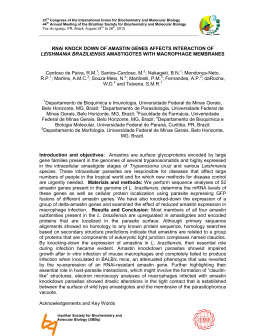

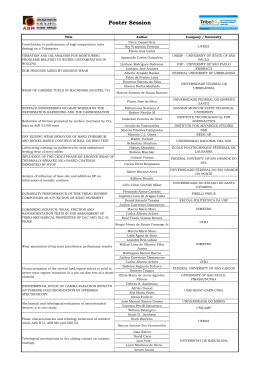

Massic wear evaluation by ball wear test using 3D profilometry P.S.Souza1, R.Alecrim1, N.A.Murilo2, C.W.M.Silva3, J.R.G.Carneiro2, J.R.T.Branco1 1 Fundação Centro Tecnológico de Minas Gerais, Belo Horizonte, SDT, MG, Brazil 2 Pontificia Universidade Católica de Minas Gerais, Belo Horizonte, MG, Brazil 3 Rede Temática em Engenharia de Materiais, Ouro Preto, MG, Brazil. The micro abrasive wear test with sphere fixed (CALOTESTE) evaluates the resistance to the wear at coatings or substrate. In the test, a ball is rotated whilst being pressed against the sample and an abrasive slurry is fed into the contact zone. A spherical depression is produced and the size of this depression is measured. Where perforation of the coating has not occurred, the wear rate of the coating can be obtained from a single crater. When perforation of the coating occurs, by making a series of these craters and measuring the size of the scar dimensions, the wear coefficient of both the substrate can be calculated by the Archard equation: K=V/N.S (mm³/N.m). Where S is the sliding distance (m), N is the normal load used (N) and V is the worn volume (mm³). According to standard prENV 1071-2, this value of volume V can be estimated mathematically using the equation V=π.d4/64.r, where d is the diameter of the wear scar (measured by optical observation) and r is the radius of the sphere. This work investigated the error associated with this theoretical formulation for calculating the worn volume, comparing calculated values with values obtained by 3D profilometry technique, Pic.1, and also it observed the impact of the final value of the coefficient of abrasive wear. This work were tested coating of ABNT 420 steel deposited on ABNT 1045 steel substrate, by thermal spraying, where perforation of the coating has not occurred. 8,00E-03 Volume(mm³) 7,00E-03 6,00E-03 5,00E-03 Profilometry 4,00E-03 Optical Observation 3,00E-03 2,00E-03 1,00E-03 0,00E+00 0 2 4 6 8 10 12 14 Samples Pic.1- 3D Profilometry of a volume worn (steel 420) Pic.2- Volume’s graph worn samples of steel coated 420 Wear volume values indicate similarly between the results obtained by profilometry and according to standard, this to most studied events, Pic.2. Thus, the impact of approximation error in the mathematical calculation of the micro abrasive wear coefficient is negligible. Keyword: micro abrasive wear coefficient, wear mass -3D profilometry. Work supported by FAPEMIG – Fundação de Amparo a Pesquisa do Estado de Minas Gerais. [1] - EUROPEAN COMMITTEE FOR STANDARDIZATION, prENV prENV 1071-2:2001 and 1071-6:2001. Advanced technical ceramics - Methods of test for ceramic coatings - Part 6: Determination of the abrasion resistance of coatings by the microabrasioned wear test, (2001). [email protected], [email protected] – Tribology Lab, SDT, CETEC – 2000, José Cândido da Silveira Avenue, Horto, Belo Horizonte, MG, Brazil.

Baixar