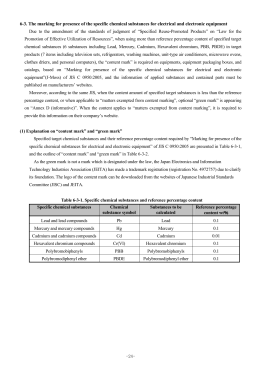

SUBSTÂNCIAS QUÍMICAS PERIGOSAS E O SETOR ELÉTRICO Em fevereiro deste ano a ONU e OMS lançaram atualização do relatório sobre o impacto de produtos químicos do dia a dia, que tem relação com os produtos do setor eletroeletrônico. Número de químicos que têm efeitos endocrinológicos aumentou 'dramaticamente', aponta estudo Componentes químicos artificiais presentes no nosso dia a dia podem ter um impacto significativo no sistema hormonal, favorecendo o desenvolvimento de doenças, de problemas de fertilidade e males congênitos, informa um estudo da ONU divulgado nesta terça-feira. O estudo diz que o número de químicos EDCs - químicos com efeitos endocrinológicos, na sigla em inglês - aumentou "dramaticamente" na última década, e muitos não são testados quanto a seus efeitos na saúde humana e na vida selvagem. O sistema endócrino humano é responsável por controlar um amplo número de processos no corpo através do uso de hormônios e moléculas relacionadas (citocinas e neurotransmissores), como a diferenciação das células/formação de órgãos no feto, assim como sistemas nervoso, reprodutivo, imunológico, metabólico e de saciedade na vida adulta). Produtos químicos disruptores endócrinos são aqueles que interferem com a ação hormonal normal, atuando de forma similar aos hormônios, em baixas concentrações, causando prolemas de infertilidade, alteração da puberdade, menopausa prematura, obesidade, dificuldades de aprendizado e memória, diabetes, câncer de próstata, doença de Alzheimer e problemas cardíacos, dentre outros. Eles incluem aditivos em embalagens, bens de consumo (eletrônicos, móveis, produtos de limpeza), produtos de cuidados pessoais (xampus, cremes, sabão) e farmacêuticos. EDCs are found among many classes of chemicals, including POPs, current-use pesticides, phytoestrogens, metals, active ingredients in pharmaceuticals, and additives or contaminants in food, personal care products, cosmetics, plastics, textiles and construction materials. "Humanos estão expostos a EDCs por diversas formas, incluindo ingestão de comida, poeira, água, inalação e pela pele", aponta o relatório, feito em parceria da Organização Mundial da Saúde e a agência da ONU para o meio ambiente (Unep). "Esses químicos vêm de fontes variadas, entram no meio ambiente durante a produção, combustão de resíduos, emissões o uso ou a eliminação de químicos e produtos e provocam diferentes (efeitos)." O problema, diz o relatório, é que é ainda há poucos dados sobre como esses EDCs são produzidos e onde são colocados. A grande maioria dos produtos colocados no mercado não são testados especificamente para avaliar os EDC’s. The doses declared safe are not actually tested, nor are the mixtures. no sistema hormonal e sua Também faltam estudos detalhados sobre seus efeitos relação com doenças específicas. O que se acredita é que a exposição a muitos desses químicos pode estar ligada a casos de câncer de mama, tireoide e próstata, deformações em bebês, hiperatividade em crianças, diabetes, asma, obesidade, males de Alzheimer e Parkinson, derrames e queda de fertilidade. Crianças podem entrar em contato com EDCs no ventre da mãe ou na infância, colocando coisas na boca. Produtos químicos Entre os produtos químicos que, segundo a ONU, podem alterar o sistema hormonal estão ftalatos (usados em plásticos maleáveis e na produção de brinquedos, perfumes e farmacêuticos, inclusive desodorantes); bisfenol A (também chamado BPA, substância usada para endurecer plásticos e encontrada em embalagens de bebidas e alimentos). Over the last 40 years, only a handful of chemicals—e.g. lead, POPs (p.ex. PCB’s, DDT, chumbo), tributyltin, di(2-ethylhexyl)phthalate, nonylphenol and chlorpyrifos—have been banned in many countries, and sometimes these bans concern specific uses only. Nonetheless, there have been clear benefits for human and wildlife health from the declining use of these chemicals. PRINCIPAIS PREOCUPAÇÕES • Human and wildlife health depends on the ability to reproduce and develop normally. This is not possible without a healthy endocrine system. • Three strands of evidence fuel concerns over endocrine disruptors: ◦ The high incidence and the increasing trends of many endocrine-related disorders in humans; ◦ Observations of endocrine-related effects in wildlife populations; ◦ The identification of chemicals with endocrine disrupting properties linked to disease outcomes in laboratory studies. • Many endocrine-related diseases and disorders are on the rise. ◦ Large proportions (up to 40%) of young men in some countries have low semen quality, which reduces their ability to father children. ◦ The incidence of genital malformations, such as non-descending testes (cryptorchidisms) and penile malformations (hypospadias), in baby boys has increased over time or levelled off at unfavourably high rates. ◦ The incidence of adverse pregnancy outcomes, such as preterm birth and low birth weight, has increased in many countries. ◦ Neurobehavioural disorders associated with thyroid disruption affect a high proportion of children in some countries and have increased over past decades. ◦ Global rates of endocrine-related cancers (breast, endometrial, ovarian, prostate, testicular and thyroid) have been increasing over the past 40–50 years. ◦ There is a trend towards earlier onset of breast development in young girls in all countries where this has been studied. This is a risk factor for breast cancer. ◦ The prevalence of obesity and type 2 diabetes has dramatically increased worldwide over the last 40 years. WHO estimates that 1.5 billion adults worldwide are overweight or obese and that the number with type 2 diabetes increased from 153 million to 347 million between 1980 and 2008. • Close to 800 chemicals are known or suspected to be capable of interfering with hormone receptors, hormone synthesis or hormone conversion. However, only a small fraction of these chemicals have been investigated in tests capable of identifying overt endocrine effects in intact organisms. ◦ The vast majority of chemicals in current comercial use have not been tested at all. ◦ This lack of data introduces significant uncertainties about the true extent of risks from chemicals that potentially could disrupt the endocrine system. • Human and wildlife populations all over the world are exposed to EDCs. ◦ There is global transport of many known and potential EDCs through natural processes as well as through commerce, leading to worldwide exposure. ◦ Unlike 10 years ago, we now know that humans and wildlife are exposed to far more EDCs than just those that are persistent organic pollutants (POPs). ◦ Levels of some newer POPs in humans and wildlife are still increasing, and there is also exposure to less persistent and less bioaccumulative, but ubiquitous, chemicals. ◦ New sources of human exposure to EDCs and potential EDCs, in addition to food and drinkingwater, have been identified. ◦ Children can have higher exposures to chemicals compared with adults—for example, through their hand-to-mouth activity and higher metabolic rate. • The speed with which the increases in disease incidence have occurred in recent decades rules out genetic factors as the sole plausible explanation. Environmental and other non-genetic factors, including nutrition, age of mother, viral diseases and chemical exposures, are also at play, but are difficult to identify. Despite these difficulties, some associations have become apparent: ◦ Non-descended testes in young boys are linked with exposure to diethylstilbestrol (DES) and polybrominated diphenyl ethers (PBDEs) and with occupational pesticide exposure during pregnancy. Recent evidence also shows links with the painkiller paracetamol. However, there is little to suggest that polychlorinated biphenyls (PCBs) or dichlorodiphenyldichloroethylene (DDE) and dichlorodiphenyltrichloroethane (DDT) are associated with cryptorchidism. ◦ High exposures to polychlorinated dioxins and certain PCBs (in women who lack some detoxifying enzymes) are risk factors in breast cancer. Although exposure to natural and synthetic estrogens is associated with breast cancer, similar evidence linking estrogenic environmental chemicals with the disease is not available. ◦ Prostate cancer risks are related to occupational exposures to pesticides (of an unidentified nature), to some PCBs and to arsenic. Cadmium exposure has been linked with prostate cancer in some, but not all, epidemiological studies, although the associations are weak. ◦ Developmental neurotoxicity with negative impacts on brain development is linked with PCBs. Attention deficit/hyperactivity disorder (ADHD) is overrepresented in populations with elevated exposure to organophosphate pesticides. Other chemicals have not been investigated. ◦ An excess risk of thyroid cancer was observed among pesticide applicators and their wives, although the nature of the pesticides involved was not defined. • Significant knowledge gaps exist as to associations between exposures to EDCs and other endocrine diseases, as follows: ◦ There is very little epidemiological evidence to link EDC exposure with adverse pregnancy outcomes, early onset of breast development, obesity or diabetes. ◦ There is almost no information about associations between EDC exposure and endometrial or ovarian cancer. ◦ High accidental exposures to PCBs during fetal development or to dioxins in childhood increase the risk of reduced semen quality in adulthood. With the exception of these studies, there are no data sets that include information about fetal EDC exposures and adult measures of semen quality. ◦ No studies exist that explore the potential link between fetal exposure to EDCs and the risk of testicular cancer occurring 20–40 years later. • Numerous laboratory studies support the idea that chemical exposures contribute to endocrine disorders in humans and wildlife. The most sensitive window of exposure to EDCs is during critical periods of development, such as during fetal development and puberty. ◦ Developmental exposures can cause changes that, while not evident as birth defects, can induce permanent changes that lead to increased incidence of diseases throughout life. ◦ These insights from endocrine disruptor research in animals have an impact on current practice in toxicological testing and screening. Instead of solely studying effects of exposures in adulthood, the effects of exposures during sensitive windows in fetal development, perinatal life, childhood and puberty require careful scrutiny. • Worldwide, there has been a failure to adequately address the underlying environmental causes of trends in endocrine diseases and disorders. ◦ Health-care systems do not have mechanisms in place to address the contribution of environmental risk factors to endocrine disorders. The benefits that can be reaped by adopting primary preventive measures for dealing with these diseases and disorders have remained largely unrealized. • Wildlife populations have been affected by endocrine disruption, with negative impacts on growth and reproduction. These effects are widespread and have been due primarily to POPs. Bans of these chemicals have reduced exposure and led to recovery of some populations. ◦ It is therefore plausible that additional EDCs, which have been increasing in the environment and are of recent concern, are contributing to current population declines in wildlife species. Wildlife populations that are also challenged by other environmental stressors are particularly vulnerable to EDC exposures. • Internationally agreed and validated test methods for the identification of endocrine disruptors capture only a limited range of the known spectrum of endocrine disrupting effects. This increases the likelihood that harmful effects in humans and wildlife are being overlooked. ◦ For many endocrine disrupting effects, agreed and validated test methods do not exist, although scientific tools and laboratory methods are available. ◦ For a large range of human health effects, such as female reproductive disorders and hormonal cancers, there are no viable laboratory models. This seriously hampers progress in understanding the full scale of risks. • Disease risk due to EDCs may be significantly underestimated. ◦ A focus on linking one EDC to one disease severely underestimates the disease risk from mixtures of EDCs. We know that humans and wildlife are simultaneously exposed to many EDCs; thus, the measurement of the linkage between exposure to mixtures of EDCs and disease or dysfunction is more physiologically relevant. In addition, it is likely that exposure to a single EDC may cause disease syndromes or multiple diseases, an area that has not been adequately studied. • An important focus should be on reducing exposures by a variety of mechanisms. Government actions to reduce exposures, while limited, have proven to be effective in specific cases (e.g. bans and restrictions on lead, chlorpyrifos, tributyltin, PCBs and some other POPs). This has contributed to decreases in the frequency of disorders in humans and wildlife. • Despite substantial advances in our understanding of EDCs, uncertainties and knowledge gaps still exist that are too important to ignore. These knowledge gaps hamper progress towards better protection of the public and wildlife. An integrated, coordinated international effort is needed to define the role of EDCs in current declines in human and wildlife health and in wildlife populations. 5. Why should we be concerned?—Human disease trends ♦ A significant increase in reproductive problems in some regions of the world over the last few decades points to a strong role for unidentified environmental factors in disease etiology. ♦ Incidences of endocrine cancers, illustrated by country or region in Figures 7 and 8 for testicular cancer and breast cancer, respectively, have also increased during the same period. ♦ In certain parts of the world, there has been a significant decrease in human fertility rates, which occurred during one generation. There is also a notable rise in the use of assisted reproductive services. ♦ An increasing number of chemicals to which all humans in industrialized areas are exposed have been shown to interfere with hormone synthesis, action or metabolism. ♦ Experimental animal studies or studies with cells grown in culture have shown that many of these chemicals can also interfere with the development and function of mammalian endocrine systems. In adults, EDC exposures have recently been linked with obesity (Figure 9), cardiovascular disease, diabetes and metabolic syndrome. Many of these diseases and disorders are increasing in incidence, some globally. The global health expenditure on diabetes alone was expected to a total of at least 376 billion USD in 2010 and rise to US$ 490 billion in 2030—reaching 12% of all per capita health-care expenditures (Zhang et al., 2010). There are other trends of concern in human paediatric health. For example, some EDCs can interact with the thyroid system in animals and humans. Normal thyroid function is very important for normal brain development, particularly during pregnancy and after birth. EDC exposures have been linked with increased rates of neurobehavioural disorders, including dyslexia, mental retardation, ADHD and autism. In many countries, these types of disorder now affect 5.10% of babies born (http://www.medscape.org/viewarticle/547415_2); autism spectrum disorders now occur at a rate that approaches 1% (http://www.cdc.gov/ncbddd/autism/addm.html). The prevalence of paediatric asthma has more than doubled over the past 20 years and is now the leading cause of child hospitalizations and school absenteeism. Certain birth defects, such as those of the male reproductive organs (e.g. failure of the testes to descend into the scrotum), are on the rise. The incidences of paediatric leukaemia and brain cancer have risen, as has the incidence of testicular cancer. These are stark health statistics. All of these complex non communicable diseases have both a genetic and an environmental component, and, since the increases in incidence and prevalence cannot be due solely to genetics, it is important to focus on understanding the contribution of the environment to these chronic disease trends in humans. It has been estimated that as much as 24% of human diseases and disorders are at least in part due to environmental factors (Prüss-Üstün & Corvalán, 2006). It is a challenge to identify these factors, but there is also a tremendous opportunity to improve human health by improving elements of the environment that have an impact on public health. The recognition of these challenges and opportunities, along with the fact that many of the most prevalent diseases are associated with the endocrine system, has led to a focus on EDCs. Information on Chemicals in Electronic Products - A study of needs, gaps, obstacles and solutions to provide and access information on chemicals in electronic products (Main Authors: Nardono Nimpuno, ChemSec, Sweden and Caroline Scruggs, Stanford University, United States), TemaNord 2011 Tabell 2.4. Hazardous substances in specific materials and components of electrical equipment Printed circuit boards In printed circuit boards, cadmium occurs in certain components. Other hazardous metals such as chromium, lead, mercury, beryllium, zinc and nickel may are also be present. Brominated flame retardants and antimony trioxide are often used Liquid crystal displays, LCDs LCDs used in mobile phones and flat screen computer monitors may contain mercury. Cathode ray tubes, CRTs - Lead in the cone glass and cadmium/zinc/yttrium sulphide in the fluorescent coating. Batteries Heavy metals such as lead, mercury and cadmium are present in certain batteries. Plastic casings Plastics often contain halogenated flame retardants, many of which are hazardous. Also, combustion of the plastics and halogenated flame retardants can produce toxic substances. In addition, Antimony is often added to enhance flame retardancy Components, such as switches Mercury is used in fluorescent lamps, and has historically been used in thermostats, sensors, relays and switches, for example, on printed circuit boards Solder Can contain lead, tin and other metals. Internal and External Wiring Wiring is often coated in PVC which commonly contains numerous additives, including heavy metal compounds and softeners such as phthalates. Combustion of PVC can produce toxic substances. Semiconductors The semiconductor industry uses brominated flame retardants in the plastic encapsulation material Source: Adapted from Cui, J., Forsberg E. 2003 Workers, consumers and communities are exposed to chemicals in consumer electronics throughout their life cycle, from manufacture through use and disposal. The emphasis in discussions on health and environmental impacts from electronics is usually on the end-of-life phase, in particular during informal waste management. However, problems occur during the production stages as well, but information on these chemicals and their health impacts are scarce at best Studies have demonstrated high exposure to carcinogens and reproductive toxicants during production, including solvents, heavy metals and epoxy resins among electronics workers,28 and increased rates of spontaneous abortion and birth defects among women working in semiconductor fabrication.29 In addition, several studies over the past two decades have shown that electronics workers have a significantly elevated risk of lung, pharyngeal, nasal, breast, bladder, and brain cancers.30 Communities located near semiconductor manufacturing have suffered health impacts from direct contamination of their environment. Studies have been looking at the link between solvents and other chemicals leaked from semiconductor manufacturing plants in San Jose, California and increased rates of spontaneous abortions and congenital malformations among infants exposed during pregnancy.31 3.2 Exposure to chemicals in the use phase In addition, evidence is growing that exposure to (hazardous) chemicals also occur during the use-phase of electronics. Sampling of household dust indicates that levels of dioxins and furans in indoor environments is increasing. Studies looking at house dust and office dust in Japan found high levels of polybrominated dibenzofurans (PBDFs) in these environments. 32 ────────────────────────── 27 This study does not go deeper into the issue of problems associated with the use of chemicals in producing electronics. For more on the issue, see e.g. the Silicon Valley Toxics Coalition http://svtc.org/ 28 Alexander, R 29 Gray, 1993; Corn et al., 1993; Correa et al. 1996; LaDou et al. 1998 30 Beall et al. 1996; Bailar et al., 2000; Clapp 2006 31 Rudolph et al. 1986 36 Information on Chemicals in Electronic Products The authors found a correlation between polybrominated diphenylethers (PBDEs), and PBDFs and concluded that the PBDFs are a degradation product of PBDEs.33 The connection to electronics present in these environments cannot be ruled out. Other studies have looked at the debromination of flame retardants such as decabromodiphenylether, DecaBDE, a flame retardant used in a wide range of applications including electronics. For example, one study looked at the formation of PBDFs in flameretarded plastics exposed to normal sunlight.34 The researchers found that in high-impact polystyrene, HIPS, containing DecaBDE, the PBDF concentration increased by about 40 times after 1 week of exposure. Also, in TV casings with DecaBDE, PBDF concentrations increased continuously during the experiment. The researchers concluded that more attention should be paid to the fact that PBDFs are formed by sunlight exposure during normal use as well as disposal/recycling processes of flame-retarded consumer products.35 In addition, high levels of polybrominated dibenzodioxins (PBDDs) and polybrominated dibenzofurans (PBDFs) have been found in plastic TV housing, demonstrating the presence of dioxins and furans in the usephase of products containing plastics with brominated flame retardants.36 It is very likely that a significant share of the exposure described above comes from the presence and use of consumer electronics. Such findings raise concerns for risks during the use phase as well as in waste-management. Industry-wide initiatives have been set up which are international in their scope.These include the Joint Industry Guide (JIG), the International Electrotechnical Commission (IEC) material declaration standards and the Global Product Strategy (GPS) chemicals portal. IEC is developing a material declaration standard that is based on the JIG and the IPC data exchange format The chemicals or chemical classes most commonly mentioned by company representatives as being of concern in their products were: lead, mercury, cadmium, hexavalent chromium, brominated and chlorinated flame-retardants, and PVC Greening Consumer Electronics – moving away from bromine and chlorinechemsec, 2009 Of part icular concern within the electronics sector is the widespread use of bromine- and chlorine-based compounds in many different electronic applications. High volume uses of bromine and chlorine in flame retardants and plastic resins like polyvinyl chloride (PVC) gained worldwide attention when scientific studies documented their link to the formation of dioxin, one of the most toxic chemicals synthesized. Dioxins and other harmful chemicals are released into the environment during the burning and smelting of electronic waste. Even the most sophisticated incineration facilities generate low levels of dioxin, but the most significant dioxin contribution occurs in developing countries whose facilities are not designed to handle toxic materials. Som e of the unintentionally produced compounds are highly toxic, endocrine disrupting, and persistent, and are banned by the Stockholm Convention on Persistent Organic Pollutants (a treaty signed by 152 national governments). Component or material types that may contain bromine or chlorine: • Printed circuit board laminates • Flexible printed circuit boards • Connectors • Structural plastic parts • Integrated circuits or other electrical componentes with plastic packages or coatings • Cable insulators, over-molds, heat shrink tubes, and strain reliefs • Fan impellers • Optical films • Gaskets • Labels, insulators, and tapes • Paints, inks, and coatings • Adhesives • Rubbers and elastomers • Paper and corrugate • Solder flux • Glass Bromine- and chlorine-based compounds are used ubiquitously in the production of today’s modern electronic products as flame retardants, solvents, dyes, adhesives, and plastic resins. The largest uses of compounds containing bromine and chlorine are brominated flame retardants (BFR s), added to plastics to inhibit fire, and polyvinyl chloride (PVC) plastics, an inherently flame-resistant plastic resin. It is estimated that hundreds of different chlorinated and brominated flame retardants are currently on the market. The use of flame retardants is based on national fire safety standards, which vary from country to country. Many electronics manufacturers have opted for global compliance with fire safety standards set by the Underwriters Laboratories (UL), the world’s largest, not-for-profit product safety testing and certification organization. To satisfy fire safety standards, very high concentrations – generally 50,000 to 300,000 parts per million (ppm) or 5% to 30% – of BFR s must be used in plastics to effectively impede fires. The most common brominated flame retardant used in components for electronic products, such as printed circuit boards (PCBs), is tetrabromobisphenol A (TBBPA). Prior to the implementation of the European Union’s Restriction of Hazardous Substances (RoHS) directive, polybromodiphenyl ethers (PBDE s), and polybrominated biphenyls (PBBs) were sometimes used to flam e retard electronics. New restrictions under Europe’s chemical policy initiative, REAC H (Registration, Evaluation, and Authorization of Chemicals), appear likely to be applied to a third flam e retardant used in the electronics sector, hexabromocyclododecane (HBCD ). The predominant use of chlorine in electronics has been in PVC plastics. Most internal and external cables use PVC to insulate copper wires. Human health and environmental concerns about exposure to plastic additives used in PVC, such as lead, cadmium, and phthalates, as well as dioxin formation during the combustion of PVC components, triggered industry-wide efforts to replace PVC use in wire and cables. The major challenge has been developing alternative resins, that meet safety standards that in some instances were only written to specify PVC resins. To further complicate the situation, these safety standards vary geographically, forcing companies to use and get approval for multiple alternatives that comply with the different regional standards. Smaller concentrations of bromine and chlorine are used in a wide variety of applications other than flame retardants and PVC. Most manufacturers have focused on restricting the use of certain BFR applications and PVC, while others are restricting all uses of brominated and chlorinated substances. This has led to the development of standards that stipulate the requirem ents for officially defining components as “halogen-free,” “low-halogen,” “bromine-free,” or “chlorine-free.” Compounds that contain organic bromine and chlorine tend to be particularly likely to bioaccumulate, be persistent and/or toxic – or to degrade in the environment into new brominated or chlorinated organic compounds with these characteristics.1, 2, 3 As they accumulate over time, these organo-halogen compounds can become widespread pollutants in air, water, soil, and sediment, where they are increasingly ingested by humans and animals. It is also important to note that inorganic forms of these chemicals can lead to the formation of dioxin and other problematic chemicals, particularly when they are mixed with organic matter. PBB, PBDE s, PVC & DEHP/BBP/DBP, SCCP & MCCP, TBBPA, HBCDD são precursores de formação de dioxinas Chlorinated dioxins and furans can cause severe health problems8, including: • Cancer4 • E ndocrine disruption9 • E ndometriosis10, 11 • Neurological damage12 • Birth defects and impaired child development13, 14 • R eproductive system damage15, 16 • Immune system damage17 Because dioxins and furans break down slowly, they endure in the environment for long periods of time.18,19 Like many organohalogens, they bioaccumulate in animals’ fatty tissue. The highest concentrations are found in animals at the top of the food chain, including humans. Linda Birnbaum, a leading Science expert on BFR s and dioxins, led the US EPA’s 1994 dioxin assessment process, which concluded that for certain dioxins there was no safe level of exposure for humans.20 Most of what we know about dioxins and furans is the result of the study of one particular dioxin: 2,3,7,8 tetrachlorodibenzo-p-dioxin (TCDD ), which is a developmental toxicant that causes skeletal deformities, kidney defects, and weakened immune responses in the offspring of animals exposed to it during pregnancy. The compound is also associated with some cancers and other health effects, including immune system alterations and skin lesions. Additionally, studies indicate many of the hundreds of other dioxins and furans are likely to cause similar health effects.21 Dioxins and furans concentrate in breast milk so that human infants now receive doses that are orders of magnitude greater than that endured by the average adult.22 Such exposure to newborns is of great concern because it occurs at their most vulnerable stage of development. In Guiyu, China, an area infamous for its informal electronics recycling activities, the World Health Organization estimates that the daily intake of dioxins and furans by breast-fed infants exceeds guidelines by 11 to 25 times.23 Other halogens used in electronics, such as the TBBPA and HBCD flame retardants, have also been shown to concentrate in breast milk24, as well as in human and animal fat.25 In 2007, the highest levels of chlorinated dioxins and furans ever reported in the atmosphere were found in the air over Guiyu.26 Dioxin production is a worldwide concern due to the persistent organic pollutants’ ability to travel throughout the globe. In many cases polluted air travels towards the poles, but it is sometimes carried on the trade winds from Asia to North America.27 In addition to chlorinated dioxins and furans, two other forms of dioxins and furans can be formed from the combustion of electronics products: brominated and mixed chloro-brom o dioxins and furans.28 Although neither of these other groups of halogenated dioxins and furans has been as well studied as their chlorinated analogs, studies indicate that both brominated and mixed halogenated dioxins and furans are at least of equal concern.29 It is now suspected that thousands of different mixed halogenated dioxin and furan compounds may be generated when electronics are burned. Muitos produtos químicos de uso doméstico e industrial que não foram devidamente testados podem ter efeitos sobre o sistema hormonal e causar problemas de saúde significativos, de acordo com um relatório das Nações Unidas divulgado nesta terça-feira (19). O relatório O Estado da Ciência dos químicos de desregulação endócrina, produzido em conjunto pelo Programa das Nações Unidas para o Meio Ambiente (PNUMA) e pela Organização Mundial da Saúde (OMS), destaca algumas associações entre a exposição a desreguladores endócrinos (EDC, na sigla em inglês) e problemas de saúde, como câncer de mama, de próstata e de tireoide, além de déficit de atenção e hiperatividade em crianças. Estudo da ONU/OMS SAICM recognizes that risk reduction measures need to be improved to prevent the adverse effects of chemicals on the health of children, pregnant women, fertile populations, the elderly, the poor, workers and other vulnerable groups and susceptible environments. It states that one measure to safeguard the health of women and children is the minimization of chemical exposures before conception and through gestation, infancy, childhood and adolescence. EDCs represent a challenge, as their effects depend on both the level and timing of exposure, being especially critical when exposure occurs during development. They have diverse applications, such as pesticides, flame retardants in different products, plastic additives and cosmetics, which may result in residues or contaminants in food and other products. Therefore, EDCs may be released from the products that contain them. “Precisamos urgentemente de mais pesquisas para obter uma imagem mais completa dos impactos sobre a saúde e o meio ambiente de desrugladores endócrinos”, afirmou a Diretora de Saúde Pública e Meio Ambiente da OMS, Maria Neira. “A ciência mais recente mostra que as comunidades em todo o mundo estão sendo expostas aos desreguladores endócrinos, e seus riscos associados.” Os EDCs podem entrar no meio ambiente através de despejos industriais e urbanos, escoamento agrícola e pela queima e liberação de resíduos. Alguns EDCs ocorrem naturalmente, enquanto as variedades sintéticas podem ser encontrados em pesticidas, produtos eletrônicos, produtos de higiene pessoal, cosméticos e aditivos ou contaminantes em alimentos. Além de afetar seres humanos, esses elementos também podem prejudicar a vida animal. “Os produtos químicos são cada vez mais parte da vida moderna e apoiam muitas economias nacionais, mas o manejo inapropriado de produtos químicos desafia o alcance das metas fundamentais de desenvolvimento sustentável para todos”, destacou o Diretor Executivo do PNUMA, Achim Steiner. ROHS - DIRETIVA 2011/65/UE DO PARLAMENTO EUROPEU E DO CONSELHO de 8 de Junho de 2011 relativa à restrição do uso de determinadas substâncias perigosas em equipamentos eléctricos e electrónicos (substitui versões anteriores, desde a primeira Diretiva 2002/95/CE do Parlamento Europeu e do Conselho, de 27 de Janeiro de 2003) Se aplica a: 1. Grandes electrodomésticos 2. Pequenos electrodomésticos 3. Equipamento informático e de telecomunicações 4. Equipamento de consumo 5. Equipamento de iluminação 6. Ferramentas eléctricas e electrónicas 7. Brinquedos e equipamento de desporto e lazer 8. Dispositivos médicos 9. Instrumentos de monitorização e controlo, incluindo instrumentos industriais de monitorização e controlo 10. Distribuidores automáticos 11. Outros EEE não incluídos em nenhuma das categorias acima. Os Estados-Membros asseguram que os EEE colocados no mercado, incluindo os cabos e as peças sobresselentes para a respectiva reparação, reutilização, actualização das funcionalidades ou melhoria da capacidade, não contenham as substâncias sujeitas à restrição a que se refere o n. o 1 do artigo 4. o e valores máximos de concentração ponderal tolerados em materiais homogéneos Chumbo (0,1 %) Mercúrio (0,1 %) Cádmio (0,01 %) Crómio hexavalente (0,1 %) Bifenilos polibromados (PBB) (0,1 %) Éteres difenílicos polibromados (PBDE) (0,1 %) a Comissão deve ponderar uma revisão, com base numa avaliação exaustiva, e a alteração da lista de substâncias sujeitas a restrição nos termos do anexo II antes de 22 de Julho de 2014, e de forma periódica A marcação CE deve ser aposta de modo visível, legível e indelével no EEE acabado ou na respectiva placa de identificação. Se a natureza do produto não o permitir ou justificar, a marcação CE deve ser aposta na embalagem ou nos documentos de acompanhamento. A marcação CE deve ser aposta antes de o EEE ser colocado no mercado. Reciclagem de lixo eletrônico chemsec A UNEP- Programa Ambiental das Nações Unidas estimou que mundialmente os consumidores compraram quase 900 milhões de telefones celulares em 2006, e acima de 1 bilhão em 2007. Uma parcela considerável destes produtos acaba sendo destinado inadequadamente a aterros domésticos de resíduos. Acima de 75% do resíduo eletrônico gerado na Europa e em torno de 80% do gerado nos Estados Unidos são destinados sem controle, sendo que uma boa parte deles é exportado para países em desenvolvimento, que muitas vezes são manuseados e destinados inadequadamente, com custos muito mais baixos (p.ex. é estimado que os custos de manuseio/reciclagem/destinação de computadores pessoais e telefones celulares são 10 vezes maiores nos Estados Unidos e na Comunidade Européia do que na India ou Nigeria). 1. Legislação Muitas das políticas e diretrizes legais sobre gestão de resíduos introduzidas nos últimos anos são baseados no princípio da responsabilidade extendida do produtor - EPR. The idea behind this principle is that manufacturers have a responsibility for their products, and the environmental impacts related with these products, which goes beyond the production stage. The EPR principle stresses especially manufacturers’ responsibility for the endof-life treatment of their products. This responsibility can manifest itself in different ways, but it usually includes either a physical responsibility to take back the product after its use, or a financial responsibility to pay for recycling or waste treatment carried out by another company. The producer responsibility can also include a requirement for the manufacturer to disclose information needed for safe use, handling, recycling and disposal. This informative responsibility makes producers responsible for providing information on the product or its effects at various stages of its life cycle and could thus include CiP information. There is a double rationale behind the EPR principle. The first is related with financing and the second with product re-design. Traditionally, waste disposal and recycling has been paid for with tax money. By regulating that a certain kind of end-of-life treatment should be carried out and letting the producers pay for the establishment and operation of such a system, the costs will be internalised in line with the polluterpays principle. Some of these costs will then likely be carried by consumers through increased product prices. This is the direct effect of na EPRbased system. In the longer term, if manufacturers have to carry the financial burden for endof-life treatment, they will have an incentive to modify the design of their products so that they are easier to recycle and the materials used can generate more income as secondary resources. Prazo SMA 13/12/11 2. Movimentos para implementação de coleta e reciclagem 3. Tendências Substâncias perigosas contidas nos equipamentos eletro-eletrônicos chemsec As substâncias mais procuradas são as consideradas perigosas, as “PTB’s” (Persistentes, Bioacumuláveis ou Tóxicas), mPmB (muito Persistentes e muito Bioacumuláveis), mutagênicas, tóxicas para a reprodução, As substâncias classificadas como muito tóxicas para organismos aquáticos e causadores de efeitos adversos em longo prazo no meio aquático. Computadores e telefones celulares podem conter acima de 1000 substâncias diferentes. As principais substâncias perigosas que podem ser encontradas em produtos eletrônicos são: chumbo, mercúrio, cádmio, zinco, cromo, berílio, niquel, retardantes de chama bromados e halogenados, trióxido de antimônio, estanho, PVC e ftalatos. Adicionalmente, eles contém metais valiosos passíveis de recuperação, como ouro e cobre. Outros estudos tem demonstrado potencial liberação de dibenzofuranos polibromados (PBDFs) em seu uso, que são produtos de degradação éteres difenílicos polibromados (PBDEs), comumente usados como retardante de chamas em electrônicos. 1. Legislação Nos último anos, foi desenvolvido um grande número de iniciativas legais sobre químicos em produtos eletro-eletrônicos, bem como no seu tratamento no fim-de-linha. As mais notáveis foram definidas pela Comunidade Européia, consistindo das Diretivas para Restrição de Substâncias Perigosas – RoHS, de Resíduos de Equipamentos Eletro-eletrônicos – WEEE, e da mais abrangente Diretiva de Registro, Avaliação, Autorização e Restrição de Químicos – REACH. O REACH (aprovado pelo Regulamento 1.907/2006 do Parlamento Europeu e do Conselho em 18/12/06, entrou em vigor em 01/06/07) é o regulamento europeu relativo ao registro, à avaliação, à autorização e à restrição das substâncias e misturas químicas, com o objetivo de garantir o seu uso seguro, elevando o nível de proteção da saúde humana e do ambiente. Esse regulamento supõe uma reforma total do marco regulatório sobre substâncias e misturas químicas dentro da União Européia. Para isso, introduz a obrigação de realizar um registro de todas as substâncias químicas comercializadas dentro do território da União Européia, e cujo requisito de informação aumenta com o volume do produto químico registrado. Caso necessário, propor-se-ão medidas de restrição para determinadas substâncias de grande preocupação (de 1500 a 2000 substâncias), como as carcinogênicas; mutagênicas; tóxicas à reprodução; persistentes, bioacumulativas & tóxicas (PBT), e de muito grande preocupação (de 25 a 30 substâncias), como as muito persistentes & muito bioacumulativas (vPvB), e se promoverá sua substituição sempre que existam alternativas viáveis. Em princípio, o REACH afeta todas as substâncias químicas, a não ser as excluídas de forma explícita, tais como as substâncias radioativas, transporte de substâncias perigosas e resíduos (a menos que sejam importados ou comercializados). NORMATIVA EUROPÉIA SOBRE SUSTÂNCIAS E MISTURAS QUÍMICAS •DIRETIVA 2006/12/CE do Parlamento Europeu e do Conselho, de 5 de abril de 2006, relativa a resíduos (DOUE L 114 de 27/04/2006); Estas diretizes causaram grande impacto no modo como os produtos eletrônicos são projetados, coletados e tratados na fase de pós-uso, e como a informação sobre substâncias perigosas são geradas e compartilhadas. A partir desta estrutura europeia, outra regiões e países como os Estados Unidos, a Coréia do Sul, China e Japão tem desenvolvido esforços legais na mesma direção: . EUA - TSCA - Toxic Substance Control Act . IECSC – China - Inventory of Existing Chemical Substances Produced or Imported in China . MITI – Japão - Existing and New Chemical Substances (ENCS); Priority Assessment Chemical Substances (PACS) . Coréia do Sul - ECL – Existing Chemicals List Iniciativas abrangentes do setor industrial tem sido estabelecidas nesta mesma linha, tais como: - Guia Conjunto da Indústria Eletrônica (JIG) elaborado por Associações de Indústrias dos Estados Unidos (EIA), Japão (JGPSSI) e Europa (EICTA), com o objetivo de ganhar informação sobre a composição (química) dos produtos e subpartes incorporadas aos produtos eletroeletrônicos - norma de declaração de materiais da IEC; - Estratégia Global de Produtos (GPS) da Indústria Química. Falar também da SIN list – ver site da chemsec electronics -> SIN List: 378 Substances, composta de 311 CMR substances; 17 PBT/vPvB, Substances; 50 Equivalent concern Substances JIG: anexo E traz tabela contendo a legislação Européia e de alguns países da CE, do Japão, dos Estados Unidos e os principais usos das substâncias químicas perigosas Trazer para cá a tabela SAICM project on Hazardous Substances within the Life Cycle of Electrical and Electronic Products. Falar que diversas substâncias são procuradas no mundo inteiro, e que diversos países adotaram legislação restritiva www.cas.org DSL: NDSL (canadá) PBT - Persistent bioaccumulative toxic chemical TSCA (USA) - Toxic Substance http://www.epa.gov/oppt/tsca8e/ Control Act - CLP (CE) – classification, labeling and packaging regulation MITI – japão IECSC – China - Inventory of Existing Chemical Substances Produced or Imported in China http://www.crc-mep.org.cn/iecscweb/IECSC.aspx?La=1 – similar ao reach ECL – coréia PICCS – phillipinas NICNAS – National Industrial Chemicals Notification and Assessment Scheme - austrália - http://www.nicnas.gov.au/ NZIC - New Zealand Institute of Chemistry – nova zelândia - New Zealand Inventory of Chemicals (NCIoC) Reach - CE Regulated Chemicals Information A wealth of regulatory information is available online in the CHEMLIST database. The experts at CAS are relied on to: Build and maintain the TSCA inventory for the EPA Check and verify all substance information and provide quality assurance for each substance Conduct a customized search for you Provide CA index names and CASRNs for PMN submissions to the US EPA or other government agencies For some commonly asked questions, select an inventory list below. United States U.S. Toxic Substance Act (TSCA) Superfund Amendment Reauthorization Act Title III (SARA Title III) California Proposition 65 (California Prop 65) Department of Transportation (DOT) Toxic Release Inventory (TRI) Canada Canadian Domestic Substances List (DSL) Canadian Non-Domestic Substances List (NDSL) National Pollutant Release Inventory (NPRI) Significant New Activity Notice (SNAc) o o o o o Europe European Inventory of Existing Commercial Chemical Substances (EINECS) European List of Notified Chemical Substances (ELINCS) No-Longer Polymers List (NLP) REACH List of Pre-Registered Substances Candidate List of Substances of Very High Concern (SVHC) for Authorization Annex IV: Exempt from Registration Annex XIV: Substances Subject to Authorization Annex XVII: Dangerous Substances and Preparations Korea Korean Existing Chemicals List (ECL/KECL) Japan Japanese Existing and New Chemical Substances (ENCS) Japanese Priority Assessment Chemical Substances (PACS) Australia Australian Inventory of Chemical Substances (AICS) Philippines Philippines Inventory of Chemicals and Chemical Substances (PICCS) Taiwan List of Toxic Chemical Substances regulated under the Taiwan Toxic Chemical Substances Control Act of 1986 (Taiwan) Israel 2001 proposed list of chemical substances to be regulated under the Israel Hazardous Substances Law and Regulations List (Israel) New Zealand New Zealand Inventory of Chemicals (NCIoC) 4.3.1 The European Union Although neither specifically focused on products nor any particular sector, the European Union REACH regulation on chemicals has since its adoption in 2007 had a global impact, on legislation in other part of the world as well as on how communication on chemicals and chemicalscontaining products is perceived, carried out and handled. Furthermore, REACH identifies and controls the use of high concern chemicals, through its Authorisation system as well as through Restrictions. REACH has also established provisions on data sharing, through its publicly accessible database and mandatory flow of information on the presence of chemicals in the supply chain as well as the intrinsic properties of these.72 With regards to information on Chemicals in Products, REACH introduces two types of information requirements. First, there are requirements on manufacturers and importers to in certain cases make a notification or registration. If a product (or “article” in REACH terminology) contains any chemical that is to be intentionally released from the product, it has to be registered with the European Chemicals Agency (ECHA). If the chemical is not to be intentionally released but is identified as of high concern (in REACH a “Substance of Very High Concern” or SVHC) and has a concentration above 0.1%, then ECHA has to be notified. ECHA may then also require the chemicals to be registered. This is only necessary for chemicals that are produced or imported in volumes exceeding 1 tonne per producer or importer per year. There are other additional criteria which exempt chemicals from these requirements. Secondly, there are requirements on suppliers to give information to professional customers (“recipients”) and on request to consumers (the “right to know”) about any SVHCs which constitute more than 0.1% of the product.. The information must be sufficient to allow safe use and as a minimum the name of the SVHC has to be given. There are neither volume limits for nor exemptions from these requirements. These provisions have an impact on the flow of information on high concern chemicals from producers/importers to actors further down the product chain. They also apply to products from recycled materials. In order to manage the end-of-life phase of products, European countries and Japan have been at the forefront in introducing waste regulations based on EPR. As part of a legislative initiative to solve the problem of huge amounts of toxic e-waste, the EU Waste Electrical and Electronic Equipment Directive, WEEE, imposes EPR for a broad range of electronic products. It sets collection, treatment and recycling targets for electronic waste and places the financial responsibility for carrying the costs for recycling on the manufacturers and importers. It also mandates producers to disclose information needed for end-of-life treatment. Producers must provide reuse and treatment information for each type of new EEE within one year after the product is put on the market. The information shall identify, as far as it is needed by reuse treatment and recycling centres, the different EEE componentes and materials, as well as the location of dangerous substances and preparations in the product. Also, the WEEE symbol must be placed on concerned EEE, informing consumers not to dispose of the product as unsorted municipal waste but to collect it separately. Although WEEE requires information sharing with recyclers, it has so far not been a priority for the public authorities of the EU countries to specify how this information disclosure should be carried out and what information should be included. The regulators seem to assume that there is a demand for information from the recycling industry and that requests from the recycling companies will determine what information is made available and in what format.73 Manufacturers have taken different approaches to fulfilling the information requirement. Some of them have developed datasheets with recycling information and made these sheets available on their websites. In some cases these sheets also include details on the recommended disassembly process, supported by photos. In a few cases, the recyclers need to submit a registration form in order to get a user ID and password to access the information. There are also manufacturers who request that recyclers contact them by email.74 Compared with the Japanese marking systems for home appliances, the European systems in general contain less information. In particular, detailed information on plastic components (additives and the use of recycled polymers) and on hazardous metals in circuit boards is lacking. Closely linked to WEEE, the Restriction of Hazardous Substances Directive(RoHS), was adopted in February 2003 by the European Union. This directive restricts the use of six hazardous substances (lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers (PBDEs) in the manufacture of various types of electronics. 4.3.2 The United States In the US there is no federal law mandating recycling of electronics or to make the producers responsible for the end-of-life treatment of their products. More than a dozen individual states have recently introduced recycling regulations, but these regulations differ by state and the producers are facing a patchwork of requirements. None of these state regulations require producers to provide recyclers with product information. Certification systems for recyclers such as the Responsible Recycle (R2) Practices and the Esteward Certification program have been introduced to ensure the responsible recycling of electrical equipment and electronic devices through the certification of reliable recyclers and the promotion of sound recycling. To comply, recyclers will have to increase their efforts to stay informed on the changes in composition of products and to develop appropriate and safe treatment methods. The Responsible Recycling (R2) Practices is a set of guidelines for accredited certification programs to assess electronics recyclers’ environmental, worker health and safety, and security practices. The voluntary R2 practices include general principles and specific practices for recyclers disassembling or reclaiming used electronics equipment including those electronics that are exported for refurbishment and recycling and also requires downstream tracking of materials.75 E-stewards sets up a system for responsible recycling for the whole recycling chain. It places restrictions on what waste and what hazardous material can go downstream. As part of the certification, the E-stewards recyclers must set up environmental management systems that also include occupational health. The aim of the system is to promote reuse of electronics and to prevent hazardous material from travelling downstream without appropriate management, e.g. from OECD to non-OECD countries. Estewards encourages as well as disallows certain recycling activities.76 Sara Westervelt at E-stewards explains: “Devices containing hazardous components must be properly tested and only fully functional devices are allowed for export to non-OECD countries. Devices containing hazardous substances are not allowed for e.g. shredding, unless the toxic components are properly removed.” The EPEAT standard, which currently covers only computers, requires information disclosure for safe end-of-life treatment. EPEAT allows purchasers to compare the environmental performance of products based on these criteria. EPEAT is quite widely used, not at least for public procurement, and it therefore has significant influence on the industry. Products registered in EPEAT must meet a core of 23 environmental performance criteria. They are then rated Gold, Silver or Bronze based on the percentage of a further 28 optional criteria which they meet. The requirements include the confirmation and elimination of parts containing hazardous substances, and the identification of plastic parts by marking them.77 Although established in the United States, EPEAT, R2 and E-Stewards are all international in their reach. 4.3.3 Japan Seguindo a introdução do WEEE, RoHS e REACH da Comunidade Européia, o Japão tem feito esforços para aumentar o controle de informações sobre as substâncias químicas nos produtos e para promover o eco-design de produtos, através da Política Integrada de Produtos, que considera o ciclo de vida dos produtos. Com respeito a equipamentos elétricos e dispositivos eletrônicos, the Japanese industry consortium Joint Article Management Promotion-Consortium, (JAMP), has developed an information system which facilitates the management of information on chemicals in the upstream part of products’ life cycles. In addition to MSDS, JAMP utilizes JAMP MSDSplus for the purpose of information control in the upstream and midstream processes concerning substances and preparations contained in the products. Article Information Sheets, AIS, are utilized for preparations in the downstream processes. The JAMP-Global Portal is being operated in order to share compiled chemical substance information among the upstream, midstream and downstream sides. A Iniciativa Japonesa de Padronização de Compras Verdes (JGPSSI), um membro regional do JIG (Joint Industry Guide), formulou as Diretrizes para a Gestão de Substâncias Químicas em Produtos, provendo métodos de compartilhamento de informação requeridas para conformidade com o REACH. To this end JGPSSI forms are promoted. Japanese manufacturers not only deal with the rules and regulations set by the EU, but also promote their own initiatives. In response to the Home Appliance Recycling Law, the Association for Home Appliance Recycling and other related organisations have established a system of assigning recycling marks that through labelling indicate the information on chemical substances used in the products and information on their disassembly, so that the disassembly process and resources recovery rate can be improved at the recycling stage. In response to the RoHS Directive, JIS established the J-Moss standard for the marking of chemical substances contained in electrical equipment and electronic devices. J-Moss communicates information from downstream of the supply chain to the consumption stage and then on to the recycling chain. It sets the control criteria for RoHS-specified hazardous substances (see paragraph on RoHS, above) contained in PCs, air conditioners and other targeted products. When the content of a specified substance in a product is at a level beyond the set criteria, a “containing” mark is stamped on the product and the manufacturer is obliged to provide on its website information on the parts containing the substance, the level of content, etc. O Japão tem uma legislação de reciclagem baseada no princípio de responsabilização pelo produtos, cobrindo computadores pessoais e grandes eletrodomésticos. These laws set recycling targets for each product category individually and require consumers and manufacturers to pay for collection and recycling. In contrast to the WEEE Directive, the Japanese EPR system does not include any requirement to disclose recycling information. However, unlike in Europe, many Japanese recycling companies are closely related to the manufacturers – in some cases they are owned by large industrial groups that also include electronics manufacturing firms. The Waste Data Sheet (WDS) is only utilised in the recycling chain. In principle, a WDS is produced by the waste generators and describes for waste handlers the properties of the waste, such as its corrosiveness, explosiveness, flammability, ecotoxicity, and other stability and reactivity properties. A WDS also describes the content of specified hazardous substances in waste (e.g. lithium, magnesium, sodium, copper and other metals, mercury, PCBs). The main characteristic of a WDS is that it is transported together with varying types of industrial waste, and provides detailed information to the receivers of the relevant waste. While information sharing concerning hazardous substances is promoted through JAMP, information on valuable substances, particularly gold, silver, indium and other expensive precious metals and rare metals, has not yet been included in the scope of information collection, even in the supply chain. Another shortcoming is that web-based databases concerning substances that are hazardous or have an environmental impact are only utilized in JAMP in the supply chain, and are not yet shared with consumers, recyclers or treatment businesses. In the case of recycling marks or J-Moss marks, which only include a limited number of chemical substances within their scope, it is considered feasible to implement marking or labelling for communicating information from the supply chain to the consumption stage, and then to the recycling chain. A Coréia do Sul introduziu recentemente legislação similar à Diretiva Européia WEEE, e está estudando formas de desenvolvimento da legislação sobre gestão de substâncias químicas baseada na legislaçãoEuropéia (REACH e RoHS). O governo também introduziu a Lei de Reciclagem de Recursos de Equipamento Eletroeletrônicos e Veículos em 2008, baseado no princípio da Responsabilização pelos produtos. Esta lei almeja um controle sistemático control de informações sobre substâncias valiosas e perigosas, pela redução de geração de resíduos de equipamentos elétricos, dispositivos eletrônicos e veículos, promovendo o projeto do produto que facilite a reciclagem, e reduzindo impacto ambiental. O sistema é chamado de Eco-Assurance System, EcoAS. Assim como Japão e Coréia do Sul, o governo chinês está promovendo o estabelecimento de legislação relativa a substâncias perigosas contidas nos produtos e poluição causada por produtos eletrônicos, como resposta ao REACH, RoHS e WEEE. 12. LINKS DE INTERESSE •Página da web de IUCLID5: http://ecbwbiu5.jrc.it/ •Página da web da OCDE: “Global Portal to information on Chemical Substances”: http://webnet3.oecd.org/echemportal/ •Página da web da ECHA: “European Chemicals Agency”: http://echa.europa.eu/ •Navegador REACH da ECHA: “European Chemicals Agency”: http://reach.jrc.it/navigator_en.htm •European Commission Enterprise and Industry – REACH: http://ec.europa.eu/enterprise/reach/index_en.htm •European Commission Environment Chemicals – REACH: http://ec.europa.eu/environment/chemicals/reach/reach_intro.htm •EUROPEAN CHEMICALS BUREAU – REACH: http://ecb.jrc.ec.europa.eu/reach/ •INFORMAÇÃO SOBRE O REACH Workshop CELEBRADO EM BRUXELAS EM 14 DE ABRIL: http://ec.europa.eu/enterprise/reach/events_en.htm 2. Substâncias perigosas contidas nos equipamentos eletro-eletrônicos Ver item 2.4 e tabela 2.4 do relatório chemsec 3. Tendências Legislação brasileira sobre responsabilização pelos produtos e sobre substâncias restritas 5.5.9 New standards allowing comparison of products on environmental and human health performance Standards allowing for comparison of electronics products’ environmental performance may incentivise more manufacturers to focus on the human health and environmental effects of every chemical chosen for their products. Standards for labels and information pertaining to energy efficiency currently exist for electronics products, allowing consumers to compare products and make choices according to their preferences. Similar types of standards could be created pertaining to chemicals, including information on recyclability, chemical toxicity, and lifecycle issues, all of which could be included on labels and used by consumers to compare products. Such a standard could help companies that prioritize health and environmental performance compete on such product characteristics and realise an advantage in the market. It would also clearly define health and environmental performance goals for companies that are not currently focused on such performance in their product design. A standard and labelling system that allows for comparison of products based on environmental impact of chemicals should also make it possible for companies to make economic arguments for use of environmentally preferred chemicals. The Green Chemistry Institute of the American Chemical Society, in partnership with the standards development organization NSF International, will soon introduce a new standard that represents a good first step in this direction. The standard will help companies reduce their use of hazardous chemicals and materials in their products and motivate industry to make choices resulting in reduced impact on the environment and human health. The standard would be voluntary, and companies could demonstrate their adherence to the standard through diferent levels of certification. 81 5.5.10 Regulations for ecolabels and “green” claims Greenwashing has become a significant problem, and regulations are needed to provide guidelines on ecodesign and to prevent companies from making misleading green claims. Product labels should not refer to a product’s compliance with legal requirements – this confuses consumers, since any product being sold should already be compliant with any relevant legal requirements. Ecolabels should strive to maintain credibility by ensuring that certified products meet high standards of excellence. The environmental or health significance of the certification should also be clearly represented to avoid misleading consumers and to allow them to use ecolabels as shortcuts to finding products with the features they desire.

Download