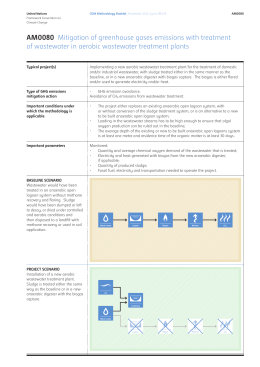

IBP1489_06 SEWAGE BIOGAS, PRODUCTION AND ELETRIC ENERGY GENERATION 1 2 Moreira, José Roberto ; Coelho, SuaniTeixeira ; Velázquez, Sílvia Maria Stortini 3 4 5 6 González ; Silva, Orlando Cristiano ; Pecora, Vanessa ; Abreu, Fernando Castro . SEWAGE BIOGAS, PRODUCTION AND ELETRIC ENERGY GENERATION Moreira, José Roberto1; Coelho, Suani Teixeira2; Velázquez, Sílvia Maria Stortini González3; Silva, Orlando Cristiano4; Pecora, Vanessa5; Abreu, Fernando Castro6. Copyright 2006, Instituto Brasileiro de Petróleo e Gás - IBP Este Trabalho Técnico foi preparado para apresentação na Rio Oil & Gas Expo and Conference 2006, realizada no período de 11 a 14 de setembro de 2006, no Rio de Janeiro. Este Trabalho Técnico foi selecionado para apresentação pelo Comitê Técnico do evento, seguindo as informações contidas na sinopse submetida pelo(s) autor(es). O conteúdo do Trabalho Técnico, como apresentado, não foi revisado pelo IBP. Os organizadores não irão traduzir ou corrigir os textos recebidos. O material conforme, apresentado, não necessariamente reflete as opiniões do Instituto Brasileiro de Petróleo e Gás, seus Associados e Representantes. É de conhecimento e aprovação do(s) autor(es) que este Trabalho Técnico seja publicado nos Anais da Rio Oil & Gas Expo and Conference 2006. Resumo O Centro Tecnológico de Hidráulica (CTH) da Universidade de São Paulo (USP) trata o esgoto gerado pelo Conjunto Residencial da USP (CRUSP) e pelo principal restaurante do Campus, por meio do processo de digestão anaeróbia, cujos principais produtos são biogás e lodo, além do efluente com carga reduzida de Demanda Bioquímica de Oxigênio (DBO). Por meio do Programa de Uso Racional de Energia e Fontes Alternativas (PUREFA), que é um projeto da USP, financiado pela FINEP, em parceria com o Centro Nacional de Referência em Biomassa (CENBIO) e a Escola Politécnica da USP e do CTH, em um edital voltado à infra-estrutura (CT-INFRA), o biogás produzido é tratado e alimenta um motor para gerar energia elétrica. O PUREFA teve três objetivos principais: implantar medidas de gestão e ação de eficiência energética permitindo reduzir o consumo de energia elétrica na Universidade; ampliar a geração distribuída na USP a partir de recursos renováveis e não convencionais de energia e implantar políticas de incentivo ao uso eficiente e racional de energia. Entre as 14 metas integrantes deste projeto, o CENBIO comprometeu-se em realizar duas. As atividades incluíam a implementação de um sistema de captação, purificação e armazenamento do biogás gerado no CTH, além da geração de eletricidade utilizando o biogás como combustível em motor ciclo Otto. Palavras-chave: biomassa, biodigestor, biogás, geração de eletricidade. Abstract The PUREFA (Program of Rational Energy Use and Alternative Sources), compound by 14 purposes, is about a project of the USP – University of Sao Paulo, financial backer FINEP – Financier of Studies and Projects. This project had three main objectives: to implant measures of management and action of energy efficiency, to increase the distributed generation in USP from the renewable source and not conventional energy and to introduce incentive permanent politics to the efficient and rational use of energy. In this context, the CENBIO was responsible for two purposes, related to the biogas use for electricity generation. The first, purpose 11, had main objective to implant the generation system, to capture and to stock the biogas, produced by biodigestor in the Technological Hydraulically Center (CTH – USP). Finished this stage, was started the purpose 12, regarding biogas used as fuel for electricity generation using a generator group Otto cycle. Nowadays this project is a demonstrative project. In this article the technical and environmental project results obtained will be presented. Keywords: Biogas, renewable energy, energy generation. 1. Introduction ______________________________ 1 Doutor, Engenheiro – Instituto de Eletrotécnica e Energia – Universidade de São Paulo; 2 Doutora, Engenheira Química – Centro de Referencia Nacional em Biomassa; 3 Mestre, Geólogo – Centro de Referencia Nacional em Biomassa; 4 Mestre, Engenheira Química - Centro de Referencia Nacional em Biomassa; 5 Bacharel, Engenheiro Mecânico - Centro de Referencia Nacional em Biomassa. Rio Oil & Gas Expo and Conference 2006 The PUREFA (Program of Rational Energy Use and Alternative Sources), compound by 14 purposes, is about a project of the USP – University of Sao Paulo, financial backer FINEP – Financier of Studies and Projects. This project had three main objectives: to implant measures of management and action of energy efficiency, to increase the distributed generation in the USP from the renewable resource and not conventional energy and to introduce incentive permanent politics to the efficient and rational use of energy. In the context, the Brazilian Reference Center on Biomass was responsible for two purposes, related to the biogas use for electricity generation. The first, purpose 11, had main objective to implant the generation system, to capture and to stock the biogas, produced by biodigestor in the Technological Hydraulically Center (CTH – USP). The biodigestor is a UASB (Upflow Anaerobic Sludge Blanket), whose biogas production outflow is around 4 m3/day, opera rates 24 hours per day and utilize the sewer from the residential buildings located in Sao Paulo University, inside the campus. For the biogas utilization, was made its outflow, chemical composition and heat value identifications, parameters that allowed to determinate the real potential for generation and to shown the necessity of the previous treatment, as H2S removal. Finished this stage, was started the purpose 12, regarding biogas used as fuel for electricity generation using a generator group Otto cycle. Nowadays this project is a demonstrative project. In this article the technical and environmental project results obtained will be presented. 2. Biogas Purification The biogas purification system (Figure 1), which aims to remove sulfidric components and humidity from biogas, occurs in tree steps. In the first step the most of biogas humidity is removed, by a recipient where the water is condensed. After that, in second step, biogas is directed to purification system, composed by two molecular screens, removing the remainder humidity and the sulfídrico components (H2S). In the third step, biogas pass trough an amount of iron chip, removing the H2S residual. To prove the purification system efficiency and to determine the biogas chemical composition, two analysis were required, one before the purification process and other after it. These results are presented on Tables 2 and 3. Figure 1 – Biogas Purification System 3. The Civil Construction engine. A civil construction (Figure 2) was made to shelter the gasholder, the mass flow measurer and the biogas 2 Rio Oil & Gas Expo and Conference 2006 Figure 2 – The Civil Construction 4. Mass Flow Meassurer At first, a biogas mass flow measurer was installed on biodigestor side, allowing the electric energy potential determination, achieving a value of 4 m3/day. Having this data and the civil construction completed, it was moved to the civil construction and reinstalled before the gasholder to monitor the biogas storage (Figure 3). Figure 3 – Biogas Mass Flow Measurer 5. Biogas Storage Due to the low biogas mass flow values, it must be stored before it use as fuel to produce electric energy. Thus this project includes a gasholder (Figure 4), able to store 10 m3 of biogas, made by PVC. Its dimensions are: external diameter 2 m, length 3,2 m and thickness of 2 mm. Figure 4 - Gasholder 3 Rio Oil & Gas Expo and Conference 2006 6. Eletric Generation Engine The appropriate purification system contributes to improve the combustion fuel conditions. Other data obtained from biogas analysis is referent to the low heat value that combined to the efficiency and biogas consumption is important to estimate the electric generation potential, as showed in equation 1 η = W [EQUATION 1] Mb*LHV (1) W – Estimated Power; Mb – Biogas mass flow consumption; LHV – Low heat value; η - Efficiency To procedure the calculation above is necessary to admit the efficiency, which depends on technology used in biogas conversion, basically including three different technologies: gas turbines, microturbines and Otto Cycle engines. In this project, due to the low mass flow of biogas produced, Otto Cycle engine has been pointed as the appropriate technology. The Otto engine (Figure 6) selected presents 18 kW of installed power and it biogas demand is around 5,6 m3/ hour. Figure 6 – Engine 4 Rio Oil & Gas Expo and Conference 2006 6. Project Installations After the biogas has passed in through the tubing, the water accumulator, adsorbent material, the molecular screen and the iron chips, it is ready to be stored in a gasholder (flexible tank made with PVC) and be employed in Otto engine as fuel to produce electricity. A project scheme is present in figure 5, jointly with the equipments description on table 1: Table 1 Equipments employed description Equipament Number Amount Tubing 1 1 Sewer Measurer of Outflow 2 1 Biodigestor 3 1 Water Accumulator 4 1 Valve Sphere 5 6 Adsorbent Material and 6 1 Molecular Ciever Iron Chips 7 1 Biogas Measurer of Outflow 8 1 Manometer 9 1 Pillow Tank 10 1 Engine/Generator 11 1 INFL Figure 5 – Project Scheme 7. Results and Discussions The tables 2 and 3 present the results of the biogas composition before and after the purification system, respectively. The cost of each gas analysis (biogas composition and exhaustion gases) was around U$ 1000,00 (U$1,00 = R$2,40). 5 Rio Oil & Gas Expo and Conference 2006 Table 2 Biogas Composition Before the Purification Process Chemical Components %Vol or ppm O2 (Oxygen) 1,23% N2 (Nitrogen) 15,5% CO2 (Dioxide Carbon) 4,75% CH4 (Methane) 75,8% H2S (Sulfate Hydrogen) 649 ppm H2O (water) 2,62% Table 3 Biogas Composition after the Purification Process Chemical Components O2 (Oxygen) N2 (Nitrogen) CO2 (Dioxide Carbon) CH4 (Methane) H2S (Sulfate Hydrogen) H2O (water) %Vol. or ppm 0,89% 13,2% 4,07% 80,8% < 1,0 ppm 0,98% According to that analysis occurred a significant reduction of H2S and water in biogas composition, achieving safe values to engine operational conditions, allowing the continuity of this project. The civil construction, where the biogas engine and gasholder would be installed, could be done. Having all equipments installed and the gasholder full of biogas, the engine was started. The electric demand was simulated by a test panel (Figure 7). The demand was 2,4 kW. Figure 7 – Test Panel table 4. It is in this scene that the analyses of the exhaustion gases had been made and its results are presented in the 6 Rio Oil & Gas Expo and Conference 2006 Table 4 - Exhaustion gases Component Analyses 10:38 h 11:00 h 11:10 h 11:20 h Total hydrocarbons as CH4 3,1% 0,67% 2,7% 0,19% Carbon monoxide (CO) ppm 641 929 787 922 Carbon dioxide (CO2) 8,8% * 8,4% * Nitrogen oxides (NOx) 5 ppm 15 ppm 48 ppm 65 ppm Oxygen (O2) 3,7% 5,4% 5,7% * Sulphur dioxide (SO2) < 1 ppm < 1 ppm <1 ppm <1 ppm At first, the engine functioned pretty well, but when the pressure inside the gasholder goes down, the engine starts to fail. Therefore we had to put some weights on top of the gasholder to increase its pressure, and so, the problem was solved. 8. Conclusions Despite the fact that this project has been developed experimentally in Sao Paulo University’s campus, in urban area, one of the expectations is that the results obtained provide information about biodigestor´s operational conditions. This allows defining appropriate areas where this project could be applicable. Especially in rural areas, the use of swage as fuel to produce electric energy is able to contribute with electrification programs already structured in Brazil, increasing decentralized electric generation, what creates important benefits to the country. The most important environmental contribution associated to this project is the mitigation of greenhouse gases (GHG) emissions, especially verified trough methane conversion in carbon dioxide, which presents a dangerous level around twenty five times lower than methane. 8. References ALVES, J.W.S., Diagnóstico técnico institucional da recuperação e uso energético do biogás gerado pela digestão anaeróbia de resíduos, dissertação apresentada ao Programa Interunidades de Pós Graduação em energia da Universidade de São Paulo para obtenção do título de Mestre em Energia, 2000 AVELLAR, L.H.N., A valorização dos subprodutos agroindustriais visando a co-geração e a redução da poluição ambiental, Tese apresentada à faculdade de engenharia de Guaratinguetá, unesp- para a obtenção do título de Doutor em Engenharia Mecânica , Guaratinguetá, 2001. BENICASA, M., ORTOLANI, A. F., JÚNIOR, L. J., Biodigestores Convencionais, Departamento de Engenharia Rural da Faculdade de Ciências Agrárias e Veterinárias – UNESP, Campus de Jaboticabal, p/1-15, 1990. CLAASSEN, P.A.M., LIER, J.B., STAMS A.J.M., Utilization of biomass for supply of energy carrier, Applied microbiology and biotechnology, v.5,p741-755, 1999 ROSS, C.C., DRAKE, T.J., The handbook of Biogas Utilization, U.S. Department of Energy Southeastern Regional Biomass Energy Program Tennessee Valley Authority, Muscle Shoals, Alabama, Second Edition, July 1996. 7

Baixar