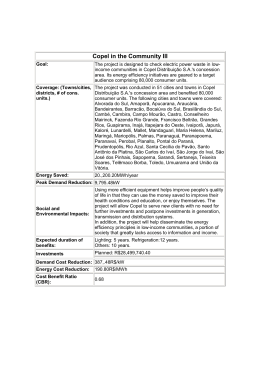

Influence of variation the temperature in the characterization of one aspect of the fractures of aluminum alloy for application in electric wires and cables A. L. M. Macapuna1, W. L. R. Santos2, P. S. Nogueira3, A. T. M. D. Souza4, and J. M. V. Quaresma5 1, 2, 3, 4, 5 Federal University of Pará, PA, Brazil In the most applications the alloys of aluminum overcame the materials competitors due yours properties mechanics and electrics be satisfactory, promoting your good acceptance in word market, in special for the use for transmission and distribution the electric energy. The objectify this paper is estimate the different temperatures in the aspect of fracture an alloy diluted Al-Fe-Cu-Si-Zr, by SEM (scanning electron microscope). The initiation this study begins with fusion of alloy in crucible of silicon carbide in the solidified in the mold “U”. soon after mold releasing the profiles obtained were machined and then process to cold rolling for dimensions [4,0; 3,8; 3,0 e 2,7]mm. The tests specimen shape wires were submitted heat treatment at various temperatures. In the investigation of the properties of the alloy were used the following temperatures [230; 310; 390]ºC during the time interval of 1 hour. The temperature of 230 ° C for 1 hour followed the requirement COPEL (Paranaense Company of Energy) in which the leagues to be classified as heat-resistant its LRT should not vary by more than 10%. The temperatures [310 and 390] ° C was adopted in view of findings in the specialty literature and as a test to check the performance of the alloy with respect to the LRT and electrical conductivity. Keywords: Properties mechanics, properties electrics, heat treatment, fracture. Work supported by Eletronorte, CNPq and PPGEM-PA. [1] L.H. Van Vlack, Principles of Materials Science and Technology (2003) 224-228. [2] ASM Metals Handbook Volume 12 – Fractography (1987). [3] M. A. Meyers and K. K. Chawla, Mechanical Behavior of Materials (2009) 571-579. [4] Cavalcante, F. A. J. - Influência do Zr sobre o binário diluído Al-0,25%Fe quanto à termorresistividade, Trabalho de conclusão de curso apresentado ao Colegiado do Curso de Engenharia Mecânica da UFPA para a obtenção do grau de Engenheiro Mecânico, II / 2005. [5] Copel – Paranaense Company of Energy [email protected], Universidade Federal do Pará, Faculdade de Engenharia Mecânica, Grupo de Pesquisa em Engenharia dos Materiais, Rua Augusto Corrêa, 01, CEP: 66075-110, Caixa postal 479, Belém, Pará, Brasil.

Baixar