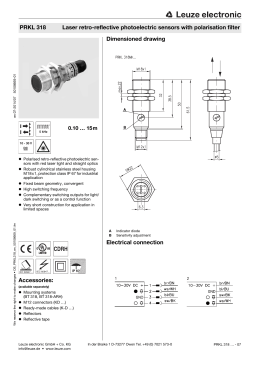

Using Longitudinal Waves Generated by Pulsed Laser Shocks for Characterization of Films of AlN/Al J. F. M. C. Pinto1, A. R. Costa1, F. S. L. Cassino1, P-Y. Jouan2, A. Tricoteaux3 1 Rede Temática de Materiais (Redemat)/Universidade Federal de Ouro Preto (UFOP) 2 Institut des Matériaux Jean Rouxel - Nantes– France, 3 Université de Valenciennes et du Hainaut-Cambrésis – France. The characterization of materials using mechanical waves (longitudinal waves, shear and surface waves) generated by shock pulsed laser has been used for many years in solids. This technique can be applied in various situations, such as assessment of porosity in ceramic materials, in determining the rolling direction and the grain size of metallic materials, surveying elastic constants, evaluating stress residual, etc. Using the mechanism of confined plasma source for generating mechanical waves, provided by Nd: YAG pulsed laser, expected to feature films, aluminum nitride (AlN) deposited on substrates of aluminum (Al) with different crystallographic orientations and textures, especially considering the adhesion of the film and the influence of texture and crystallographic orientation of crystals of the Al deposition. The attenuation of mechanical energy transient and information such as speed of the waves and the total energy involved are analyzed to evaluate the properties of the AlN thin film deposited on Al crystals. Influence of crystallographic orientation of Al on the film deposition associated with these properties. The AlN films were deposited on substrates of Al according to procedures developed and described by (Adamczyk, 2008). The substrates (commercial purity aluminum, 10 mm diameter) were obtained by solidification under appropriate conditions of heat extraction to obtain arrays of grains with different crystallographic orientations. A typical experimental setup with a pulse Nd: YAG laser system and the substrate / film is shown in figure 1. Fig. 1: Description of experimental apparatus for the generation and interpretation of mechanical waves within the system substrate / film. The photons from the laser pass through a converging lens. The substrate is exactly the focal length of lens. Longitudinal waves are generated by the confinement of the plasma that is produced from the interaction of photons with the surface of Al substrate (surface opposite to the deposited film). This surface is covered by a thin layer of absorbent carbon, to improve the absorption of photons. After the shock produced by the expanding plasma, a longitudinal mechanical wave propagates within the system substrate / film and quickly suffers attenuation effects. The analysis of this phenomenon provides dates for evaluating the mechanical properties of the components of the system substrate / film. Other interpretations may lead to assess the quality of adhesion. Once done the conventional characterization (morphology, mainly via SEM and EBSD) (COSTA, 2009), this characterization form the basis for the interpretation of acoustic phenomena recorded on the oscilloscope, from the experiment with the pulsed laser. Key words: Laser Nd: YAG, mechanical waves, elastic properties. [1] ADAMCZYK, J., HORNY, N., TRICOTEAUX, A., JOUAN, P.-Y., ZADAM, M., Appl. Surf. Science, 254, 1744, 2008. [2] COSTA, A. R.,CASSINO, F. S. L., PINTO, J. F. M. C., JOUAN, P.-Y., TRICOTEAUX, A., Morfologia e comportamento tribológico de AlN Depositado Sobre alumínio: Influência da Orientação Cristalográfica do Substrato, In: CONGRESSO ANUAL DA ABM, 64., 2009, Belo Horizonte. Anais, 2009. 1 CD. [3] POPOVICS, J. S., disponível em: www.gatewaycoalition.org/files/NewEH/htmls/Popovic. pdf, Acessado em: 17/08/2009, 09:30h. [4] ROSA G; OLTRA, R; NADAL, M.-H; Laser induced decohesion of coatings: probing by laser ultrasonics, Ultrasonics, 40, p. 765–769, 2002. [5] ROSA, G., PSYLLAKI; P., OLTRA, R., COSTIL, C., CODDET, S., Silmultaneous laser generation and laser ultrasonic detection of the mechanical breakdown of a coating-substrate interface, Ultrasonics, 39, p. 355-365, 2001. E-mail: [email protected]/ Address: Laboratório de Engenharia de Superfícies e Técnicas Afins (LESTA), Departamento de Engenharia Metalúrgica e de Materiais (DEMET), Universidade Federal de Ouro Preto (UFOP). Ouro Preto/MG. CEP.: 35400-000. Tel.: 3559-1103.

Baixar