAN, 2001). Through SD modeling and simulation techniques, it is possible to develop new understanding and mental models related to the complex system in study, thus, creating a “Systems Thinking” view. In that sense, SD is strongly related to “systems thinking” (FORRESTER, 1994; RICHMOND, 1994) that is “art and science of making reliable inferences about behavior by developing an increasingly deep understanding of underlying structure” (RICHMOND, 1994). 5. Insights from the practice field Following that logic, this paper proposes to get some insights from practice, in order to better understand Knowledge Management efforts in service production systems, using a System Dynamics approach. The study was made in a Software-development company in the city of Florianopolis/SC, Brazil, whose core products are for the accounting market. The company is structured in two main areas, Management, which is composed by Marketing and Financial Areas, and Technical, composed by R&D, Mediation and Technical Support Areas. The focus of this paper will be the company’s Technical Support, due to its importance in the service delivery, and the complexity of the activities made by their Technical staff. Specifically, the technical visits made to customers. In order to create a simple but complete-as-possible model, there were selected two of the decision areas presented by Chase et. al. (2004): a Customer Management Model (CMM) and Workforce Management Model (WMM). Also, considering the two basic organization’s goals, introduced on Point 2 (BERRY et. al., 1995): “to get and to keep customers” and to “make a profit”, a Financial Management Model (FMM) will be selected too. In order to analyze the dynamics of the model, a Service Production Model (SPM) will be also included. And finally a Knowledge Management Model (KMM) composed by the tacit and explicit concepts. The complete System Dynamics’ Model is presented in Fig. 1, including the submodels: CMM, WMM, FMM, SPM and KMM. In the next point, each one of them will be detailed and explained. The model will be evaluated in three different scenarios related to Workforce Training investment policy: Possibly Over-Optimistic (POO), Perhaps All Likely (PAL), and Possibly Over-Pessimistic (POP). The output variables selected for comparison purposes will be: Quantity of Customers, Mean Monthly Income, Mean Monthly Expenses, Accumulated Income less Expenses, Explicit Knowledge stock and Tacit Knowledge stock, those last two being non-dimensional variables. The period for simulation was stated in 48 months. In the SP Model, service demand depends on the comparison between the competitors Lead Time and the own Lead Time. Service delivery depends on the quantity of workforce and on its quality, through productivity. In the CM Model, the input flow depends on a word-of-mouth (wom) multiplier and on the satisfaction perceived on actual customers. In this model, satisfaction only depends on the rate between new services inflow and service delivery outflow. In the Workforce Model, the structure is as follows, the inflow of new workers depends on the firing and additional hiring policies, the experienced workers depends on the quantity of new workers and on the time for “gaining” experience through training, the outflow depends on a rate of hiring workers each month. Fixed costs are dependable of salaries and of number of trainings developed monthly. In the FM Model, both income and expenses are calculated relying on the quantity of services delivered, considering both variable and fixed costs. In the KM Model, the explicit and tacit knowledge are modeled, considering the “knowledge creation and transfer” to workforce in terms of monthly trainings. Also considering the loss of “knowledge converted” produced by firing policy and by the 80/20 rule explained by Dalkir (2005). Serv ice Production Model Demanda de Serv ico Contratacoes adicionais Gerando demanda de serv ico Prestando serv ico Lead Time ~ Lead Time Concorrencia FuncAmadores prestando serv ico Demanda por cliente por mes Produtiv idade Func Am Func com experiencia prestando serv ico Customer Management Model Produtiv idade Func Exp Workf orce Model Clientes Taxa de Demissao Contratacoes adicionais Func com experiencia Func Iniciantes Ganhando clientes Perdendo Clientes Contratando Boca a Boca ~ Ganhando experiencia Demitindo Func Taxa de perda de clientes Taxa de Perda por LeadTime Satisf acao Quantidade de Força de Trabalho Taxa Base de Perda Lead Time Gerando demanda de servico Knowledge Management Model Financial Management Model Taxa de perda de conh exp Receitas Acumuladas Prestando servico Rec Med Conhecimento Tacito Taxa de perda de conh tac Ganhando R$ Preco Saldo ConhTac Perdido Criac Conh Tac Conhecimento Explicito Despesa Acumulada CVU Conh Exp Perdido Criac conh Exp Gastando R$ ~ ~ Rap extracao ConhTac Rapidez de extracao do ConhExp Desp Med CF Taxa de Aprov eitamento Quantidade de Força de Trabalho No de Treinamentos Salarios Custos por Treinamento Figure 1. SD Model of the Service Production System in study: Technical visits 1 Possibly Over-Optimistic (POO) scenario This scenario presents ten (10) monthly trainings, considered to be high in training investment; the results obtained are presented in Fig. 2 and Fig 3. Only after the first 48 months that income and expenses are balanced. The quantity of customers falls to 43 and then rises back to 68. The summary of the results are presented in Table 1. 1: Ganhando R$ 1: 2: 3: 4: 2: Gastando R$ 3: Saldo 4: Clientes 40000 50000 100 1 2 1 2 3 1: 2: 3: 4: 20000 10000 70 2 2 1: 2: 3: 4: 0 -30000 40 3 3 4 4 1 3 1.00 Page 2 4 4 1 12.75 24.50 Months 36.25 48.00 5:15 PM Fri, Feb 16, 2007 Indicadores I - Escenario Otimista Figure 2 – Financial and Customer indicators - POO 1: Conhecimento Explicito 1: 2: 2: Conhecimento Tacito 450 1 1: 2: 2 225 1 2 1 1: 2: 1 0 2 2 1.00 12.75 24.50 Months Page 1 36.25 48.00 4:57 PM Fri, Feb 16, 2007 Untitled Figure 3 – Knowledge indicators - POO 2 Possibly Over-Pessimistic (POP) scenario This scenario presents one (1) monthly training, considered to be low in training investment; the results obtained are presented in Fig. 4 and Fig. 5. The accumulated balance after 48 months simulation surpasses –R$ 300.000, this is explained because Income was always less than Expenses. Customers fall to 55 after 48 months simulation. The summary of the results are presented in Table 1. 1: Ganhando R$ 1: 2: 3: 4: 2: Gastando R$ 3: Saldo 4: Clientes 40000 50000 100 2 3 3 2 1: 2: 3: 4: 1 3 20000 -150000 65 1 2 4 3 1 4 1: 2: 3: 4: 2 0 -350000 30 4 1.00 Page 2 4 1 12.75 24.50 Months 36.25 48.00 5:17 PM Fri, Feb 16, 2007 Indicadores I - Escenario Pessimista Figure 4 – Financial and Customer indicators - POP 2: Conhecimento Tacito 1: Conhecimento Explicito 1: 2: 4 0 1 1 1 1: 2: 2 0 1: 2: 0 0 1 2 2 1.00 2 12.75 2 36.25 48.00 5:09 PM Fri, Feb 16, 2007 24.50 Months Page 1 Untitled Figure 5 – Knowledge indicators - POP 3 Perhaps all-likely (PAL) scenario This scenario presents five (5) monthly trainings, considered to be reasonable training investment, the results obtained are presented in Fig. 6 and Fig. 7. After the first 14 months simulation, Income and Expenses are balanced, and customers quantity falls to 66. 1: Ganhando R$ 1: 2: 3: 4: 2: Gastando R$ 3: Saldo 4: Clientes 40000 75000 100 1 2 2 1 1: 2: 3: 4: 20000 30000 70 3 2 4 4 1 3 2 1: 2: 3: 4: 0 -15000 40 4 1 3 1.00 3 12.75 4 24.50 Months Page 2 36.25 48.00 5:20 PM Fri, Feb 16, 2007 Indicadores I - Escenario Esperado Figure 6 – Financial and Customer indicators - PAL 2: Conhecimento Tacito 1: Conhecimento Explicito 1: 2: 400 200 1: 2: 200 100 1 2 1 1 1: 2: 0 0 1 1.00 Page 1 2 2 2 12.75 24.50 Months 36.25 48.00 5:20 PM Fri, Feb 16, 2007 Untitled Figure 7 – Knowledge indicators - PAL The summary of the results for all three scenarios are presented in Table 1: Item Units Customers Customers Mean monthly income R$ Mean monthly expense R$ Accumulated balance R$ Accumulated Explicit knowledge w/o u. Accumulated Tacit knowledge w/o u. Source: Simulations on the SD model POO scenario 68 23.743 22.839 43.417 POP scenario 55 15.647 22.107 -310.085 PAL scenario 66 22.841 21.444 67.052 440 3 366 321 0 143 Table 1. Summary of the results obtained in the output indicators 6. Conclusions The model presented in this paper helps managers and specially operations managers to make decisions more securely, by gaining the flight-simulation capability to test different policies and to analyze its results. The model replicates some outcomes presented in real life, such as hiring and firing policies and its effects on the organizational knowledge and the customer gaining-losing dynamic. The model also captures the essence of the knowledge management dynamics, related to investments in training as a positive reinforcing cycle aimed to obtain better service quality. Specifically, the best results (see Table 1) are obtained through high training investment (POO policy), however the PAL scenario also presents relatively good results, especially when considering that the investment in training is reduced at half of the latter, since the Fixed Costs depend on the number of trainings. Considering the model above, it is reasonable to sustain that System Dynamics methodology, tools and techniques contribute positively to Operations Management, by showing a broader view of production systems, and in service production systems in special, were its core characteristics often difficult modeling and simulation. References CHASE, R.; AQUILANO, N.; JACOBS, R. Administración de Producción y Operaciones, 10ª Ed. McGraw Hill Interamericana Editores S.A., México. 2004. DALKIR, K. Knowledge Management in theory and practice. Elsevier. 2005. DAVENPORT, T. H.; PRUSAK, L. Conhecimento empresarial: como as organizações gerenciam o seu capital intelectual. Tradução de Lenke Peres. Rio de Janeiro: Campus, 1998. DRUCKER, P. F. La sociedad post-capitalista. Ed. Sudamericana. 1999. FITZSIMMONS, J. A.; FITZSIMMONS, M. J. Operations, Strategy, and Information Technology. 2. ed. McGraw Hill 1997. 613 p FORRESTER, J. System Dynamics, Systems Thinking and Soft OR. System Dynamics Review. Vol. 10, n. 2. 1994. FORRESTER, J. The beginning of System Dynamics. In International meeting of System Dynamics Society, Sttutgart, Germany. 1989. GIANESI I. G. N.; CORREA H. L. Administração estratégica de serviços : operações para a satisfação do cliente. São Paulo: Atlas, 1994. HAMMER, M.; LEONARD, D., DAVENPORT, T.H. Why don’t we know more about knowledge? MIT Sloan Management Review, Cambridge Vol.4, n. 45, p. 14-18, 2004. NONAKA, I. & TAKEUCHI, H. Criação de Conhecimento na Empresa. Rio de Janeiro, Campus, 1997 OLIVA, R. & STERMAN, J.D. Cutting corners and working overtime: Quality erosion in the service industry. Management Science. Vo. 47, n. 7, p. 894-914, 2001. RICHMOND, B. System Dynamics/System Thinking: Let’s just get on with it. International System Dynamics Conference. Sterling, Scotland. 1994 ROTH, A. V., MARUCHECK, A. S., KEMP, A., TRIMBLE, D. The knowledge factory for accelerated learning practices. Planning Review. Vol. 22, n. 3, p. 36-46, 1994. SCHREIBER, G; AKKERMANS, H.; ANJEWIERDEN, A.; De HOOG, R.; SHADBOLT, N., VAN DE VELDE, W.; WIELINGA, B. Knowledge Engineering and Management : The CommonKADS Methodology, Cambridge : MIT Press, 2002. SLACK, N. Operations Strategy, will it ever realize it´s potencial? Gestão e Produção. Vol. 12, n. 3, p. 323-332, 2005. STERMAN, J.D. Business Dynamics. Systems Thinking and Modeling for a complex world. Boston. Mc Graw Hill Higher Education, 2000.

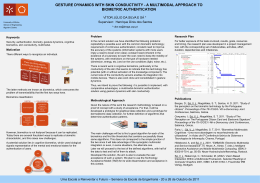

Baixar