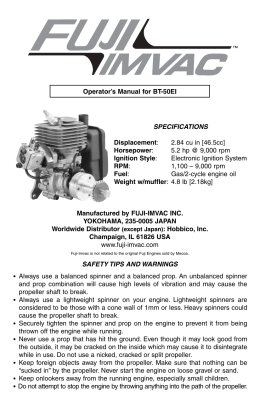

Meu Caro, Mais uma semana e mais uma ronda por temas que focam Segurança Aeronáutica. Um objectivo ao qual me propus já lá vai mais de um ano. Esta semana, como sempre, abordaremos diversos temas. OPERAÇÃO DOS MAGNETOS DO AVIÃO Quando fazes esta operação – teste dos magnetos do avião – sabes o que é que realmente estás a fazer? Com certeza que sabes. Aprendeste-o durante o teu curso de pilotagem. Mas tens as noções frescas e sem qualquer dúvida? Vá lá não gaguejes. Tens algumas dúvidas. Tratando-se dum tema que pode ter repercussões na Segurança, vamos lá tirar essas dúvidas. Começo por te perguntar: sabes o que é e para que serve o “cabo de massa” dos magnetos? Vasculha lá a tua memória! Não te recordas, mesmo? Então, vá lá. O “cabo de massa” dos magnetos é um cabo que liga um magneto à massa, impedindo-o de funcionar. Quando fazes o teste de magnetos no check “Antes da Descolagem”, o que vais testar é exactamente o “cabo de massa” dos magnetos. Um “cabo de massa” dos magnetos, desligado ou partido, em qualquer um destes magnetos, significa que a ignição não poderá ser desligada, nem em voo, nem no solo. Se o piloto não verificar qualquer queda nas RPM durante o teste de motor, isto poderá significar que o “cabo de massa” está partido. Vamos a um pouco de teoria? THE MAGNETO CHECK What Are You Looking For? By Earl C. Downs What a beautiful day for flying! You can just feel your airplane urging you to take to the sky as you taxi out for takeoff. Upon entering the run-up area you point the nose of your plane into the wind in preparation for the pretakeoff engine check. At the core of the run-up procedure is the magneto check. The engine is set to the proper rpm, and you perform the normal routine. Right mag, back to both. Left mag, back to both. After a while, this procedure of checking the magnetos almost becomes automatic. It can become so automatic that I sometimes wonder if we really know what we are looking for. Do you know what the magneto check is actually proving? Let's review this important system. Checking the magnetos (let's call them mags) is really a check of the entire ignition system. The ignition system is what causes the fuel to burn, which results in the wonderfully loud engine noise we pilots love to hear. Any ignition system on any reciprocating (piston) engine has the same basic components. There must be a source of electricity; a distributor (which tells the electricity where to go); wires to carry the electricity; and the spark plugs, which ignite the fuel. While your automobile and airplane ignition systems both accomplish the same task, the way they do it is very different. The heart of any ignition system is the electricity, and this is where the big difference between cars and airplanes shows up. Your auto ignition shares the same battery/generator electrical system with the lights, radio, starter, and every other electrical item. If the battery/generator system on your car fails, the ignition goes dead and a tow company gets some of your hard-earned money. Your airplane also has a battery/generator system, but it has nothing to do with the engine ignition system. The FAA requires that the engine ignition on airplanes must be separate from the battery/generator system. This is accomplished on most airplane engines by the use of magnetos to create the ignition electricity. Not only must the ignition be independent of the battery/generator system, but your plane also must have two ignition systems that are independent of each other. The battery and generator can be removed from the airplane and the engine will still run (you just won't have an electric starter). Those folks at the FAA are really into safety with this one! The airplane's double ignition system provides better performance because of more efficient combustion and a higher level of safety through redundancy. The magnetos produce the electrical power for the spark plugs, and these neat little gadgets have been around for more than 100 years. In its simplest form, a magneto is nothing more than a spinning magnet surrounded by a coil of wire. Have you ever seen one of those old telephones that had a hand crank on the side? The crank simply provided the turning motion to operate a magneto, which sent out enough electricity to ring the bell on the other end of the line. Modern applications of magnetos include motorcycles, weed trimmers, and wind-up radios, in addition to piston-engine airplanes. The mags on your plane are gear-driven by the engine. The same gear drive that spins the magnet also spins a distributor that sends the electricity to the correct spark plug at the right time. Each magneto has its own distributor, wires, and spark plugs. Each cylinder has two spark plugs, one for each mag. The mags are attached to the back side of the engine and are about the size of a grapefruit. They are usually painted black, and the spark plug wires come out of each mag and go to their respective plugs. There you have it - two independent ignition systems that are also independent of the battery/generator system. In order to understand what you should be looking for while performing the magneto check during the engine runup it's important to understand what the mag switch actually does. The Off position of the magneto switch is different from that of other electrical switches you use. When you switch off the radio, you are removing the electricity from the radio. The Off position of the mag switch does not actually remove electricity from the magneto because the magneto is what makes the electricity. Remember, any time the magnet in a magneto spins, we get electricity. Think about it - if you move the propeller by hand, the magneto is working. Turning the mag switch Off actually causes a short circuit (called grounding) in the magneto coil that prevents it from working. The wire that does the grounding is called a P-lead (Primary-lead) (Na nomenclatura portuguesa este P-lead designa-se por “cabo de massa”). Although the mag switch in your plane only shows one, there are really three Off positions. "Off" means that both mags are grounded and should not be able to power their ignition systems. Remember, grounding only occurs if the P-lead is connected properly. A broken Plead could cause an engine start if the prop is moved ever so slightly. The other two Off positions on the mag switch are those labeled "L" and "R". When you switch to the left mag (L) you are actually grounding the right mag. If you think about it, the only way to test the left magneto is to switch off the right magneto. (Afinal, neste caso, o que queres testar é se o magneto Esquerdo, o “left”, está a funcionar correctamente). The same holds true for the right mag (R) position. By selecting the right magneto, you shut off the left magneto. Your run-up check proves that each ignition system operates without help from the other one. The Both position of the mag switch removes the ground from both magnetos, and the engine uses the full dual system. The P-leads are key to the operation of the magnetos. A disconnected P-lead on either magneto means that the ignition cannot be shut off in flight or on the ground - and that's dangerous. Timing is adjusted separately on each magneto so that it fires its spark plugs at exactly the right time. If the plug fires too early or too late, engine power and engine life can be adversely affected. As the pilot, you don't have any way to know exactly how the mags on your plane are timed, but if your engine malfunctions there are symptoms that can give you clues if the timing is not right. Let's take a look at your magneto check during an engine runup and review each step. You need to refer to the appropriate operating manual for actual rpm numbers to use during your check. While running at the recommended power setting, switch the mags from the Both position to the R and L positions. Be sure to go back to the Both position each time you move the switch. You must see a drop in power, but it must not exceed the maximum allowable. Too great a drop in rpm can be an indication of several problems - anything from a fouled plug to a bad ignition wire to improper timing to a bad magneto. It needs to be checked by a mechanic. No drop in rpm could be an indication of a broken P-lead. You can check this yourself by bringing the engine to idle rpm and placing the ignition switch to Off. If the P-lead is broken, the engine will continue to run. If the P-leads are good, the engine will begin to quit. If it does start to quit, place the mag switch back on before the prop stops turning and the engine will restart. Another cause for little or no rpm drop could be improper magneto timing. When in doubt, have it checked out. Look for the difference in rpm drop between the left and right magnetos. The operating manual will recommend a maximum allowable difference. Typical is about 50 rpm. It is possible for the rpm drop on each mag to be within limits but the difference between the mags to be excessive. The most common problem here is improper timing of one or both magnetos. Get it checked out. A very small difference between the mags is all right. How about in-flight problems? A rough-running engine could mean a number of things, so be sure to follow the published procedures. Just because you are running on both magnetos doesn't mean that the remaining mag will automatically compensate for a failure of its partner. If one magneto develops a timing problem it could seriously affect the engine's ability to run. It is important to switch to the L and R positions to see if the engine will run better on one mag than on both. Remember, the L and R positions of the mag switch each are shutting off one magneto. If the problem is a bad mag, the engine will run terribly when switched to one position and will run well in the other switch position. It is certainly all right to continue your flight on one magneto to an airport where repairs can be made. The remaining magneto is not working any harder than usual and doesn't even know that its partner has been switched off. Knowing your airplane is important for safety. Spend time with a flight instructor or a certificated mechanic to learn about the inner workings of your machine. Depois destas explicações teóricas apetece-me perguntar-te: “ – Já alguma vez viste o “cabo de massa”? “. Provavelmente ouviste falar muito deste condutor eléctrico. Provavelmente nunca tiveste oportunidade de ver o dito cabo ao vivo. Um problema de interligação entre as aulas teóricas e as práticas. Prevendo que talvez tenha sido isso que te aconteceu – a mim foi o que aconteceu – preparei-te algumas fotos com a gentil colaboração do Manuel Rufino, o nosso TMA no Aero Clube de Torres Vedras. Vista geral do espaço entre o motor e a parede de fogo Vejamos agora o paralelismo do esquema teórico atrás representado e os elementos reais do motor do avião. O cabo de massa dum magneto Mas sabes porque é que eu puxei este assunto – que mais parece a discussão dum tema teórico-prático - para uma página dedicada à Segurança Aeronáutica? Porque um dia, dentro dum hangar, estávamos verificando a compressão dos cilindros de um avião e ao rodar ligeiramente o hélice para verificar os manómetros diferenciais, o motor pegou. Felizmente, parou, de imediato. Para nossa sorte foi só um “raté” Dirás que nós nem cuidado tivemos em certificarmo-nos se o interruptor de magnetos estava na posição “OFF”. Sim, tivemos esse cuidado, o avião estava com calços e a mistura na posição “POBRE”. Felizmente o estremeção do hélice não atingiu ninguém. Foi só o susto. Afinal um susto derivado do facto do cabo de massa estar quebrado num ponto qualquer entre o magneto e o interruptor de magnetos. Uma situação que pode acontecer e não ser detectável com facilidade visto o “cabo de massa” ser um cabo coaxial cujo trajecto é, em boa parte, entre a parede de fogo e a parte de trás do painel do avião. Locais, normalmente, não visíveis. Agora, tu, quando fazes o “check” de magnetos podes e deves detectar se há uma avaria no “cabo de massa”. Estás avisado! 4 PERFORMANCE Volta e meia faço uma revisão de conhecimentos há muito aprendidos. Acho que é importante para não termos lacunas que podem ser perigosas. Quando faço estas revisões tento sempre relacioná-las com factos passados na minha actividade de piloto. Porque é que durante o Campeonato do Mundo de Rally Aéreo, na África do Sul, descolei sempre com a mistura empobrecida? Porque é que uma vez não consegui subir a mais de 4.500’ espiralando sobre a veiga de Chaves? Porque é que durante um Campeonato Nacional de Espanha de Rally Aéreo, disputado na região de Alicante, preferi ser penalizado a tentar subir um dos fabulosos montes existentes na região? Efectivamente todas estas situações resultaram de eu ter resolvido correctamente e no momento problemas de “Performance”. Contudo, às vezes os pilotos nem sempre tomam as melhores decisões. Acontece a todos. No relato seguinte, o acidente registou-se numa situação verdadeiramente extrema. Vejamos os erros e aprendamos com eles. Isto para que a morte dos nossos companheiros pilotos não tenha sido em vão. DON'T FIGHT THE CHARTS On paper, this flight was a bad idea Wally Miller Do you calculate your airplane's takeoff, climb, cruise, and landing performance before each flight? What could happen if you don't? The outcome of a flight could vary from surprising-you used more runway than usual after landing 10 kt faster than the recommended speed on final--to disastrous. Consider this report from the National Transportation Safety Board. Shortly before 1 p.m. on October 23, 1999, a Cessna 172R with three persons aboard departed the Pitkin County airport in Aspen, Colorado (the accident report states that field elevation is 7,815 feet above mean sea level [msl]; other publications specify 7,820). After takeoff, the aircraft climbed eastward straight up the valley toward Independence Pass. Minutes later, a hiker saw the aircraft crash 1.5 miles short of the crest of Independence Pass "flying slowly, in a climb, with a nose-high attitude." The pilot died, and two passengers--both certificated pilots--were seriously injured. The three pilots had a cumulative 445 flight hours, mostly in Cessna 172s. The temperature at Aspen was 62 degrees Fahrenheit, 20 degrees above "standard." Elevation of the crash site was 11,948 feet msl. The crest of the pass was at 12,095 feet msl, and the density altitude at Independence Pass was 14,100 feet msl. Under standard conditions, performance charts showed that it should have taken the aircraft 26 miles to clear the elevation of the pass. But the conditions were not standard. The NTSB accident report stated that, under prevailing conditions (20 degrees hotter than standard), aircraft performance charts required a climb distance of 28.6 miles for the aircraft to have cleared Independence Pass. The crash site, however, was only 19 miles east of the Aspen airport, 9.6 miles short of the distance required to clear terrain. The NTSB listed the probable cause as "the pilot's improper decision to fly directly up the center of the valley and not to circle to gain sufficient terrain clearance altitude...[and] improper route performance planning by the pilot." But this article isn't about flying in the mountains. It isn't about blame, either. It's about what we might be able to learn and how we can try to prevent performance-related accidents from happening to us. It is not known whether the pilot had computed climb performance before takeoff or whether some unknown factor played a part in the aircraft's failure to clear Independence Pass. One thing we do know is that climb data for the 172R is based on flaps fully retracted. At the instant of impact, wing flaps were deployed 20 degrees. What we can learn from performance charts The Aspen crash and other performance-related accidents can help us think through, understand, and avoid the mistakes of other pilots. There are at least four lessons every pilot can learn from the Aspen accident: • Pilots need to acquire a preflight "feel" for the performance of their aircraft under current and forecast circumstances--and then make the time to check out marginal situations. • Marginal en-route conditions (like rate of climb, in the Aspen accident) need to be constantly assessed in flight, and immediate corrective or preventive action must be taken in the event abnormal, unexpected, or adverse conditions occur. • As a general practice, information obtained directly from performance charts should be used to assess aircraft capability on every flight before every flight. • Regular review of performance charts and related performance data can improve overall awareness in all aspects of flying. Most pilots are generally familiar with the performance of the aircraft they fly, but too few of us actually compute "performance" from the charts, except on cross-country flights. Even then, how many routinely compute climb performance--which proved to be a critical factor in the Aspen mishap? Or takeoff distance--except when conditions seem unusual, the runway is a little shorter than what we're used to, or the aircraft is at or near the maximum gross weight? Or landing distance? Having admitted that, what else might most of us not compute from the charts that we probably should? Noteworthy performance notes As the old saying goes, "The devil is in the details." In performance charts, those details appear among the notes printed on the charts themselves. It pays to fly the airplane by the book, too. I always figured that someone smarter than I am (like the manufacturer) designed and built it, and that the test pilots burned a lot of fuel to test it and record how the airplane needs to be flown. We need to pay attention and do what the book says. Though nobody knows how long the Aspen pilot's flaps had been set at 20 degrees, climb performance in the pilot's operating handbook (POH) for the Cessna 172R is based on having the flaps up. So is climb performance for the older Cessna 172N, which has a climb chart with that same note--flaps up--plus three other conditions and four additional notes, all of which specify other parameters pilots must follow to achieve the climb performance shown on that page. If they aren't met, the information on the chart is invalid. In another example, there are two charts for computing short-field takeoff performance in the Cirrus SR20; seven separate conditions are specified on those charts for the computed data to be valid. In the POH, these two charts are accompanied by an additional page containing a sample performance problem and further explanations that should be followed. Samples of "notes" in the fine print from performance sections of various general aviation POHs are listed below, grouped by the phase of flight to which they apply. Check out the flight manual or POH for the airplane you fly. Performance guidance varies considerably from manufacturer to manufacturer and from model to model. A review of 15 separate POHs revealed performance sections ranging from 13 to 32 pages. Paraphrasing of manufacturers' performance charts, plus computational tips, notes from performance pages, FAA guidance, and other authoritative information are summarized below, by phase of flight. General "performance" • Load your airplane properly (both weight and balance); improper loading can seriously affect performance. • Use the performance charts; don't extrapolate beyond them. • Charts are corrected to "standard day conditions" and do not address varying degrees of aircraft mechanical deterioration or pilot proficiency. • The effects of wind should be considered for climb, cruise, descent, and landing. • Be conservative in all computations; don't "live on the edge." • Existing and forecast conditions at departure, en-route, and destinations should be obtained before performance planning is begun; use actual landing weight for landing computations. • Understand and use whichever temperature scale your book demands: Fahrenheit or Celsius. • Make sure you're using the right speeds: KIAS or mph (especially if you fly more than one airplane, it can make a significant difference); calibrated versus indicated makes a difference as well. Takeoff, ground roll, obstacle clearance • Ensure proper tire inflation. • Lean the engine properly on runup, climb, and cruise--there is a significant power impact. • Use correct takeoff temperature (ATIS is not ambient; many manuals specify ambient); density altitude versus pressure altitude for various manuals. • Prescribed flap settings for normal and short-field landings vary, even within brands; check the charts. • Use the correct performance chart (i.e., short field versus normal takeoff). • Note specific obstruction, liftoff, and rotation speeds (some are specified). • Investigate runway slope and the general airfield environment (see "Accident Analysis: It's What You Know," October 2005 AOPA Flight Training). • Disregard takeoff headwind in computations--what if you count on it and it stops? Do not take off in tailwind; depending on your liftoff speed, departure in a 10-knot tailwind could increase your takeoff distance by 21 to 56 percent. • Observe performance chart limits; some charts stop at 8,000 feet. Don't extrapolate. • Hold brakes, check full throttle...then release brakes. • Most speeds are based on zero instrument error (but most instruments have errors; some are very significant in the area of stall speed). • One manual notes that dry grass will increase ground run by 15 percent over book value. Climb (rate, distance, time) • Are wheel fairings attached or removed? Performance effects vary; use proper corrections. • One general aviation manual says to increase climb time, fuel, and distance by 10 percent for every 10 degrees Celsius above standard temperature. • Corrections for cruise altitude and departure altitude temperatures (called temperature departure) should be applied to climb computations. • Proper gross weight. Cruise • Compute and apply cruise-altitude temperature deviation from standard temperature. • Note specific cruise parameters: 55-percent power, 65 percent, 75 percent, etc., and specific performance chart notes. • Note limits on charts and don't extrapolate. • Check correct settings for best power, best cruise, economy cruise, best endurance, prescribed leaning, EGT (peak or 50 degrees from peak, etc.). • One handbook says, "Reduce range 7 percent if wheel fairings not installed." • Another handbook: outside air temperature noted in Celsius, EGT noted in Fahrenheit; which is yours? • One manual differentiates between "endurance best economy" and "endurance best power." Landing performances Many of these points are in documents other than the performance charts. • " Options are important; read the fine print on every chart--one manual specifies data valid only for "standard wheels, tires, and brakes. Power off, 40 degrees flaps, paved level dry runway, full-stall touchdown, max braking." It also has separate data for "heavy duty landing gear." What does your POH say? Flight manuals and handbooks seldom mention grass, soft runways, hydroplaning, and other factors that have effect, though some comments are listed below; they won't be found in most manufacturer materials, though one manufacturer says, "add 15 percent for dry grass." Some comments from the FAA's On Landing pamphlets are: • If the runway is wet, airplane braking might be ineffective because of hydroplaning-sliding on the water. • "Book" landing data was derived from perfect technique by factory test pilots under ideal conditions. Most computations are based on touchdown at 1.1 times stall speed. If you touch down even 10 percent above that, your landing roll will be over 20 percent longer than "book." • Flying "final approach" airspeed into the flare (rather than slowing to 1.3 times the stall speed as recommended in most manuals) nearly doubles your landing distance; if you're carrying extra airspeed for gusts (as you should), understand that it will cost you even more landing distance to dissipate it. Developing a "feel" for these book values can be priceless when faced with marginal situations. • Handbooks generally use either a specific speed (usually 1.3 times stall speed) based on gross weight or a specific recommended speed on final approach. The small print might or might not specify other speeds. Check it out. Take care how you manage all of them. • Many pilots use the "bottom of the white arc" to determine stall speed when, in actuality, that is stall speed with flaps down at maximum gross weight--if your flaps aren't fully down or the aircraft is loaded to less than max gross weight, this will not be your stall speed. • Even 200 to 300 pounds in a general aviation airplane can make a difference in your "float" and cost you precious runway space. • Landing in a 10-kt tailwind--and touching down 10 kt fast--will almost double your landing distance; do you have enough runway? Don't land downwind unless you know you can afford it. In the case of the Aspen accident, pausing to do more detailed performance analysis or climbing to altitude before proceeding on course probably would have prevented the accident. But it all would have had to start with awareness that there might be a problem because of the environment or the nonstandard temperature--awareness and concern over aircraft climb performance, or the lack of it. Perhaps the pilot was aware, but the press of time could have been perceived as a bigger problem. Whether it's mountains, rising terrain or trees off the end of the runway, temperature, or weather--or whatever else--the message is still the same: When in doubt, check it out. Depois de leres este relato permite-me que te lembre que fazer um voo não é só “dar à chave e vamos embora”. Um pouco de planeamento faz bem e é bonito. E já agora não te esqueças duma coisa: as informações sobre performance do avião, fornecidas pelo fabricante, foram obtidas a partir de aviões num estado de afinação óptima, nas melhores condições estruturais possíveis e voados por pilotos de ensaio da fábrica. Situações totalmente inverdadeiras nos teus voos. Afinal o teu avião tem uma afinação assim-assim, estruturalmente já tem uns empenozitos derivados aos quase trinta anos de voo e, sem querer ofender-te, as tuas performances como piloto estão um bocadinho afastadas das dos pilotos de ensaio da fábrica. Nota bem que eu disse só um bocadinho! Tu és um pilotaço! No relato do acidente, o articulista – Wally Miller – refere que “...At the instant of impact, wing flaps were deployed 20 degrees ...”. Como o piloto faleceu no acidente, provavelmente, nunca se poderá saber porque é que ele “sujou” o perfil. Será que ele o fez porque tentou uma aterragem de emergência e pretendia fazê-lo à menor velocidade possível para minimizar os efeitos do impacto ou será que ele não pretendeu aterrar de emergência e, ignomínia das ignomínias, foi atrás da expressão “hiper-sustentador” pela qual se costuma designar os diversos dispositivos entre os quais se incluem os flaps de bordo de fuga? Se a razão para “sujar” o perfil foi a primeira, fê-la correctamente. Se a razão foi a segunda, pagou com a vida a sua hiper-ignorância em matéria de Aerodinâmica e Performance. Ou será que ele foi levado para a segunda razão pela utilização de um dos mais infelizes “jargões” – hiper-sustentador - utilizados na gíria aeronáutica?4 Deixa-me terminar recomendando-te que te associes à AOPA Portugal. Perguntarás, de imediato, como o poderás fazer. Visita o site da AOPA Portugal em www.aopa.pt e manda as tuas perguntas para o Presidente da AOPA Portugal através do seguinte e-mail address: [email protected]. Gostaria de contar com a tua presença na nossa AOPA. 4 Um abração do Fernando

Download