i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y x x x ( 2 0 1 0 ) 1 e1 1 Available online at www.sciencedirect.com journal homepage: www.elsevier.com/locate/he Review Overview of hydrogen production technologies from biogas and the applications in fuel cells Helton José Alves a,*, Cı́cero Bley Junior c, Rafael Rick Niklevicz c, Elisandro Pires Frigo b, Michelle Sato Frigo b, Carlos Henrique Coimbra-Araújo a a Biofuels Technology Course, Federal University of Paraná (UFPR-Campus Palotina), R. Pioneiro, 2153, Jardim Dallas, 85950-000 Palotina, PR, Brazil b Agronomy Course, Federal University of Paraná (UFPR-Campus Palotina), R. Pioneiro, 2153, Jardim Dallas, 85950-000 Palotina, PR, Brazil c International Renewable Energy Center-Emphasis on Biogas (CIER-Biogas), ITAIPU Binacional-Parque Tecnológico Itaipu (PTI), Av. Tancredo Neves, 6731, 85867-900 Foz do Iguaçu, PR, Brazil article info abstract Article history: Traditionally, H2 is a large-scale production by the reforming process of light hydrocarbons, Received 13 December 2012 mainly natural gas, used by the chemical industry. However, the reforming technologies Received in revised form currently used encounter numerous technical/scientific challenges, which depend on the 7 February 2013 quality of raw materials, the conversion efficiency and security needs for the integration of Accepted 13 February 2013 H2 production, purification and use, among others. Biogas is a high-potential versatile raw Available online xxx material for reforming processes, which can be used as an alternative CH4 source. The Keywords: house gas emissions. Within this context, the integration of biogas reforming processes Biogas and the activation of fuel cell using H2 represent an important route for generating clean Reforming processes energy, with added high-energy efficiency. This work expounds a literature review of the Hydrogen biogas reforming technologies, emphasizing the types of fuel cells available, the advan- Fuel cells tages offered by each route and the main problems faced. production of H2 from renewable sources, such as biogas, helps to largely reduce green- Copyright ª 2013, Hydrogen Energy Publications, LLC. Published by Elsevier Ltd. All rights reserved. 1. Introduction Biogas is a product composed mainly of methane (CH4) and carbon dioxide (CO2), associated with traces of other gases such as hydrogen sulfide (H2S), ammonia (NH3), hydrogen (H2), nitrogen (N2), oxygen (O2) and vapor water (H2O). Table 1 shows the typical chemical composition of biogas [1e3]. This mixture of gases is the result of the anaerobic digestion process of the residual biomass from various sources (animal waste, sewage treatment plants or industrial wastewater, landfills, etc.), which is performed by microorganisms that decompose organic matter in nature or in equipment/devices known as biodigester tanks [4e6]. H2S is an undesirable component in biogas, since it is a corrosive gas capable of damaging the equipment and accessories used in the process to obtain energy. CO2 and humidity can also be considered as impurities because they reduce the calorific value of biogas in direct combustion for thermal power generation [7,8]. Of the many variables that can automatically change the chemical composition of biogas * Corresponding author. Tel.: þ55 44 32118595; fax: þ55 44 32118548. E-mail addresses: [email protected], [email protected] (H.J. Alves). 0360-3199/$ e see front matter Copyright ª 2013, Hydrogen Energy Publications, LLC. Published by Elsevier Ltd. All rights reserved. http://dx.doi.org/10.1016/j.ijhydene.2013.02.057 Please cite this article in press as: Alves HJ, et al., Overview of hydrogen production technologies from biogas and the applications in fuel cells, International Journal of Hydrogen Energy (2010), http://dx.doi.org/10.1016/j.ijhydene.2013.02.057 2 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y x x x ( 2 0 1 0 ) 1 e1 1 Table 1 e Chemical composition of biogas [1e3]. Composite CH4 CO2 H2S NH3 H2 N2 O2 H2O Percentage 55e70 (vol%) 30e45 (vol%) 500e4000 (ppm) 100e800 (ppm) <1 (vol%) <1 (vol%) <1 (vol%) <1 (vol%) and its energy content, the origin and quality of the biomass used, the type of biodigester and the management used in the anaerobic digestion process should be mentioned [9,10]. The use of biogas is quite versatile since: i) its chemical energy can be converted into mechanical energy by controlled combustion processes in stationary engines, which then put in motion the generators to promote a direct conversion into electrical energy; ii) it can be used to co-generate thermal energy, generating hot water and steam with the engine’s high temperatures; iii) it can be burned to generate heat energy in boilers; iv) it can be applied as fuel to automotive and stationary engines [11e16]. Although there are various types of applications, new biogas alternatives need to be strategically exploited to consolidate their power generation potential and significance. A promising possibility is to obtain H2 from biogas for its use in loading fuel cells [17e20], as proposed in the work presented herein. H2 has high energy capacity, with the largest amount of energy per mass unit than any other known substance (121.000 kJ/kg). The best energy use of H2 takes place in fuel cells. Fuel cells achieved remarkable progress in the last decade, which were developed for transportation, as well as for power generation in stationary or portable installations. The fuel cell system can include several applications, such as: large power stations; power distribution generators, used in buildings and homes; small portable power supply equipment for microelectronic devices; and auxiliary power units in vehicles, among others [19,21,22]. These cells then transform the chemical energy of the H2 molecules into electrical energy with up to 60% of efficiency [19,21]. Additionally, when H2 is used in vehicular fuel cells, it can yield two to three times more efficiency than the current devices used in internal combustion vehicles (20e30%). These qualities make H2 one of the main alternatives for replacing fossil fuels consumed worldwide [22]. Currently, H2 is widely used as raw material in the chemical industry, in food processing, in hydrogenation processes, in the production of ammonia and methanol, in the FischereTropsch synthesis, in the pharmaceutical industry, among others [23]. The demand for H2 grows yearly. The available 2008 data indicate that H2 consumption by the oil sector was of 364 billions/m3, while the global H2 consumption was of 409 billions/m3. It is also estimated that by 2013 the global H2 demand will increase 18%, with nearly half of this expected increase generated outside the refineries by other sectors [7]. In the pursuit to reduce greenhouse gases and to remove carbon from the industrial processes, the projected H2 supply for outside the refineries is a strategic target, which will facilitate the entrance of “reforming” technologies from renewable resources in the H2 market [17,19]. The main techniques used to obtain large-scale H2 promote the reforming of light hydrocarbons, especially methane, a major biogas component [24]. However, several of these routes produce CO mixed with H2, characterizing the socalled “synthesis gas”, widely used in industries [25]. Attaining high purity H2 from the synthesis gas is a relatively expensive process, since CO has to be removed [26]. In many studies that address the reforming processes, there is a research emphasis on catalysts to lower the costs and the energy involved. The development and use of catalysts, which have high catalytic activity and stability in the reforming processes, can ensure reducing the high temperatures normally used, accompanied by increased reaction speeds as well as slowing down the catalyst deactivation process by poisoning (chemisorption of sulfur and/or other impurities) or carbon deposition (coke), which are the main problems usually encountered [27e33]. The objective of this paper is to present a concise look at the possibilities of using biogas as renewable raw material for the production of H2 to activate fuel cells. 2. Processes used for generating hydrogen from methane and biogas The most common methane reforming processes for hydrogen production are known as: “steam reforming (SR)” [34e43], “partial oxidation reforming (POR)” [44e51], “autothermal reforming (ATR)” [52e57], “dry reforming (DR)” [58e63] and “dry oxidation reforming (DOR)” [1,64e67]. There are other non-conventional processes reported in the literature for the production of H2 from methane, such as: “solar reforming” [6,24], “thermal plasma reforming” [68e71] and “catalytic decomposition” [72,73]. Traditional methods of large scale H2 production used by industries are the first three mentioned, with natural gas as the main source of hydrocarbons (z90% of CH4). In most studies found in the literature on biogas reforming to produce H2, there are detailed experiments using mixtures of CH4 and CO to simulate laboratory biofuel compositions. However, the high purity CH4 (>99%) is commonly used to simulate laboratory scale reforming processes, with few studies found that use biogas from the direct digestion process of residual biomass (real biogas) in their experiments [5,74,75]. Thus, to choose the reforming process using biogas, its composition must be taken into account in three different situations, which may be sequential: i) in natura, with 55e70% of CH4, 30e45% of CO2 and 500e4000 ppm of H2S (Table 1); ii) partially treated for H2S removal; iii) purified for “biomethane” enrichment (93e96% of CH4, 4e7% of CO2 and <20 ppm of H2S). Note that in the latter case, the CH4 content is hardly ever higher than 95% using economically viable treatments [1e3,7,8]. Please cite this article in press as: Alves HJ, et al., Overview of hydrogen production technologies from biogas and the applications in fuel cells, International Journal of Hydrogen Energy (2010), http://dx.doi.org/10.1016/j.ijhydene.2013.02.057 3 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y x x x ( 2 0 1 0 ) 1 e1 1 Before reforming, the methods tipically used for the removal of corrosive species in biogas can be divided into two categories: i) those that involve physico-chemical phenomena (including the processes of absorption in aqueous solutions; chemical adsorption of H2S on solid adsorbents such as activated carbon, modified zeolites and metal surfaces, with consequent formation of metal sulfide, and washing with solvents), and ii) those involving biological processes (consumption of contaminants by living organisms, such as species of chemothrophic thiobacteria, which serve as oxidants in the sulfur biofilters, biotrickling filter and units of biodepuration, and conversion to less harmful forms) [24,76]. In general, H2 can be produced by methane or biogas reforming in a wide temperature range of 600e1000 C (endothermic and reversible reactions), involving predominantly catalytic processes that are often combined. Both reforming processes can be performed under low pressure (in most cases under atmospheric pressure) in tubular fixed-bed or fluidized reactors [7,24,25]. The reforming processes in the next items use methane as raw material, since it is the main source of hydrocarbons used. However, in various reforming processes, biogas can be used as a methane source, which directly depends on its composition. Thus, most of the research involving methane reforming can also be adapted to biogas reforming. Table 2 shows the chemical reactions cited and their respective thermal reactions at 298 K (25 C), in order to facilitate the information organization contained throughout the work. 2.1. Conventional reforming processes 2.1.1. Steam reforming (SR) SR is the combination of methane with water vapor in the presence of a catalyst, producing CO and H2 (Eq. 1). This is a highly endothermic process which requires reaction temperatures ranging between 650 and 850 C, to obtain H2 yields of 60e70% [34e43]. Although it has great energy expenditure SR is the most widespread industrial route to obtain H2. The H2/CO ratio produced in SR is equal to three, the most appropriate one from the H2 generation point of view. In order to eliminate CO, the WatereGas Shift reaction, commonly known as “Shift reaction” (Eq. 2), is the most widely used, requiring temperatures ranging from 300 to 450 C and catalysts based on Fe, Cu, Mo or FeePd alloys (among others), which enables the production of an additional amount of H2. Equation 3 shows the reaction of methane SR associated with the shift reaction [2,3]. Additionally, the harsh conditions required promote parallel carbon formation reactions (methane decomposition reaction), Boudouard reaction or disproportionation reduction reaction of CO, respectively, Eqs. 4, 5 and 6) favoring catalyst deactivation by carbon deposition on its surface (coke) [77e79]. It is usually desired for the carbon to be on the catalyst surface in the form of nanotubes, which causes lower carbon dispersion over the surface, thus preserving its activity for a longer period of time [72]. The catalysts usually used in SR consist of Ni (transition metal), Pt, Rh or Pd (noble metals), of which the Ni catalysts have the advantage of having lower costs. On the other hand, Ni has greater deactivation susceptibility by the coke formation due to the high temperatures used, which makes the Pt and Pd catalysts interesting with regards to stability. When there is limited mass transfer, Rh is used as it has catalytic activity that is much higher than Ni and a lower coke formation tendency [36,42]. Basic supports containing promoter elements such as Ca, Mg and K can also be used to decrease carbon accumulation on the catalyst, since they favor carbon species gasification by the carbonewater steam reaction (reverse Eq. 6), due to increased water adsorption [80e83]. The metals cited, as well as others, can be used as active species in the preparation of supported catalysts using various types of matrices, such as: SiO2, Al2O3, ZrO2, etc. [27,41]. To obtain high purity H2, the CO2 and CO formed in SR must be effectively separated, which is not unique to this type of reforming, required in all the processes where there is greater interest in H2 production rather than synthesis gas. Typically, the H2 production applying the conventional SR process uses three integrated systems: reformer, conversion reactor (shift reaction) and separating unit [84]. Several studies show good efficiency in the separation process using selective membrane reactors with H2, which can be directly fed to the fuel cell. The membrane reactor then allows all reactions developed in the conventional reactor to occur on a single device, producing pure H2. Thus, the SR methane reaction (Eq. 1) and shift reaction (Eq. 2) occur simultaneously within the reactor that contains a nickel Table 2 e Chemical reactions involved in the methane reforming processes [7,24,79,81]. Identification of reaction Eq. Eq. Eq. Eq. Eq. Eq. Eq. Eq. Eq. Eq. Eq. 1 2 3 4 5 6 7 8 9 10 11 Type of reaction Thermal reaction, DH298 (kJ/mol) CH4 þ H2O4 CO þ 3H2 CO þ H2O4CO2 þ H2 CH4 þ 2H2O4CO2 þ 4H2 CH44C þ 2H2 2CO4C þ CO2 CO þ H24C þ H2O CH4 þ 1/2O24CO þ 2H2 CH4 þ 2O24CO2 þ 2H2O CH4 þ 1/2xO2 þ yCO2 þ (1xy)H2O4(y þ 1)CO þ (3xy)H2 CH4 þ CO242CO þ 2H2 CH4 þ bCO2 þ (1 b)/2O24(1 þ b)CO þ 2H2 206 41.2 165 74.9 172.4 131.3 35.6 801.7 z0 247.4 (285b 38) 0 b 1 Please cite this article in press as: Alves HJ, et al., Overview of hydrogen production technologies from biogas and the applications in fuel cells, International Journal of Hydrogen Energy (2010), http://dx.doi.org/10.1016/j.ijhydene.2013.02.057 4 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y x x x ( 2 0 1 0 ) 1 e1 1 catalyst bed. Furthermore, the membrane provides greater shift ability to the chemical equilibrium of the reaction, increasing the productivity of H2, since removing H2 from the reaction medium displaces the dynamic equilibrium for forming products. This shift allows the reforming reaction to be carried out at temperatures below 500 C, without any methane conversion loss [38,42,85e87]. 2.1.2. Partial oxidation reforming (POR) POR is an alternative method to produce H2 with reduced energy costs, since the reaction is moderately exothermic (Eq. 7), contrary to SR which is highly endothermic. In this type of reaction, methane is partially oxidized to CO and H2 (synthesis gas), at atmospheric pressure, requiring temperatures between 700 and 900 C to ensure complete conversion (H2/CO ratio close to 2) and to reduce soot formation. However, a slight decrease in CO selectivity cause the methane to react with oxygen to form CO2 (Eq. 8), leading to complete combustion (strong exothermic reaction), which results in high reaction temperature increase, which can form hot-spots in the reactor bed and form coke on the catalyst surface [48e51]. According to ÁVILA-NETO (2009) [88], although the temperature increase favors the CH4 conversion, the O2/CH4 feed ratio applied to the reactor is the variable that most influences the conversion. In this case, CH4 is completely consumed to the O2/CH4 ratio close to 0.5. Some studies focus on developing high activity and stability catalysts for methane POR. Mixed metal oxides, solid solutions of NiOeMgO, NieMgeCreLaeO and CaeSreTieNi are reported as highly active and selective catalysts at elevated temperatures (>800 C), with higher carbon deposition resistance [48,89]. 2.1.3. Autothermal reforming (ATR) Because it is a highly endothermic, SR associated with the Shift reaction (Eq. 3) requires external power supply. A reactor’s internal heating is generally more efficient than external heating, and a reaction that releases energy in the catalyst bed can make the manufacturing process of H2 energetically more economical. However, the partial oxidation reaction of CH4 has the advantage of being exothermic (Equation 7), but generates a lower H2/CO ratio in comparison with SR. Based on these observations, other CH4 reforming types, called ATR, can be performed with a combination of the two aforementioned reforming techniques, resulting in the sum of reactions described by equations 3, 7 and 8 [53e57]. ATR also occurs in the presence of CO2, represented by Equation 9 [74,75]. There is a thermal zone in the reactor, where the partial oxidation is conducted to generate the heat required for SR that takes place in the catalytic zone, fed by a downward steam flow. The heat generated by the zone where the partial oxidation takes place does not require external heating, resulting in an efficient energy process. The advantages of ATR concern the speed with which the reactor can be stopped and restarted, and the capacity to produce higher amounts of H2 with lower O2 consumption when compared to isolated POR, since the H2/CO ratio in the synthesis gas produced can be easily adapted through the CH4/O2/H2O ratio to feed the reactor, leading to the synthesis of the desired product. Additionally, the combination of these reactions can improves the temperature control in the reactor and reduce the formation of hot-spots, thus avoiding the deactivation of the catalyst [54,90]. In this system the partial oxidation reaction of methane occurs simultaneously with SR, which makes the process selfsustaining, significantly reducing energy costs. Thus, for SR methane to be advantageous over others, it is necessary that it takes place under autothermal conditions, performed adiabatically together with partial oxidation reaction, in order to produce synthesis gas with a H2/CO ratio between 2.0 and 3.5, using H2O/CH4 ratios between 1.0 and 2.5, O2/CH4 between 0.25 and 0.55 [52e54,56]. It should be noted that the selectivity of products in the oxidation zone is highly dependent on temperature, that is, partial oxidation reactions (Eq. 7) are favored by increased temperature, and total oxidation (Eq. 8) favored by decreased temperature [91]. 2.1.4. Dry reforming (DR) DR occurs when CH4 reacts with CO2 to produce CO and H2 (Eq. 10). This type of reaction is attractive from an environmental standpoint, since it consumes two gases that contribute to the greenhouse effect (CH4 and CO2). However, it should be noted that the endothermic nature of the reaction minimizes the reduction of CO2 emissions, since the CO2 emitted by the burning of fuel used to generate the heat required for the reaction should be accounted for. From the industrial point of view, methane DR also satisfies the requirement of many synthesis processes of oxygenated compounds and liquid hydrocarbons (FischereTropsch synthesis), which is an efficient route for producing synthesis gas, yielding a H2/CO ratio close to 1 [59,63,79,80]. According to the literature regarding this topic, the main reaction (Eq. 10) can be accompanied by competing parallel reactions that modify the equilibrium conversion of CO2 in CH4, as follows: reverse gasewater shift (Eq. 2 reverse), decomposition of carbon monoxide (Boudouard reaction) (Eq. 5) and decomposition of methane (Eq. 4) [60]. In general, DR occurs at temperatures ranging between 700 and 900 C, using a CH4/CO2 molar ratio between 1 and 1.5, attaining H2 yields of around 50% [62,63,92]. If the decomposition reaction of the methane (Eq. 4) is faster than the carbon removal rate, there will be serious problems for the formation of coke, with the consequent deactivation of the catalyst and blocking of the reactor by the coke formed. The decomposition reaction of carbon monoxide (Eq. 5) is favored at low temperatures and, together with the decomposition reaction of methane, it can generate carbon [93e97]. Thus, the main problem of DR is the greater tendency to form coke, accumulated on the support as well as on the active phase of the catalyst, since the carbon-water steam reaction does not occur as it does in SR (reverse Eq. 6). Much effort has been employed in the search for catalysts that avoid the deposition of carbon, while being thermally stable, maintaining selectivity in the production of H2 [31,63,97,98]. The most active catalysts for methane DR, reported in literature, are those that use metals of the groups 8, 9 and 10 of the Periodic Table, particularly Rh, Ru and Pt. However, these Please cite this article in press as: Alves HJ, et al., Overview of hydrogen production technologies from biogas and the applications in fuel cells, International Journal of Hydrogen Energy (2010), http://dx.doi.org/10.1016/j.ijhydene.2013.02.057 5 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y x x x ( 2 0 1 0 ) 1 e1 1 metals are expensive and of limited availability, and are therefore, in practice, not suitable for the process at an industrial level. Therefore, various catalysts have been developed according to greater availability and lower price, which is usually associated with increased coke susceptibility, as in the case of Ni and Co catalysts [60,61,99e102]. 2.1.5. Dry oxidation reforming (DOR) A strategy for the control of carbon deposition on the surface of the catalysts is to combine the methane DR and POR. Cofeeding O2 with CH4 and CO2 provides additional advantages, such as: reducing the global energy involved, improving the conversion of CH4 and increasing the product yield at a lower temperature; enhanced catalyst stability and increased deactivation resistance; control the H2/CO ratio by modulation of O2 to meet the flow requirements [1,65]. Methane DOR can be written as shown in Equation 11, where b is the stoichiometric fraction of CO2 fed with traditional DR. It is evident that the theoretical H2/CO ratio, given by 2/(1 þ b), is greater in DOR for b < 1, than non-oxidative DR, where b ¼ 1 [67,79]. In methane DOR the product ratio of H2/CO and the exothermic or endothermic nature can be controlled by manipulating the process variables, particularly the reaction temperature and/or relative concentration of O2 in the reactor feeding. In general, the exothermic nature increases for a given temperature as the O2 concentration in the feed increases. This is due to the fact that the addition of O2 determines the oxidation process (complete oxidation when b ¼ 0 (Eq. 8), or traditional DR when b ¼ 1 (Eq. 10)), and automatically, the amount of heat released or consumed [66,67,79]. Considering that dry reforming in the presence of O2 simultaneously involves the traditional DR (Eq. 10) and POR (Eq. 7) processes, characterized as endothermic and exothermic, respectively, the methane conversion to synthesis gas occurs with high energy efficiency, requiring little external energy [103e108]. Research on catalysts for this type of reaction is usually directed to support development or the insertion of a second metal associated with Ni (bimetallic catalyst) to enhance its stability [1,47,64,65]. Regarding DR, the addition of O2 reduces the formation of coke on the catalyst due to greater control of the partial oxidation of the novel carbon species, CH4 and CO2, for CO [92]. Table 3 shows a summary of the reaction conditions used in the different H2 production routes using methane or real biogas as the main raw materials. 3. Use of hydrogen in fuel cells 3.1. Fuel cell concepts Fuel cells are devices that can convert the chemical energy of a fuel directly into electricity, without combustion, with high Table 3 e A summary of studies on H2 production using methane or biogas in conventional reforming processes. Process SR POR ATR DR DOR Reactor Temperature ( C) Catalyst H2/CO Conversion of CH4 (%) Reference Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fluidized-bed Fixed-bed Fixed-bed Fluidized-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fixed-bed Fluidized-bed Fixed-bed Fluidized-bed 600 650 700 715 850 750 750 750 800 850 700 800 700 800 700 750 750 850 800 750 860 750 700 700 750 900 850 750 Ni-Ce0.8Zr0.2O2 NiMg17.4Al1.6O20.8 Ni/Al2O3 Ru/Al2O3 Ni/Al2O3 Ni/CaOeAl2O3 Ni/Al2O3 Ni/Al2O3 Pt/CeO2 NiO/MgO Ni/Al2O3 NiCoMgCeOx/ZrO2eHfO2 Ni/MgAl2O4 Pt/ZrO2/Al2O3 Rh/Al2O3 Ni/Cu5Zr10Ce20Al65O8 Ni/cordierite Ni/insulating (Si,Mg,Al) (monolithic) Ni/SBA-15 Ni/NiOeMgO Ni/CeO2eAl2O3 Rh-NiLa/g-Al2O3 La/hydrotalcite Ni/CeZrO2eMgAl2O4 Rh-NiLa/g-Al2O3 Pt-Rh/CeeZrO2eAl2O3 NdCoO3 perovskite 5Ni/5ZrO2eSiO2 3.4 3.7 a 2.7 2.1 2.5 2.0 2.2 2.0 2.0 2.0 2.0 3.2 2.0 3.5 3.9 2.6 2.8 1.4 1.2 1.3 0.9 0.7 1.2 1.0 1.0 1.7 1.9 70 98 85 90 98 95 85 96 85 87 100 95 92 100 95 100 90 95 92 75 90 70 67 85 86 100 95 77 [41] [43] [39] [105] [2] [3] [106] [106] [44] [45] [46] [48] [52] [53] [55] [56] [74],b [75],b [31] [111] [60] [92] [62] [63] [92] [1] [66] [47] a Information not available. b Real biogas. Please cite this article in press as: Alves HJ, et al., Overview of hydrogen production technologies from biogas and the applications in fuel cells, International Journal of Hydrogen Energy (2010), http://dx.doi.org/10.1016/j.ijhydene.2013.02.057 6 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y x x x ( 2 0 1 0 ) 1 e1 1 efficiency and with lower polluting emissions than conventional equipment/techniques. The development of various types of fuel cells partially focuses on optimizing the layer of the catalytic electrodes, and specifically on reducing the amount of metal without appreciable loss of cell performance. It is known, however, that with the operation there may be significant changes in the structural properties of the catalyst, and then its stability assumes a significant role in the cell’s useful life [109e111]. In a fuel cell the power supply is uninterrupted while it is fed with the fuel and the oxidant, different from a battery in which the energy storage is limited by the amount of reagent stored in it. Insofar the theoretical thermodynamic efficiency of fuel cells are close to 90% in the thermal engines (Carnot), this efficiency is of only 40% under typical operating conditions for both systems. In practice, the efficiency of a fuel cell is usually less than 60% [112]. 3.2. Types of fuel cells Fuel cells have been developed to supply different markets. Owners of electric stations investigate the use of PAFC cells (Phosphoric acid fuel cell ), MCFC cells (Molten carbonate fuel cell ) and SOFC cells (Solid oxide fuel cell ). The latter cell promises high efficiency (50%e60%) and its market type is not restricted by the size or weight of the cell, hence requiring very durable systems. Similarly, residential cells represent a large and attractive market segment. However, for these purposes, as well as for automobile use, there is a size and weight limitation, requiring to evaluate the ability of intermittent operation, for the fuel cell PEMFC or PEM (Proton Exchange Membrane Fuel Cell ), which has an electrolyte polymeric membrane, the most widely studied [19,81,90,108,113]. According to CIPITÍ et al. (2008) [114], PEMFC, stands out as a key option, for transportation use (electric vehicles) as well as for smallscale power generation facilities (homes) due to durability, compatibility, low operating temperatures, high conversions and low polluting and noise emissions. The degree of H2 purification required for fuel cells depends on the application. Gas separation by pressure swing adsorption (USGAMP) or palladium membranes are used to produce H2 with purity above 99.999%. For fuel cells PEMFC or PAFC (low temperature) CO must be reduced to less than 10 ppm [19]. However, CO drastically affects the performance of the system, as it usually binds to the metal atoms of the catalyst, preventing adsorption and the consequent oxidation of H2. Thus, the choice of a catalyst electrode tolerant to CO and/or the use of tools to minimize the effects caused by the reaction contaminant (current pulses in the cell, air insertion with fuel flow, introduction of H2O2 into the cell anode, etc.) are some of the main challenges to be overcome regarding the low-temperature fuel cell technology [84,115e117]. It is known that at high temperatures the tolerance to CO increases significantly, enabling its use in some fuel cells, such as MCFC and SOFC (high temperatures), H2 with higher CO concentrations, expanding the possibilities of using an interconnected system for methane or biogas reforming processes [19]. In this case the use of bimetallic eletrodic catalysts that contain a second element besides Pt, such as Ru, Sn, Mo and Os, which form alloys or co-deposits dispersed on carbon, result in significant tolerance increase to CO [118e121]. The SOFC fuel cell is currently one of the most studied because of its exceptional application potential as a power generation system due to its high-energy conversion efficiency. Correspondingly, a considerable advantage of SOFC is the possibility of using other fuels in addition to H2 such as natural gas, biogas, gasoline, methanol and ethanol [19,81,108]. 3.3. Internal reforming of biogas in fuel cells While the technology to efficiently convert H2 into electrical energy and into the required power levels are closer to commercialization, parallel attempts have been made for the direct use of biogas in fuel cells, known as “internal reforming” [5,20,109,122e129]. High-temperature fuel cells, such as SOFC and MCFC, are better suited for the direct use of biogas, because they have a greater capacity to thermally integrate internal reforming and increase tolerance against contaminants of H2, while maintaining high electrical efficiency (close to 50%). Several studies have been reported in the literature on the use of various types of biogas internal reforming in high-temperature fuel cells. In some cases, it was demonstrated that, electricity can be stably obtained from biogas without auxiliary fuel, external reformer, humidifier, and precious metal catalyst [124,125,130]. Typically, SOFC cells exhibit eletrodic catalysts that comprise: i) anode and support: Ni-YSZ (yttria-stabilized zirconia) or NieScSZ (scandia-stabilized zirconia), ii) cathode: LSM (lanthanum strontium doped manganate) or composite and iii) electrolyte: YSZ-TiO2, ZEI-MgO, Y2O3, CeO2, MnOeCeO2 and GdO2eCeO2 [19,127,128]. A disadvantage of the internal reforming process is the formation of CO, which acts as a poison to the fuel cell when in the range of 50 ppm [81,126]. Additionally, the variability of biogas composition and the poisoning of the catalysts of the fuel cell by carbon deposition (coke) by CO disproportionation (Eq. 5) and the presence of sulfur traces, represent the main problems commonly faced [2]. In the former case, the coke formation reduces the catalyst activity and simultaneously blocks the pores and can destroy their structure. New approaches to reduce carbon deposition by adding different promoters (Sn, Mo, Li, Mg, Ca, Sr, Ce, Ru, Rh, Pd and Pt) in the anode Ni-YSZ (yttria stabilized zirconia) are reported in the literature. Furthermore, the addition of water and air for a CO2/CH4 ratio between 0 and 1, is considered a strategy to suppress carbon formation [128]. In the latter case, the sulfur-containing species cause a substantial decrease in the conversion to hydrogen. This is due to the strong sulfur chemisorption on the surface and within particles of the electrodic catalyst. An alternative to this problem is to pass a gaseous stream rich in methane and hydrogen at elevated temperature, which causes the gradual increase in conversion as the physically adsorbed sulfur is removed. Although poisoning appear to be partially reversible, the initial levels of conversion are not achieved because there are a slow desorption of such species [131]. In addition to the problem caused by contaminants, it is possible indeed that the temperature gradients from the Please cite this article in press as: Alves HJ, et al., Overview of hydrogen production technologies from biogas and the applications in fuel cells, International Journal of Hydrogen Energy (2010), http://dx.doi.org/10.1016/j.ijhydene.2013.02.057 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y x x x ( 2 0 1 0 ) 1 e1 1 endothermic reforming reactions cause the destruction of the electrolyte. In this case, one possible solution is to add air to the biogas, which not only prevents coke formation, but also removes the high temperature gradient due to the occurrence of exothermic reactions (complete and partial oxidation of methane) [127]. Fig. 1 shows the region with the greatest tendency to carbon deposition in the diagram of CeHeO ternary phase, when biogas internal reforming is used in SOFC fuel cells. In any type of conventional reforming used, the diagram in Fig. 1 is valid, since the C, H and O elements are always present in the molecules of the reactants (see Table 2). 4. Considerations for H2 production from biogas It is acknowledged that biogas has great potential for H2 generation through several reforming processes. However, selecting a specific process depends on several factors, some of which are: biogas composition, purity required for using H2, volume production of the desired H2, and investment availability, among others. Some of the reforming technologies mentioned in this work are already or will soon be commercialized, as for instance e SR, POR and ATR. Other newer technologies, not yet consolidated, will take some time to be commercialized, currently only used in research, such as internal reforming in fuel cells [24]. Among the existing fuel cells, the PAFC type cells have already been marketed, however they encounter problems such as durability and sensitivity to contaminants, rendering their technological route unviable. Although the PEMFC, SOFC and MCFC cells are in rapid development, they are not commercial products, but rather advanced prototypes. In natura biogas cannot be used as raw material in conventional reforming processes due to the likely poisoning of the catalyst by H2S, resulting in the rapid loss of catalytic Fig. 1 e Ternary CeHeO diagram CeHeO showing the possibility of coke formation for biogas internal reforming in SOFC. Adapted from Shiratori et al. (2010) [122]. 7 activity. For the partially treated reforming biogas (H2S removed), using a chemical composition with considerable CO2 content (30e45% vol.), the dry process is interesting, as it enables taking advantage of the CO2 intrinsically present in the composition, as an oxidant in this kind of reforming. When the biogas has a CO2/CH4 ratio lower than 1 (as it usually occurs), it is necessary to add an alternative oxidant for the production of synthesis gas. Therefore, the addition of O2 by the DOR method could be a possible route for the production of H2 from biogas, also promoting a slight increment in the H2/ CO ratio. In almost all reforming technologies, one of the main challenges is developing catalysts capable of preventing carbon deposition on the active phase in order to increase its useful life. In the case of DR, the problem is even worse, often making this type of process unfeasible due to the rapid deactivation of the catalyst. In DOR, the periodical passage of O2 flow through the catalyst bed helps the gasification of the carbon deposited on the surface, increasing the availability of catalytic active sites and temporarily/partially recovering the activity of the material. However, in both reforming cases (DR, DOR) the H2/CO ratio is usually close to 1, which restricts the H2 production potential, requiring a higher CO volume to be separated from the products by the Shift reaction, making it difficult to obtain high purity H2. Furthermore, in the DR biogas, part of the H2 produced reacts with CO2 by the reverse shift reaction (Eq. 2) producing water and CO, which reduces the production yield of H2. Thus, maximizing the H2 yield from biogas with the SR process, followed by Shift reactions, seems to be a less elegant but more feasible solution, particularly with respect to minimizing CO and maximizing H2 production. In this case, the H2/ CO ratio obtained is high (close to 3) and the technology involved better known and controlled. There are many studies which adapt biogas in SR, despite the high CO2 content, maintaining a high H2/CO ratio (between 2 and 3), as seen in Table 3 [2,3,86]. The same can occur in POR and ATR, where biogas can be used directly without drastically reducing the ratio of H2/CO [44e47,52,74,82,89,90]. Thus, ATR appears to be an attractive technique for generating H2 from biogas, from the standpoint of H2 yield, as well as for the energy efficiency achieved. Additionally, in ATR the reactor can be stopped and restarted quickly, which when the discontinuous supply of biogas and energy intake is considered, directly result in the lowest cost/benefit ratio among all the other reforming processes. When biogas is purified, that is enriched in biomethane, it has a chemical composition (93e96% of CH4, 4e7% of CO2 and <20 ppm of H2S) that enables it to be used in almost all reforming processes. The lower the CO2 content in biomethane, the more efficient the CH4 conversion in the desired products, which makes it easier to obtain high purity H2. However, it should be noted that in this case the DR and DOR processes are not the most suitable ones as CO2 has to be added to the reactor, which in turn is already removed in the previous step during the biogas purification treatment. Thus, the SR, POR and ATR processes are the most recommended ones. In any conventional reforming process using biogas as raw material, new catalysts with high catalytic activity at high Please cite this article in press as: Alves HJ, et al., Overview of hydrogen production technologies from biogas and the applications in fuel cells, International Journal of Hydrogen Energy (2010), http://dx.doi.org/10.1016/j.ijhydene.2013.02.057 8 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y x x x ( 2 0 1 0 ) 1 e1 1 temperatures must be developed. They should be chemically and thermally stable, preventing carbon deposition on its surface (coke) which consequently slows down the inactivation process. In view of the frequent treatments required to reactivate the catalyst (inside or outside the catalyst bed), or the need for periodic replacement due to its permanent deactivation, which results in production stops, the costs can be very high. This is a major obstacle for large-scale H2 production using the reforming processes. According to the operating temperature of the fuel cells, the production method of H2 can be designed/engineered. For high-temperature operating cells, H2 can be produced by internal reforming of hydrocarbons (methane or biogas). The low-temperature cells, such as PEMFC, require an external reformer (pre-reformer) using steam (SR), air (POR) or the combination of both (ATR). Thus, a combined H2 production unit with one fuel cell is a promising alternative for mobile and stationary applications in the near future. Given that storage technology and H2 distribution networks do not yet meet the expectations, fuel efficient and compact catalytic converters, such as fuel cells, are crucial. 5. Conclusion The main problems encountered in the biogas reforming processes, cited by most studies found, are related to coke formation on the catalyst surface and the poisoning by substances containing sulfur, which can lead to deactivation of the catalyst and reduction of H2 production. The Ni-based catalysts are the most used in the reform processes. Many studies focus on evaluating the effect of the catalyst support and the addition of promoter elements over coke formation. Purification of biogas for the reduction or elimination of corrosive species such as H2S is a necessary step, regardless of the process that is used. The physico-chemical methods, adopting chemical adsorption and absorption processes, have been used frequently, and initiatives involving biological processes with the use of living organisms to consume the contaminants are also found. With respect to fuel cells, both the degree of purification of H2 as the nature of the electrodic catalysts and the electrolyte used, can interfere with the functioning and efficiency in generating electricity. Cells with higher temperatures (e.g. SOFC) besides presenting higher electrical efficiency, they also have a higher tolerance to CO (50 ppm). To these cells, there are several studies that show that the bimetallic catalysts (with addition of a second metallic element beyond Pt or Ni) reduce the tendency to coke formation. In the internal biogas reforming within high temperature fuel cells, such as SOFCs, tolerance to the formed CO decreases much above 50 ppm, which can lead to carbon deposition on the electrodic catalysts, being necessary a greater control of the chemical composition of the incoming biogas. The addition of water and air to biogas and promoter elements in the electrodic catalysts are initiatives to prevent the destruction of the electrolyte and reduce the buildup of coke, respectively. references [1] Lau CS, Tsolankis A, Wyszynski ML. Biogas upgrade to syngas (H2-CO) via dry and oxidative reforming. Int J Hydrogen Energy 2011;36:397e404. [2] Effendi A, Hellgardt K, Zhang Z-G, Yoshida T. Optimising H2 production from model biogas via combined steam reforming and CO shift reactions. Fuel 2005;84:869e74. [3] Kolbitsch P, Pfeifer C, Hofbauer H. Catalytic steam reforming of model biogas. Fuel 2008;87:701e6. [4] Shiga H, Shinda K, Hagiwara K, Tsutsumi A, Sakurai M, Yoshida K, et al. Large-scale hydrogen production from biogas. Int J Hydrogen Energy 1998;23:631e40. [5] Okubo T, Hideschima Y, Shudo Y. Estimation of hydrogen output from a full-scale plant for production of hydrogen from biogas. Int J Hydrogen Energy 2010;35:13021e7. [6] Muradov N, Smith F. Thermocatalytic conversion of landfill gas and biogas to fuels. Energy Fuels 2008;22:2053e60. [7] Fierro JLG. Hydrogen and syngas from biomass. Catal Today 2012.. http://dx.doi.org/10.1016/j.cattod.2012.04.058. [8] Horikawa MS, Rossi F, Gimenes ML, Costa CMM, Silva MGC. Chemical absorption of H2S for biogas purification. Braz J Chem Eng 2004;21(3):415e22. [9] Lansing S, Botero RB, Martin JF. Waste treatment and biogas quality in small-scale agricultural digesters. Bioresour Technol 2008;99:5881e90. [10] Ferrer I, Garfı́ M, Uggetti E, Ferre-Martı́ L, Calderon A, Velo E. Biogas production in low-cost household digesters at the Peruvian Andes. Biomass Bioenerg 2011;35:1668e74. [11] Solomon KR, Lora EES. Estimate of the electric energy generating potential for different sources of biogas in Brazil. Biomass Bioenerg 2009;33:1101e7. [12] Damrongsak D, Tippayawong N. Experimental investigation of an automotive air-conditioning system driven by a small biogas engine. Appl Therm Eng 2010;30:400e5. [13] Pöschl M, Ward S, Owende P. Evaluation of energy efficiency of various biogas production and utilization pathways. Appl Energy 2010;87:3305e21. [14] Swami NS, Mallikarjuna JM, Ramesh A. An experimental study of the biogas-diesel HCCI mode of engine operation. Energy Conv Manag 2012;51(7):1347e53. [15] Iordanidis AA, Kechagiopoulos PN, Voutetakis SS, Lemonidou AA, Vasalos IA. Autothermal sorptionenhanced steam reforming of bio-oil/biogas mixture and energy generation by fuel cells: concept analysis an process simulation. Int J Hydrogen Energy 2008;31:1058e65. [16] Borgward RH. Biomass and natural gas as co-feedstocks for production of fuel-cell vehicles. Biomass Bioenerg 1997;12:333e45. [17] Levin DB, Chahine R. Challenges for renewable hydrogen production from biomass. Int J Hydrogen Energy 2010;35:4962e9. [18] Papadias DD, Ahmed S, Kumar R. Fuel quality issues with biogas energy e an economic analysis for a stationary fuel cell system. Energy 2012;44:257e77. [19] Hotza D, Da Costa JCD. Fuel cells development and hydrogen production from renewable resources in Brazil. Int J Hydrogen Energy 2008;33:4915e35. [20] Herle JV, Membrez Y, Bucheli O. Biogas as a fuel source for SOFC co-generators. J Power Sources 2004;127:300e12. [21] Faghri A, Guo Z. Challenges and opportunities of thermal management issues related to fuel cell technology and modeling: review. Int J Heat Mass Transf 2005;48:3891e920. [22] Chen Z, Grace JR, Lim CJ, Li A. Experimental studies of pure hydrogen production in a commercialized fluidized-bed membrane reactor with SMR and ATR catalysts. Int J Hydrogen Energy 2007;32:2359e66. Please cite this article in press as: Alves HJ, et al., Overview of hydrogen production technologies from biogas and the applications in fuel cells, International Journal of Hydrogen Energy (2010), http://dx.doi.org/10.1016/j.ijhydene.2013.02.057 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y x x x ( 2 0 1 0 ) 1 e1 1 [23] Armor JN. The multiple roles for catalysis in the production of H2. Appl Catal A Gen 1999;176:159e76. [24] Holladay JD, Hu J, King DL, Wang Y. An overview of hydrogen production technologies. Catal Today 2009;139:244e60. [25] Göransson K, Söderlind U, He J, Zhang W. Review of syngas production via biomass DFBGs. Renew Sust Energ Rev 2011;15:482e92. [26] Li J, Smith KJ. Methane decomposition and catalyst regeneration in a cyclic mode over supported Co and Ni catalysts. Appl Catal A Gen 2008;349:116e24. [27] Amin AM, Croiset E, Constantinou C, Epling W. Methane cracking using Ni supported on porous and non-porous alumina catalysts. Int J Hydrogen Energy 2012;37:9038e48. [28] Parkomenko K, Tyunyaev A, Tejada LMM, Komissarenko D, Dedov A, Loktev A, et al. Mesoporous amorphous silicate catalysts for biogas reforming. Catal Today 2012;189:129e35. [29] Halabi MH, Croon MHJM, Schaaf JVD, Cobden PD, Schouten JC. A novel catalyst-sorbent system for an efficient H2 production with in-situ CO2 capture. Int J Hydrogen Energy 2012;37:4987e96. [30] Sun D, Li X, Ji S, Cao L. Effect of O2 and H2O on the trireforming of the simulated biogas to syngas over Ni-based SBA-15 catalysts. J Nat Gas Chem 2010;19:369e74. [31] Barrai F, Jackson T, Whitmore N, Castaldi MJ. The role of carbon deposition on precious metal catalyst activity during dry reforming of biogas. Catal Today 2007;129:391e6. [32] Caglayan BS, Önsan ZI, Aksoylu AE. Production of hydrogen over bimetallic Pt-Ni/g-Al2O3: II. Indirect partial oxidation of LPG. Catal Lett 2005;102:63e7. [33] Muradov N, Smith F, T-Raissi A. Hydrogen production by catalytic processing of renewable methane-rich gases. Int J Hydrogen Energy 2008;33:2023e35. [34] Zhu X, Wang H, Wei Y, Li K, Cheng X. Hydrogen and syngas production from two-step steam reforming of methane over CeO2-Fe2O3 oxygen carrier. J Rare Earths 2010;28(6):907e12. [35] Boyano A, Blanco-Marigorta AM, Morosuk T, Tsatsaronis G. Exergoenvironmental analysis of a steam methane reforming process for hydrogen production. Energy 2011;36:2202e14. [36] Zhai X, Ding S, Liu Z, Jin Y, Cheng Y. Catalytic performance of Ni catalysts for steam reforming of methane at high space velocity. Int J Hydrogen Energy 2011;36:482e9. [37] Zhai X, Ding S, Cheng Y, Jin Y, Cheng Y. CFD simulation with detailed chemistry of steam reforming of methane for hydrogen production in an integrated micro-reactor. Int J Hydrogen Energy 2010;35:5383e92. [38] Gallucci F, Paturzo L, Basile A. A simulation study of the steam reforming of methane in a dense tubular membrane reactor. Int J Hydrogen Energy 2004;29:611e7. [39] Maluf SS, Assaf EM. Ni catalysts with Mo promoter for methane steam reforming. Fuel 2009;88:1547e53. [40] Zhai X, Cheng Y, Zhang Z, Jin Y, Cheng Y. Steam reforming of methane over Ni catalyst in micro-channel reactor. Int J Hydrogen Energy 2011;36:7105e13. [41] Roh H-S, Eum I-H, Jeong D-W. Low temperature steam reforming of methane over Ni-Ce(1-x)Zr(x)O2 catalysts under severe conditions. Renew Energy 2012;42:212e6. [42] Iulianelli A, Manzolini G, Falco M, Campanari S, Longo T, Liguori S, et al. H2 production by low pressure methane steam reforming in a Pd-Ag membrane reactor over a Nibased catalyst: experimental and modeling. Int J Hydrogen Energy 2010;35:11514e24. [43] Fonseca A, Assaf EM. Production of the hydrogen by methane steam reforming over nickel catalysts prepared from hydrotalcite precursors. J Power Sourc 2005;142:154e9. [44] Corbo P, Migliardini F. Hydrogen production by catalytic partial oxidation of methane and propane on Ni and Pt catalysts. Int J Hydrogen Energy 2007;32:55e66. 9 [45] Ruckenstein E, Hu YH. Methane partial oxidation over NiO/ MgO solid solution catalysts. Appl Catal A Gen 1999;183:85e92. [46] Rogatis L, Montini T, Cognigni A, Olivi L, Fornasiero P. Methane partial oxidation on NiCu-based catalysts. Catal Today 2009;145:176e85. [47] Zhang X, Lee CS-M, Hayward DO, Mingos DMP. Oscillatory behaviour observed in the rate of oxidation of methane over metal catalysts. Catal Today 2005;105:283e94. [48] Choudhary VR, Mondal KC, Choudhary TV. Partial oxidation of methane to syngas with or without simultaneous steam or CO2 reforming over a high-temperature stableNiCoMgCeOx supported on zirconia-hafnia catalyst. Appl Catal A Gen 2006;306:45e50. [49] Dantas SC, Resende KA, Rossi RL, Assis AJ, Hori CE. Hydrogen production from oxidative reforming of methane on supported nickel catalysts: an experimental and modeling study. Chem Eng J 2012;197:407e13. [50] Omata K, Kobayashi S, Horiguchi J, Kobayashi Y, Yamazaki Y, Yamada M. Kinetic model of K-Ni/a-Al2O3 catalyst for oxidative reforming of methane determined by genetic algorithm. Appl Catal A Gen 2012;425e426:170e7. [51] Jing QS, Zheng XM. Combined catalytic partial oxidation and CO2 reforming of methane over ZrO2-modified Ni/SiO2 catalysts using fluidized-bed reactor. Energy 2006;31:2184e92. [52] Mosayebi Z, Rezaei M, Ravandi AB, Hadian N. Autothermal reforming of methane over nickel catalysts supported on nanocrystalline MgAl2O4 with high surface area. Int J Hydrogen Energy 2012;37:1236e42. [53] Souza MMVM, Schmal M. Autothermal reforming of methane over Pt/ZrO2/Al2O3 catalysts. Appl Catal A Gen 2005;281:19e24. [54] Halabi MH, Croon MHJM, Schaaf JVD, Cobden PD, Schouten JC. Modeling and analysis of autothermal reforming of methane to hydrogen in a fixed bed reformer. Chem Eng J 2008;137:568e78. [55] Simeone M, Salemme L, Allouis C. Reactor temperature profile during autothermal methane reforming on Rh/Al2O3 catalyst by IR imaging. Int J Hydrogen Energy 2008;33:4798e808. [56] Cai X, Dong X, Lin W. Autothermal reforming of methane over Ni catalysts supported on CuO-ZrO2-CeO2-Al2O3. J Nat Gas Chem 2006;15:122e6. [57] Dantas SC, Escritori JC, Soares RR, Hori CE. Effect of different promoters on Ni/CeZrO2 catalyst for autothermal reforming and partial oxidation of methane. Chem Eng J 2010;156:380e7. [58] Fidalgo B, Domı́nguez A, Pis JJ, Menéndez JA. Microwaveassisted dry reforming of methane. Int J Hydrogen Energy 2008;33:4337e44. [59] Oyama ST, Hacarlioglu P, Gu Y, Lee D. Dry reforming of methane has no future for hydrogen production: comparison with steam reforming at high pressure in standard and membrane reactors. Int J Hydrogen Energy 2012;37:10444e59. [60] Bereketidou OA, Goula MA. Biogas reforming for syngas production over nickel supported on ceria-alumina catalysts. Catal Today 2012;195(1):93e100. [61] San-José-Alonso D, Juan-Juan J, Illán-Gómes MJ, RománMartı́nez MC. Ni, Co and bimetallic Ni-Co catalysts for the dry reforming of methane. Appl Catal A Gen 2009;371:54e9. [62] Serrano-Lotina A, Martin AJ, Folgado MA, Daza L. Dry reforming of methane to syngas over La-promoted hydrotalcite clay-derived catalysts. Int J Hydrogen Energy 2012;37:12342e50. [63] Eltejaei H, Bozorgzadeh HR, Towfighi J, Omidkhah MR, Rezaei M, Zanganeh R, et al. Methane dry reforming on Ni/ Please cite this article in press as: Alves HJ, et al., Overview of hydrogen production technologies from biogas and the applications in fuel cells, International Journal of Hydrogen Energy (2010), http://dx.doi.org/10.1016/j.ijhydene.2013.02.057 10 [64] [65] [66] [67] [68] [69] [70] [71] [72] [73] [74] [75] [76] [77] [78] [79] [80] [81] i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y x x x ( 2 0 1 0 ) 1 e1 1 Ce0.75Zr0.25O2-MgAl2O4 and Ni/Ce0.75Zr0.25O2-g-alumina: effects of support composition and water addition. Int J Hydrogen Energy 2012;37:4107e18. Izquierdo U, Barrio VL, Lago N, Requies J, Cambra JF, Güemez MB, et al. Biogas steam and oxidative reforming processes for synthesis gas and hydrogen production in conventional and microreactor reaction systems. Int J Hydrogen Energy 2012;37:13829e42. Chen L, Zhu Q, Hao Z, Zhang T, Xie Z. Development of a Co-Ni bimetallic aerogel catalyst for hydrogen production via methane oxidative CO2 reforming in a magnetic assisted fluidized bed. Int J Hydrogen Energy 2010;35:8494e502. Choudhary R, Mondal KC. CO2 reforming of methane combined with steam reforming or partial oxidation of methane to syngas over NdCoO3 perovskite-type mixed metal-oxide catalyst. Appl Energy 2006;83:1024e32. Gao J, Hou Z, Liu X, Zeng Y, Luo M, Zheng X. Methane autothermal reforming with CO2 and O2 to synthesis gas at the boundary between Ni and ZrO2. Int J Hydrogen Energy 2009;34:3734e42. Khalaf P, Souza IG, Carasek E, Debacher NA. Production of synthesis gás by thermal plasma via pyrolysis of methane and carbon dioxide. Quim Nova 2011;34(9):1491e5. Yang Y-C, Lee B-J, Chun Y-N. Characteristics of methane reforming using gliding arc reactor. Energy 2009;34:172e7. Chun YN, Yang YC, Yoshikawa K. Hydrogen generation from biogas reforming using a gliding arc plasma-catalyst reformer. Catal Today 2009;148:283e9. Zhu B, Li X-S, Shi C, Liu J-L, Zhao T-L, Zhu A- M. Pressurization effect on dry reforming of biogas in kilohertz spark-discharge plasma. Int J Hydrogen Energy 2012;37:4945e54. Hermes NA. Hydrogen and carbon nanotubes by catalytic decomposition of methane: performance of catalysts based on cobalt and aluminum [dissertation]. Porto Alegre (Brazil): Federal University of Rio Grande do Sul; 2010. Labanca ARC. Development of the plasma pyrolysis reactor for the decomposition of the methane in hydrogen and solid carbon [thesis]. Rio de Janeiro (Brazil): Federal University of Rio de Janeiro; 2007. Araki S, Hino N, Mori T, Hikazudani S. Autothermal reforming of biogas over a monolithic catalyst. J Nat Gas Chem 2010;19:477e81. Araki S, Hino N, Mori T, Hikazudani S. Durability of a Ni based monolithic catalyst in autothermal reforming of biogas. Int J Hydrogen Energy 2009;34:4727e34. Abatzoglou N, Boivin S. A review of biogás purification processes. Biofuels Bioprod Bioref 2009;3:42e71. Sousa FF, Sousa HAS, Oliveira AC, Junior MCC, Ayala AP, Barros EB, et al. Nanostructured Ni-containing spinel oxides for the dry reforming of methane: effect of the presence of cobalt and nickel on the deactivation behavior of catalysts. Int J Hydrogen Energy 2012;37:3201e12. Djinovı́c P, Crnivec IGO, Erjavec B, Pintar A. Influence of active metal loading and oxygen mobility on coke-free dry reforming of Ni-Co bimetallic catalysts. Appl Catal B Environ 2012;125:259e70. Adesina AA. The role of CO2 in hydrocarbon reforming catalysis: friend or foe? Curr Opin Chem Eng 2012;1:272e80. Muradov N, Smith F, Garceau N. Dry reforming of biogas to syngas and hydrogen for fuel cell applications. In: Proceedings of the spring meeting & 5th global congress on process safety/09 AIChE - American Institute of Chemical Engineering; 2009 May. Tampa, Florida, p. 45a. Xuan J, Leung MKH, Leung DYC, Ni M. A review of biomassderived fuel processors for fuel cell systems. Renew Sust Energ Rev 2009;13:1301e13. [82] Trimm DL. Catalysts for the control of coking during steam reforming. Catal Today 1999;49:3e10. [83] Lisboa JS, Santos DCRM, Passos FB, Noronha FB. Influence of the addition of promoters to steam reforming catalysts. Catal Today 2005;101:15e21. [84] Silva LC. Optimization of hydrogen production by steam reforming of methane in membrane reactor laboratory [dissertation]. Uberlândia (Brazil): Federal University of Uberlândia; 2008. [85] Lin Y, Liu S, Chuanga C, Chub Y. Effect of incipient removal of hydrogen through palladium membrane on the conversion of methane steam reforming: experimental and modeling. Catal Today 2003;82:127e39. [86] Lu GQ, Diniz-Costa JC, Dukec M, Giessler S, Socolowe R, Williams RH, et al. Inorganic membranes for hydrogen production and purification: a critical review and perspective. J Colloid Interface Sci 2007;314:589e603. [87] Sato T, Suzuki T, Aketa M, Ishiyama Y, Mimura K, Itoh N. Steam reforming of biogas mixtures with a palladium membrane reactor system. Chem Eng Sci 2010;65:451e7. [88] Ávila-Neto CN. Thermodynamic analysis of the reforms methane (oxidation and autothermal) of ethanol and naphtha [dissertation]. Uberlândia (Brazil): Federal University of Uberlândia; 2009. [89] Zhu J, Van-Ommen JG, Knoester A, Lefferts L. Effect of surface composition of yttrium-stabilized zirconia on partial oxidation of methane to synthesis gas. J Catal 2005;230:291e300. [90] Escritori JC. Autothermal reforming of methane to Ni/ CeZrO2/Al2O3 catalysts for the production of hydrogen [dissertation]. Uberlândia (Brazil): Federal University of Uberlândia; 2007. [91] Horn R, Williams KA, Degenstein NJ, Bitsch-Larsen A, Nogare DD, Tupy SA, et al. Methane catalytic partial oxidation on autothermal Rh and Pt from catalysts: oxidation and reforming zones, transport effects, and approach to thermodynamic equilibrium. J Catal 2007;249:380e93. [92] Lucrédio AF, Assaf JM, Assaf EM. Reforming of a model biogás on Ni and Rh-Ni catalysts: effect of adding La. Fuel Process Tech 2012;102:124e31. [93] Gallucci F, Tosti S, Basile A. Pd-Ag tubular membrane reactors for methane dry reforming: a reactive method for CO2 consumption and H2 production. J Membr Sci 2008;317:96e105. [94] Djaidja A, Libs S, Kiennemann A, Barama A. Characterization and activity in dry reforming of methane on NiMg/Al and Ni/MgO catalysts. Catal Today 2006;113:194e200. [95] Chang JS, Hong DY, Li X, Park S. Thermogravimetric analyses and catalytic behaviors of zirconia-supported nickel catalysts for carbon dioxide reforming of methane. Catal Today 2006;115:186e90. [96] Ferreira OLS. Conversion of biogas into synthesis gas via reforming reactions of methane with CO2 and steam on catalysts Ni-Al-Y [dissertation]. São Carlos (Brazil): University of São Paulo; 2010. [97] Lima SM, Assaf JM. Preparation and characterization of LaNi(1-x)CoxO3 perovskites as catalyst precursors for synthesis gas generation by CO2 reforming of methane. Quim Nova 2007;30(2):298e303. [98] Valentini A, Probst LF, Carreño NLV, Leite ER, Pontes FM, Longo E, et al. Microstructural study of Ni/gAl2O3 catalyst e addition effects of CeO2 on carbon dioxide reforming of methane. Quim Nova 2003;26(4):648e54. [99] Sousa HSA, Silva NA, Castro AJR, Campos A, Filho JM, Oliveira AC. Mesoporous catalysts for dry reforming of Please cite this article in press as: Alves HJ, et al., Overview of hydrogen production technologies from biogas and the applications in fuel cells, International Journal of Hydrogen Energy (2010), http://dx.doi.org/10.1016/j.ijhydene.2013.02.057 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y x x x ( 2 0 1 0 ) 1 e1 1 [100] [101] [102] [103] [104] [105] [106] [107] [108] [109] [110] [111] [112] [113] [114] [115] methane: correlation between structure and deactivation behaviour of Ni-containing catalysts. Int J Hydrogen Energy 2012;37:12281e91. Serrano-Lotina A, Rodrı́guez L, Muñoz G, Martin AJ, Folgado MA, Daza L. Biogas reforming over La-NiMgAl catalysts derived from hydrotalcite-like structure: influence of calcinations temperature. Catal Commun 2011;12:961e7. Xu J, Zhou W, Li Z, Wang J, Ma J. Biogas reforming for hydrogen production over nickel and cobalt bimetallic catalysts. Int J Hydrogen Energy 2009;34:6646e54. Nakamura J, Aikawa K, Sato K, Uchijima T. Role of support reforming of CH4 over Rh catalysts. Catal Lett 1994;25:265e70. Choudhary VR, Mamman AS. Simultaneous oxidative conversion and CO2 or steam reforming of methane to syngas over a CoO-NiO-MgO catalyst. J Chem Tech Biotechnol 1998;73:345e50. Ashcroft AT, Cheetham AK, Green MLH, Vernon PDF. Partial oxidation of methane to syngas using carbon dioxide. Nature 1991;352:225e6. Avraam DG, Halkides TI, Liguras DK, Bereketidou AO, Goula MA. An experimental and theoretical approach for the biogas steam reforming reaction. Int J Hydrogen Energy 2010;35:9818e27. Effendi A, Zhang Z-G, Hellgardt K, Honda K, Yoshida T. Steam reforming of a clean model biogas over Ni/Al2O3 in fluidized- and fixed-bed reactors. Catal Today 2002;77:181e9. Asencios YJO, Bellido JDA, Assaf EM. Synthesis of NiO-MgOZrO2 catalysts and their performance in reforming of model biogas. Appl Catal A Gen 2011;397:138e44. Naidja A, Krishna CR, Butcher T, Mahajan D. Cool flame partial oxidation and its role in combustion and reforming of fuels for fuel cell systems. Prog Energy Combust Sci 2003;29:155e91. Goula G, Kiousis V, Nalbandian L, Yentekakis IV. Catalytic and electrocatalytic behavior of Ni-based cermet anodes under internal dry reforming of CH4 þ CO2 mixtures in SOFCs. Solid State Ion 2006;177:2119e23. Zhang S, Yuan X, Hin JNC, Wang H, Friedrich KA, Schulze M. A review of platinum-based catalyst layer degradation in proton exchange membrane fuel cells. J Power Sources 2009;194(2):588e600. Wu J, Martin JJ, Wang H, Zhang J, Shen J, Wu S, et al. A review of PEM fuel cell durability: degradation mechanisms and mitigation strategies. J Power Sources 2008;184(1):104e19. Vielstich W. Ideal and effective efficiencies of cell reactions and comparison to Carnot cycles. In: Vielstich W, editor. Handbook of fuel cells: fundamentals, technology and applications. New York: John Wiley; 2003. p. 26e30. Ahmed S, Krumpelt M. Hydrogen from hydrocarbon fuels for fuel cells. Int J Hydrogen Energy 2001;26:291e301. Cipitı́ F, Pino L, Vita A, Lagana M, Recupero V. Performance of a 5 kW and fuel processor for polymer electrolyte fuel cells. Int J Hydrogen Energy 2008;33:3197e203. Uribe FA, Valerio JA, Garzon FH, Zawodzinski TA. PEMFC reconfigured anodes for enhancing CO tolerance with air bleed. Electrochem Solid State Lett 2004;7(10):A376e9. 11 [116] Adcock PA, Pacheco SK, Norman KM, Uribe FA. Transition metal oxides as reconfigured fuel cell anode catalysts for improved CO tolerance: polarization data. J Electrochem Soc 2005;152(2):A459e66. [117] Schimidt VM, Oetjen HF, Divisek J. Performance improvement of a PEMFC using fuels with CO by addition of oxygen-evolving compounds. J Electrochem Soc 1997;144(9):L237e8. [118] Ge Q, Desai S, Neurock M, Kourtakis K. CO adsorption on PtRu surface alloys and on the surface of Pt-Ru bulk alloy. J Phys Chem B 2001;105(39):9533e6. [119] Lee D, Hwang S, Lee I. A study on composite PtRu(1:1)PtSn(3:1) anode catalyst for PEMFC. J Power Sources 2005;145(2):147e53. [120] Mukerjee S, Lee SJ, Ticianelli EA, McBreen J, Grgur BN, Markovic NM, et al. Investigation of enhanced CO tolerance in proton exchange membrane fuel cells by carbon supported PtMo alloy catalyst. Electrochem Solid State Lett 1999;2(1):12e5. [121] Santiago EI, Ticianelli EA. The performance of carbonsupported PtOs electrocatalysts for the hydrogen oxidation in the presence of CO. Int J Hydrogen Energy 2005;30(2):159e65. [122] Shiratori Y, Ijichi T, Oshima T, Sasaki K. Internal reforming SOFC running on biogas. Int J Hydrogen Energy 2010;35:7905e12. [123] Takahashi Y, Shiratori Y, Furuta S, Sasaki K. Thermomechanical reliability and catalytic activity of Ni-Zirconia anode supports in internal reforming SOFC running on biogas. Solid State Ion 2012;225:113e7. [124] Mogensen D, Grunwaldt J-D, Hendriksen PV, DamJohansen K, Nielsen JU. Internal steam reforming in solid oxide fuel cells: status and opportunities of kinetic studies and their impact on modelling. J Power Sources 2011;196:25e8. [125] Shiratori Y, Oshima T, Sasaki K. Feasibility of direct-biogas SOFC. Int J Hydrogen Energy 2008;33:6316e21. [126] Assabumrungrat S, Laosiripojana N, Piroonlerkgul P. Determination of the boundary of carbon formation for dry reforming of methane in a solid oxide fuel cell. J Power Sources 2006;159:1274e82. [127] Lanzini A, Leone P. Experimental investigation of direct internal reforming of biogas in solid oxide fuel cells. Int J Hydrogen Energy 2010;35:2463e76. [128] Benito M, Garcı́a S, Ferreira-Aparicio P, Serrano LG, Daza L. Development of biogas reforming Ni-La-Al catalysts for fuel cells. J Power Sources 2007;169:177e83. [129] Bonura G, Cannilla C, Frusteri F. Ceria-gadolinia supported NiCu catalyst: a suitable system for dry reforming of biogas to feed a solid oxide fuel cell (SOFC). Appl Catal B Environ 2012;121e122:135e47. [130] Silva AL, Dick LFP, Müller IL. Performance of a PEMFC system integrated with a biogas chemical looping reforming processor: a theoretical analysis and comparison with other fuel processors (steam reforming, partial oxidation and auto-thermal reforming). Int J Hydrogen Energy 2012;37:6580e600. [131] Farinha JFB. Methane steam reforming in reformer of the laboratory scale [dissertation]. Lisbon (Portugal): Technical University of Lisbon; 2008. Please cite this article in press as: Alves HJ, et al., Overview of hydrogen production technologies from biogas and the applications in fuel cells, International Journal of Hydrogen Energy (2010), http://dx.doi.org/10.1016/j.ijhydene.2013.02.057

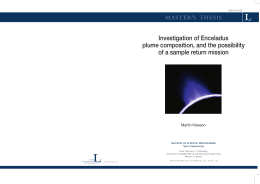

Baixar