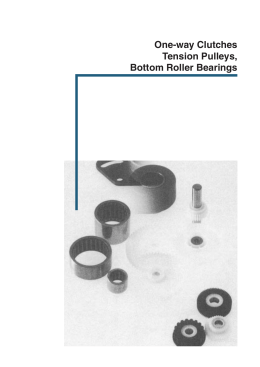

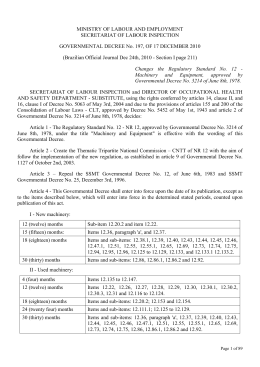

S c h a e f f l e r G r o u p As a family business, we realize that we have a responsibility to keep moving forward in a world, which is developing at a faster and faster rate and on which the half-life of forecasts is becoming increasingly shorter. As the Schaeffler Group, we must be competitive and work together to achieve our goals. We have worked hard to get to the top; and INA, FAG and LuK have grown together to form the Schaeffler Group. We are committed to succeeding, to ensuring sustainability in our actions and to being passionate about our company: “Together we move the world.” We further the competence of our employees and rely on targeted investments in research and development. We base our decisions on customers' expectations and our customers demand proximity in growing and newly developing markets. Technical and business expertise and Modern dual-clutch transmissions increase drivetrain efficiency by combining the fuel economy of a manual transmission with the comfort of an automatic. They offer an excellent foundation for progressively hybridizing the drivetrain on modular basis - from mild to full hybrid. the dedication of our excellent employees have always been Clutch Systems Innovative Solutions for All Roads a basis for our success, as have been our regional ties that have never lost sight of the global picture. Not only has our development been characterized by responsible management and consistent company development, we have also actively designed the connection between the company history and the corporate culture. We cultivate commitment, trust and reliability, striving for powerful and sustainable results. Maria-Elisabeth Schaeffler Partner Georg F. W. Schaeffler L/OE-MT7365.07.08 Printed in Brazil Partner All data have been carefully elaborated and checked. Dr. Jürgen M. Geissinger Schaeffler Brasil Ltda. However, we are not liable for any errors or omissions. President & CEO Av. Independência, 3500 A We reserve the right to introduce modifications due 18087-101 – Sorocaba – SP to technology improvements. Vendas Automotivas OEM LuK © By Schaeffler Brasil Ltda.- 2008, July. Tel.: 15 3335-1500 Any reproduction, even partial, may be only carried www.schaeffler.com.br out with our prior consent. Automotive Engine Systems Transmission Systems Chassis Systems Automotive Aftermarket Industrial Heavy Industry Production Machinery Power Transmission Railway Industry Consumer Products and Distribution Aerospace Airplanes, Helicopters and Special Applications S c h a e f f l e r G r o u p As a family business, we realize that we have a responsibility to keep moving forward in a world, which is developing at a faster and faster rate and on which the half-life of forecasts is becoming increasingly shorter. As the Schaeffler Group, we must be competitive and work together to achieve our goals. We have worked hard to get to the top; and INA, FAG and LuK have grown together to form the Schaeffler Group. We are committed to succeeding, to ensuring sustainability in our actions and to being passionate about our company: “Together we move the world.” We further the competence of our employees and rely on targeted investments in research and development. We base our decisions on customers' expectations and our customers demand proximity in growing and newly developing markets. Technical and business expertise and Modern dual-clutch transmissions increase drivetrain efficiency by combining the fuel economy of a manual transmission with the comfort of an automatic. They offer an excellent foundation for progressively hybridizing the drivetrain on modular basis - from mild to full hybrid. the dedication of our excellent employees have always been Clutch Systems Innovative Solutions for All Roads a basis for our success, as have been our regional ties that have never lost sight of the global picture. Not only has our development been characterized by responsible management and consistent company development, we have also actively designed the connection between the company history and the corporate culture. We cultivate commitment, trust and reliability, striving for powerful and sustainable results. Maria-Elisabeth Schaeffler Partner Georg F. W. Schaeffler L/OE-MT7365.07.08 Printed in Brazil Partner All data have been carefully elaborated and checked. Dr. Jürgen M. Geissinger Schaeffler Brasil Ltda. However, we are not liable for any errors or omissions. President & CEO Av. Independência, 3500 A We reserve the right to introduce modifications due 18087-101 – Sorocaba – SP to technology improvements. Vendas Automotivas OEM LuK © By Schaeffler Brasil Ltda.- 2008, July. Tel.: 15 3335-1500 Any reproduction, even partial, may be only carried www.schaeffler.com.br out with our prior consent. Automotive Engine Systems Transmission Systems Chassis Systems Automotive Aftermarket Industrial Heavy Industry Production Machinery Power Transmission Railway Industry Consumer Products and Distribution Aerospace Airplanes, Helicopters and Special Applications S c h a e f f l e r G r o u p As a family business, we realize that we have a responsibility to keep moving forward in a world, which is developing at a faster and faster rate and on which the half-life of forecasts is becoming increasingly shorter. As the Schaeffler Group, we must be competitive and work together to achieve our goals. We have worked hard to get to the top; and INA, FAG and LuK have grown together to form the Schaeffler Group. We are committed to succeeding, to ensuring sustainability in our actions and to being passionate about our company: “Together we move the world.” We further the competence of our employees and rely on targeted investments in research and development. We base our decisions on customers' expectations and our customers demand proximity in growing and newly developing markets. Technical and business expertise and Modern dual-clutch transmissions increase drivetrain efficiency by combining the fuel economy of a manual transmission with the comfort of an automatic. They offer an excellent foundation for progressively hybridizing the drivetrain on modular basis - from mild to full hybrid. the dedication of our excellent employees have always been Clutch Systems Innovative Solutions for All Roads a basis for our success, as have been our regional ties that have never lost sight of the global picture. Not only has our development been characterized by responsible management and consistent company development, we have also actively designed the connection between the company history and the corporate culture. We cultivate commitment, trust and reliability, striving for powerful and sustainable results. Maria-Elisabeth Schaeffler Partner Georg F. W. Schaeffler L/OE-MT7365.07.08 Printed in Brazil Partner All data have been carefully elaborated and checked. Dr. Jürgen M. Geissinger Schaeffler Brasil Ltda. However, we are not liable for any errors or omissions. President & CEO Av. Independência, 3500 A We reserve the right to introduce modifications due 18087-101 – Sorocaba – SP to technology improvements. Vendas Automotivas OEM LuK © By Schaeffler Brasil Ltda.- 2008, July. Tel.: 15 3335-1500 Any reproduction, even partial, may be only carried www.schaeffler.com.br out with our prior consent. Automotive Engine Systems Transmission Systems Chassis Systems Automotive Aftermarket Industrial Heavy Industry Production Machinery Power Transmission Railway Industry Consumer Products and Distribution Aerospace Airplanes, Helicopters and Special Applications Pr o d u c t i o n P r o d u c t s Gearing up for Tomorrow LuK supplies components and areas, LuK can look back on a legacy LuK is also an important supplier of systems for vehicle drivetrains of having developed many ground- many other products, such as around the world. When Georg and breaking innovations. In 1965, LuK hydraulic cylinders. Wilhelm Schaeffler founded LuK in was the first company in Europe to OEM Automotive and Agricultural 1965, their objective was to produce market a diaphragm spring clutch. Business focuses on new clutch cover with diaphragm spring Twenty years later, LuK launched the developments and stands for systems for the successor of the VW first dual-mass flywheel. This was excellence in supply to Beetle. Today, LuK clutches are used followed by the introduction of manufacturers. The Automotive in one in four cars worldwide. With components for CVTs that could Aftermarket business unit, created innovative products and lean, handle more than 300 Nm of torque, by LuK, is currently responsible for customer-oriented structures, LuK is as well as Auto Shift Gearbox (ASG)- the entire automotive aftermarket experiencing highly dynamic growth. the world's first electromagnetically- business of the Schaeffler Group, Almost all major automobile automated manual gearbox. In 1997, and supplies a large variety of manufacturers benefit from the LuK began engineering and products of the INA, FAG and LuK knowledge of LuK engineers. manufacturing torque converters in brands - about 20 thousand Dedicated employees, innovation, the US; Germany followed in 2004. different items of original product development and LuK's current R&D efforts, in replacement parts, moreover technological leadership are the addition to the continued remanufactured products. The main factors of the company's development of conventional company offers comprehensive success. LuK makes project teams transmission systems, have a services to distributors, available to all its customers to particular focus on alternative wholesalers, repair shops and ensure that specific requirements drivetrain concepts, such as exclusive car dealers, including a are met. components for dual-clutch strong technical assistance As a technology leader in many transmissions and hybrid drivetrains. program. Machining Stamping Clutch Assembly Heat Treatment Clutch Release System Assembly a n d S e r v i c e s D e v e l o p m e n t 3 5 7 combinations, which keep the 6 actuation process smooth and silent. Global Presence, Local Solutions 1. Engine Flywheel Technology – reference in trial technology and Dual Mass Flywheels (DMF) supplies analysis and expert reports The current development on for all other operations of the LuK ment of slave cylinders applies LuK has always been present and close to other countries and our headquarters in internal combustion engines lead Group. plastic materials integrating its customers by locally developing, Germany, provided a regular diffusion of functions, assuring low weight and testing and manufacturing its products in knowledge and allows the reduction of the innovating in the use of such order to meet the markets needs and response time to technical challenges. materials. overcome its partners’ expectations. The LuK stands for its special attention to its 4 In the same manner, the develop- the new projects for systems, which operates at lower rotations, higher 3. Conventional and Self-Adjusting compression rates and less mass. Clutches (SAC) New eco-friendly fuels change the The trend of increasing the engine systems’ torsional features. on comfort require clutches capable by reduction of running and wind to transmit a high torque on one noise sources are increasing and 9 torques and the growing demands Vehicles are constantly optimized noises. As a consequence, internal 8 1 2 hand, but featuring low operation power on the other hand. The operations in Sorocaba, Brazil, count on a partners and strives for local solutions 8. Piping-Easy Installation with comprehensive structure to attend new with global knowledge and technology. Innovation projects requirements, from its conception Modern dual-clutch transmissions improve On request, LuK coordinates the to the serial production. the transmission system's efficiency and development of pipe installation LuK’s concept is based on a customer- combines the reduction in fuel oriented work, systematically participating consumption of a manual transmission in the definition and development phases with the comfort of an automatic of the systems to uphold its products. The transmission. These transmissions offer an multidisciplinary teamwork, which excellent base to the progressive involves professional people from hybridizing of a transmission on a modular Sorocaba and the branch offices from basis - from mild to full hybrid. and the supply of components. diaphragm spring development was Besides, with the use of rubber / per the theories of physics, the the first step taken by LuK to meet steel and plastic pipes, LuK, in solution is to increment the such demands. Where as a clutch is association with technical partners, transmission inertial mass, without a wearing component in vehicles, has developed a new polymer increasing the coupling system LuK has been investing great efforts 6. Clutch Release Systems technology that allows flexibility in inertial mass. Thus, the rotation to continuously develop and Knowledge is the key to success in the installation, making easy the responsible for the system excita- improve compensation systems to users’ comfort and avoiding the clutch release systems. Vehicle quick fixing and allowing similar tion and which provokes a reso- minimize those wear effects. In premature wear of the transmission temperature distribution in opera- drivers may evaluate the clutch and routes as the cable route, with low nance, reduces below the idling 1995, LuK started the production of gears. tion conditions, as well as manufac- the release system comfort feeling volumetric expansion, reducing shift speed. the self-adjusting clutch (SAC), LuK clutches provide excellent turing process details. the smooth coupling and decoupling hydraulic losses at reduced applica- which uses a system based on a operating comfort, long operating behavior, the load-travel ratio and tion costs. 2. Centrifugal Burst Trial of load sensor to actuate the wear life, compact solutions by means of 5. Vehicle Testing Technology the absence of vibrations and noises Cylindrical Parts. compensation system and, conse- function integration, strength and Sustained by LuK's values, the during pedal actuation. When 9. Expertise in Clutch Pedal System Searching for quality excellence and quently, the effort on the clutch misaligning compensation between Experimental Engineering actuating the clutch pedal, the Projects perfection in product durability, LuK pedal. the engine and the transmission. Department is composed of a driver notes the release system Always concerned to offer the best has developed proceeding trials and Besides the clutch cover, the disc specialized team, which is highly response. To satisfy the require- technical solutions to meet the test rigs for the accelerated plays an important role in the 4. Virtual Development qualified in testing and analyzing ments on the clutch pedal, the current demands on comfort, and evaluation of centrifugal and coupling between engine and Already during the first development clutch systems and their interfaces system components must be approaching the pedal actuation centripetal forces on complex transmission. As core element of phase, LuK applies the virtual with the vehicle. Aiming to support adjusted as for the tribology load as well as noises and vibrations cylindrical components and this connection, LuK has specialized development concept on its pro- its partners in development and parameters, rigidity and mechanical during actuation, LuK has created products, thus allowing the itself in tuning of axial characteris- jects, anticipating the products' final solutions of technical obstacles, relations LuK keeps high technologi- and has been continuously enlarg- continuous improvement of our tics system, which provides modula- behavior, even before the first that may hinder the comfort and cal competence level in clutch ing its professional team with projects and the projects of our tion and clutch pedal actuation physical prototype. By means of durability of the vehicles, LuK release systems. experts specialized in pedals and Develop product partners and customers. In our R&D comfort. computer methods, such as virtual performs and develops testing load compensation springs. Develop production process Center in Sorocaba we are able to As secondary function, but not less analysis and simulations to optimize technologies for its products and 7. The Future of Cylinders Moreover, LuK shows its compe- perform component trials, such as important, clutch discs of modern the project, the research cycles of the systems they are fit in. Thus, the LuK supplies master cylinders for tence in clutch release system and engine flywheel systems, clutches developments allow the implemen- the vehicle components are reduced. tests are made on combustion the clutch release system with components, minimizing noises and and brake discs at high safety and tation of torsional dampers in its In other words, LuK anticipates the engines, transmission noises and complete plastic project technology. vibrations, using technologies reliability levels. With local knowl- core part, which dampen the definitions involving the develop- stresses, as well as on comfort and In different dimensions, connection grounded on innovative solutions by edge and expertise, the R&D Center vibrations produced by the internal ment of geometry and shapes, durability of the clutch pedal and fixing systems, the cylinders use means of plastics and polymers. in Sorocaba has become a world combustion engines, improving the durability, vibrations and noises, actuation systems. piston, seal and lubricant material system dampers diminishing. As Testing Prototyping Expertise Project Tuning Product Development Process (PEP) Project Management PEP Process quotation Prepare production Volume production Definition phase Inquiry Prototype phase Quotation Optimization phase Define functions & processes Modification freeze Production prelaunch phase Internal SOP Ramp-up phase Stable production Pr o d u c t i o n P r o d u c t s Gearing up for Tomorrow LuK supplies components and areas, LuK can look back on a legacy LuK is also an important supplier of systems for vehicle drivetrains of having developed many ground- many other products, such as around the world. When Georg and breaking innovations. In 1965, LuK hydraulic cylinders. Wilhelm Schaeffler founded LuK in was the first company in Europe to OEM Automotive and Agricultural 1965, their objective was to produce market a diaphragm spring clutch. Business focuses on new clutch cover with diaphragm spring Twenty years later, LuK launched the developments and stands for systems for the successor of the VW first dual-mass flywheel. This was excellence in supply to Beetle. Today, LuK clutches are used followed by the introduction of manufacturers. The Automotive in one in four cars worldwide. With components for CVTs that could Aftermarket business unit, created innovative products and lean, handle more than 300 Nm of torque, by LuK, is currently responsible for customer-oriented structures, LuK is as well as Auto Shift Gearbox (ASG)- the entire automotive aftermarket experiencing highly dynamic growth. the world's first electromagnetically- business of the Schaeffler Group, Almost all major automobile automated manual gearbox. In 1997, and supplies a large variety of manufacturers benefit from the LuK began engineering and products of the INA, FAG and LuK knowledge of LuK engineers. manufacturing torque converters in brands - about 20 thousand Dedicated employees, innovation, the US; Germany followed in 2004. different items of original product development and LuK's current R&D efforts, in replacement parts, moreover technological leadership are the addition to the continued remanufactured products. The main factors of the company's development of conventional company offers comprehensive success. LuK makes project teams transmission systems, have a services to distributors, available to all its customers to particular focus on alternative wholesalers, repair shops and ensure that specific requirements drivetrain concepts, such as exclusive car dealers, including a are met. components for dual-clutch strong technical assistance As a technology leader in many transmissions and hybrid drivetrains. program. Machining Stamping Clutch Assembly Heat Treatment Clutch Release System Assembly a n d S e r v i c e s D e v e l o p m e n t 3 5 7 combinations, which keep the 6 actuation process smooth and silent. Global Presence, Local Solutions 1. Engine Flywheel Technology – reference in trial technology and Dual Mass Flywheels (DMF) supplies analysis and expert reports The current development on for all other operations of the LuK ment of slave cylinders applies LuK has always been present and close to other countries and our headquarters in internal combustion engines lead Group. plastic materials integrating its customers by locally developing, Germany, provided a regular diffusion of functions, assuring low weight and testing and manufacturing its products in knowledge and allows the reduction of the innovating in the use of such order to meet the markets needs and response time to technical challenges. materials. overcome its partners’ expectations. The LuK stands for its special attention to its 4 In the same manner, the develop- the new projects for systems, which operates at lower rotations, higher 3. Conventional and Self-Adjusting compression rates and less mass. Clutches (SAC) New eco-friendly fuels change the The trend of increasing the engine systems’ torsional features. on comfort require clutches capable by reduction of running and wind to transmit a high torque on one noise sources are increasing and 9 torques and the growing demands Vehicles are constantly optimized noises. As a consequence, internal 8 1 2 hand, but featuring low operation power on the other hand. The operations in Sorocaba, Brazil, count on a partners and strives for local solutions 8. Piping-Easy Installation with comprehensive structure to attend new with global knowledge and technology. Innovation projects requirements, from its conception Modern dual-clutch transmissions improve On request, LuK coordinates the to the serial production. the transmission system's efficiency and development of pipe installation LuK’s concept is based on a customer- combines the reduction in fuel oriented work, systematically participating consumption of a manual transmission in the definition and development phases with the comfort of an automatic of the systems to uphold its products. The transmission. These transmissions offer an multidisciplinary teamwork, which excellent base to the progressive involves professional people from hybridizing of a transmission on a modular Sorocaba and the branch offices from basis - from mild to full hybrid. and the supply of components. diaphragm spring development was Besides, with the use of rubber / per the theories of physics, the the first step taken by LuK to meet steel and plastic pipes, LuK, in solution is to increment the such demands. Where as a clutch is association with technical partners, transmission inertial mass, without a wearing component in vehicles, has developed a new polymer increasing the coupling system LuK has been investing great efforts 6. Clutch Release Systems technology that allows flexibility in inertial mass. Thus, the rotation to continuously develop and Knowledge is the key to success in the installation, making easy the responsible for the system excita- improve compensation systems to users’ comfort and avoiding the clutch release systems. Vehicle quick fixing and allowing similar tion and which provokes a reso- minimize those wear effects. In premature wear of the transmission temperature distribution in opera- drivers may evaluate the clutch and routes as the cable route, with low nance, reduces below the idling 1995, LuK started the production of gears. tion conditions, as well as manufac- the release system comfort feeling volumetric expansion, reducing shift speed. the self-adjusting clutch (SAC), LuK clutches provide excellent turing process details. the smooth coupling and decoupling hydraulic losses at reduced applica- which uses a system based on a operating comfort, long operating behavior, the load-travel ratio and tion costs. 2. Centrifugal Burst Trial of load sensor to actuate the wear life, compact solutions by means of 5. Vehicle Testing Technology the absence of vibrations and noises Cylindrical Parts. compensation system and, conse- function integration, strength and Sustained by LuK's values, the during pedal actuation. When 9. Expertise in Clutch Pedal System Searching for quality excellence and quently, the effort on the clutch misaligning compensation between Experimental Engineering actuating the clutch pedal, the Projects perfection in product durability, LuK pedal. the engine and the transmission. Department is composed of a driver notes the release system Always concerned to offer the best has developed proceeding trials and Besides the clutch cover, the disc specialized team, which is highly response. To satisfy the require- technical solutions to meet the test rigs for the accelerated plays an important role in the 4. Virtual Development qualified in testing and analyzing ments on the clutch pedal, the current demands on comfort, and evaluation of centrifugal and coupling between engine and Already during the first development clutch systems and their interfaces system components must be approaching the pedal actuation centripetal forces on complex transmission. As core element of phase, LuK applies the virtual with the vehicle. Aiming to support adjusted as for the tribology load as well as noises and vibrations cylindrical components and this connection, LuK has specialized development concept on its pro- its partners in development and parameters, rigidity and mechanical during actuation, LuK has created products, thus allowing the itself in tuning of axial characteris- jects, anticipating the products' final solutions of technical obstacles, relations LuK keeps high technologi- and has been continuously enlarg- continuous improvement of our tics system, which provides modula- behavior, even before the first that may hinder the comfort and cal competence level in clutch ing its professional team with projects and the projects of our tion and clutch pedal actuation physical prototype. By means of durability of the vehicles, LuK release systems. experts specialized in pedals and Develop product partners and customers. In our R&D comfort. computer methods, such as virtual performs and develops testing load compensation springs. Develop production process Center in Sorocaba we are able to As secondary function, but not less analysis and simulations to optimize technologies for its products and 7. The Future of Cylinders Moreover, LuK shows its compe- perform component trials, such as important, clutch discs of modern the project, the research cycles of the systems they are fit in. Thus, the LuK supplies master cylinders for tence in clutch release system and engine flywheel systems, clutches developments allow the implemen- the vehicle components are reduced. tests are made on combustion the clutch release system with components, minimizing noises and and brake discs at high safety and tation of torsional dampers in its In other words, LuK anticipates the engines, transmission noises and complete plastic project technology. vibrations, using technologies reliability levels. With local knowl- core part, which dampen the definitions involving the develop- stresses, as well as on comfort and In different dimensions, connection grounded on innovative solutions by edge and expertise, the R&D Center vibrations produced by the internal ment of geometry and shapes, durability of the clutch pedal and fixing systems, the cylinders use means of plastics and polymers. in Sorocaba has become a world combustion engines, improving the durability, vibrations and noises, actuation systems. piston, seal and lubricant material system dampers diminishing. As Testing Prototyping Expertise Project Tuning Product Development Process (PEP) Project Management PEP Process quotation Prepare production Volume production Definition phase Inquiry Prototype phase Quotation Optimization phase Define functions & processes Modification freeze Production prelaunch phase Internal SOP Ramp-up phase Stable production Pr o d u c t i o n P r o d u c t s Gearing up for Tomorrow LuK supplies components and areas, LuK can look back on a legacy LuK is also an important supplier of systems for vehicle drivetrains of having developed many ground- many other products, such as around the world. When Georg and breaking innovations. In 1965, LuK hydraulic cylinders. Wilhelm Schaeffler founded LuK in was the first company in Europe to OEM Automotive and Agricultural 1965, their objective was to produce market a diaphragm spring clutch. Business focuses on new clutch cover with diaphragm spring Twenty years later, LuK launched the developments and stands for systems for the successor of the VW first dual-mass flywheel. This was excellence in supply to Beetle. Today, LuK clutches are used followed by the introduction of manufacturers. The Automotive in one in four cars worldwide. With components for CVTs that could Aftermarket business unit, created innovative products and lean, handle more than 300 Nm of torque, by LuK, is currently responsible for customer-oriented structures, LuK is as well as Auto Shift Gearbox (ASG)- the entire automotive aftermarket experiencing highly dynamic growth. the world's first electromagnetically- business of the Schaeffler Group, Almost all major automobile automated manual gearbox. In 1997, and supplies a large variety of manufacturers benefit from the LuK began engineering and products of the INA, FAG and LuK knowledge of LuK engineers. manufacturing torque converters in brands - about 20 thousand Dedicated employees, innovation, the US; Germany followed in 2004. different items of original product development and LuK's current R&D efforts, in replacement parts, moreover technological leadership are the addition to the continued remanufactured products. The main factors of the company's development of conventional company offers comprehensive success. LuK makes project teams transmission systems, have a services to distributors, available to all its customers to particular focus on alternative wholesalers, repair shops and ensure that specific requirements drivetrain concepts, such as exclusive car dealers, including a are met. components for dual-clutch strong technical assistance As a technology leader in many transmissions and hybrid drivetrains. program. Machining Stamping Clutch Assembly Heat Treatment Clutch Release System Assembly a n d S e r v i c e s D e v e l o p m e n t 3 5 7 combinations, which keep the 6 actuation process smooth and silent. Global Presence, Local Solutions 1. Engine Flywheel Technology – reference in trial technology and Dual Mass Flywheels (DMF) supplies analysis and expert reports The current development on for all other operations of the LuK ment of slave cylinders applies LuK has always been present and close to other countries and our headquarters in internal combustion engines lead Group. plastic materials integrating its customers by locally developing, Germany, provided a regular diffusion of functions, assuring low weight and testing and manufacturing its products in knowledge and allows the reduction of the innovating in the use of such order to meet the markets needs and response time to technical challenges. materials. overcome its partners’ expectations. The LuK stands for its special attention to its 4 In the same manner, the develop- the new projects for systems, which operates at lower rotations, higher 3. Conventional and Self-Adjusting compression rates and less mass. Clutches (SAC) New eco-friendly fuels change the The trend of increasing the engine systems’ torsional features. on comfort require clutches capable by reduction of running and wind to transmit a high torque on one noise sources are increasing and 9 torques and the growing demands Vehicles are constantly optimized noises. As a consequence, internal 8 1 2 hand, but featuring low operation power on the other hand. The operations in Sorocaba, Brazil, count on a partners and strives for local solutions 8. Piping-Easy Installation with comprehensive structure to attend new with global knowledge and technology. Innovation projects requirements, from its conception Modern dual-clutch transmissions improve On request, LuK coordinates the to the serial production. the transmission system's efficiency and development of pipe installation LuK’s concept is based on a customer- combines the reduction in fuel oriented work, systematically participating consumption of a manual transmission in the definition and development phases with the comfort of an automatic of the systems to uphold its products. The transmission. These transmissions offer an multidisciplinary teamwork, which excellent base to the progressive involves professional people from hybridizing of a transmission on a modular Sorocaba and the branch offices from basis - from mild to full hybrid. and the supply of components. diaphragm spring development was Besides, with the use of rubber / per the theories of physics, the the first step taken by LuK to meet steel and plastic pipes, LuK, in solution is to increment the such demands. Where as a clutch is association with technical partners, transmission inertial mass, without a wearing component in vehicles, has developed a new polymer increasing the coupling system LuK has been investing great efforts 6. Clutch Release Systems technology that allows flexibility in inertial mass. Thus, the rotation to continuously develop and Knowledge is the key to success in the installation, making easy the responsible for the system excita- improve compensation systems to users’ comfort and avoiding the clutch release systems. Vehicle quick fixing and allowing similar tion and which provokes a reso- minimize those wear effects. In premature wear of the transmission temperature distribution in opera- drivers may evaluate the clutch and routes as the cable route, with low nance, reduces below the idling 1995, LuK started the production of gears. tion conditions, as well as manufac- the release system comfort feeling volumetric expansion, reducing shift speed. the self-adjusting clutch (SAC), LuK clutches provide excellent turing process details. the smooth coupling and decoupling hydraulic losses at reduced applica- which uses a system based on a operating comfort, long operating behavior, the load-travel ratio and tion costs. 2. Centrifugal Burst Trial of load sensor to actuate the wear life, compact solutions by means of 5. Vehicle Testing Technology the absence of vibrations and noises Cylindrical Parts. compensation system and, conse- function integration, strength and Sustained by LuK's values, the during pedal actuation. When 9. Expertise in Clutch Pedal System Searching for quality excellence and quently, the effort on the clutch misaligning compensation between Experimental Engineering actuating the clutch pedal, the Projects perfection in product durability, LuK pedal. the engine and the transmission. Department is composed of a driver notes the release system Always concerned to offer the best has developed proceeding trials and Besides the clutch cover, the disc specialized team, which is highly response. To satisfy the require- technical solutions to meet the test rigs for the accelerated plays an important role in the 4. Virtual Development qualified in testing and analyzing ments on the clutch pedal, the current demands on comfort, and evaluation of centrifugal and coupling between engine and Already during the first development clutch systems and their interfaces system components must be approaching the pedal actuation centripetal forces on complex transmission. As core element of phase, LuK applies the virtual with the vehicle. Aiming to support adjusted as for the tribology load as well as noises and vibrations cylindrical components and this connection, LuK has specialized development concept on its pro- its partners in development and parameters, rigidity and mechanical during actuation, LuK has created products, thus allowing the itself in tuning of axial characteris- jects, anticipating the products' final solutions of technical obstacles, relations LuK keeps high technologi- and has been continuously enlarg- continuous improvement of our tics system, which provides modula- behavior, even before the first that may hinder the comfort and cal competence level in clutch ing its professional team with projects and the projects of our tion and clutch pedal actuation physical prototype. By means of durability of the vehicles, LuK release systems. experts specialized in pedals and Develop product partners and customers. In our R&D comfort. computer methods, such as virtual performs and develops testing load compensation springs. Develop production process Center in Sorocaba we are able to As secondary function, but not less analysis and simulations to optimize technologies for its products and 7. The Future of Cylinders Moreover, LuK shows its compe- perform component trials, such as important, clutch discs of modern the project, the research cycles of the systems they are fit in. Thus, the LuK supplies master cylinders for tence in clutch release system and engine flywheel systems, clutches developments allow the implemen- the vehicle components are reduced. tests are made on combustion the clutch release system with components, minimizing noises and and brake discs at high safety and tation of torsional dampers in its In other words, LuK anticipates the engines, transmission noises and complete plastic project technology. vibrations, using technologies reliability levels. With local knowl- core part, which dampen the definitions involving the develop- stresses, as well as on comfort and In different dimensions, connection grounded on innovative solutions by edge and expertise, the R&D Center vibrations produced by the internal ment of geometry and shapes, durability of the clutch pedal and fixing systems, the cylinders use means of plastics and polymers. in Sorocaba has become a world combustion engines, improving the durability, vibrations and noises, actuation systems. piston, seal and lubricant material system dampers diminishing. As Testing Prototyping Expertise Project Tuning Product Development Process (PEP) Project Management PEP Process quotation Prepare production Volume production Definition phase Inquiry Prototype phase Quotation Optimization phase Define functions & processes Modification freeze Production prelaunch phase Internal SOP Ramp-up phase Stable production S c h a e f f l e r G r o u p As a family business, we realize that we have a responsibility to keep moving forward in a world, which is developing at a faster and faster rate and on which the half-life of forecasts is becoming increasingly shorter. As the Schaeffler Group, we must be competitive and work together to achieve our goals. We have worked hard to get to the top; and INA, FAG and LuK have grown together to form the Schaeffler Group. We are committed to succeeding, to ensuring sustainability in our actions and to being passionate about our company: “Together we move the world.” We further the competence of our employees and rely on targeted investments in research and development. We base our decisions on customers' expectations and our customers demand proximity in growing and newly developing markets. Technical and business expertise and Modern dual-clutch transmissions increase drivetrain efficiency by combining the fuel economy of a manual transmission with the comfort of an automatic. They offer an excellent foundation for progressively hybridizing the drivetrain on modular basis - from mild to full hybrid. the dedication of our excellent employees have always been Clutch Systems Innovative Solutions for All Roads a basis for our success, as have been our regional ties that have never lost sight of the global picture. Not only has our development been characterized by responsible management and consistent company development, we have also actively designed the connection between the company history and the corporate culture. We cultivate commitment, trust and reliability, striving for powerful and sustainable results. Maria-Elisabeth Schaeffler Partner Georg F. W. Schaeffler L/OE-MT7365.07.08 Printed in Brazil Partner All data have been carefully elaborated and checked. Dr. Jürgen M. Geissinger Schaeffler Brasil Ltda. However, we are not liable for any errors or omissions. President & CEO Av. Independência, 3500 A We reserve the right to introduce modifications due 18087-101 – Sorocaba – SP to technology improvements. Vendas Automotivas OEM LuK © By Schaeffler Brasil Ltda.- 2008, July. Tel.: 15 3335-1500 Any reproduction, even partial, may be only carried www.schaeffler.com.br out with our prior consent. Automotive Engine Systems Transmission Systems Chassis Systems Automotive Aftermarket Industrial Heavy Industry Production Machinery Power Transmission Railway Industry Consumer Products and Distribution Aerospace Airplanes, Helicopters and Special Applications

Baixar