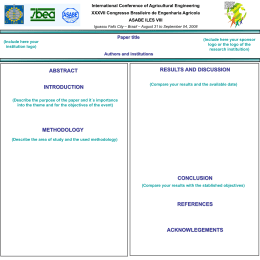

ADVANCED PRODUCTION SCHEDULING APPLIED TO DIFERENT LEVELS OF MASS CUSTOMIZATION INDUSTRIAL ENVIRONMENTS Author: Felipe Corrêa de Oliveira Supervisors: Paulo Martins, Co-Supervisor: Dinis Carvalho University of Minho School of Engineering Production & Systems Department [email protected] Conclusions Introduction After the growth and development of the Mass Production, the Mass Customization raised as a new trend on the industrial scene. Nowadays the organizations pursuit to deliver a big volume of customized products being profitable on their daily operations. Mass customization relates to the ability to provide individually designed products and services to every customer through high process flexibility and integration (Pine 1999). According to this new industrial environment, there are a lot of abilities and critical factors that helps companies on achieving this objectives. Depending on the level of mass customization they are offering, from standardized products (Mass Production) to totally customized products (Mass Customization), companies are implementing a lot of actions to be flexible and profitable. The Mass Customization System consists on the group of process and methodologies that supports a successful Mass Customization Strategy Implementation. One of the main actions to be implemented, Agile Manufacturing supported by an efficient Production Scheduling Model becames an important enabler for Mass Customization success. Mass Customization and Production SchedulingSystems After the recent bibliography investigation, the researcher concluded that: • Most of the Scheduling Models only supports specific industrial environments and conditions; •Most of the previews researches was under specific industrial environment conditions; •And finally, the development of a flexible scheduling model definition methodology, able to be applied on every production environment, was not described before. With this assumptions a simulation and testing model was conducted to develop and evaluate this method (Figure 1). Environment Production Strategy Market Product Results Scheduling Model Production Process Analysis Optimized Model Industry Condictions Yes OK? Research Agenda In order to develop a new flexible Production Planning System to deal with different levels of Mass Customization and different Industrial environments, first the author had to focus on investigating all the current production planning models actually available. Models like MRP (Plenert, 1999), Kanban (Jodlbauer & Huber, 2007), ConWip (Spearman & Hoop, 1991), DBR (Goldratt, 1990) and POLCA (Suri, 2002) were strongly analized to determinate how they behave submitted to different levels of Mass Customization and different combinations of market conditions, production process and product characteristics. The success of mass customization appears to be dependent on a flexible production system which depends on a flexible productions scheduling model also. Today the adoption of a model like this emerges as one of the success enablers for the mass customization strategy and on the other hand the other models are limited and unflexible. References No Mass Customization consists on deliver high customized products on high scale, with low cost and efficiency. Some authors describes more than one level of Mass Customization. These levels can be determined by the combination between Market Conditions, Production Process and Product Characteristics . The need to develop agile production systems and the actual technology available enforces the rapid Production Planning Systems evolution. According to the research development described on the previous sections is possible to have an idea about this innovative method proposed. Moreover, it is unquestionable the importance and usefulness of the proposed method to the success of companies in the search for an agile manufacturing system. Figure 1:Research Method This method consists on: First determine different industrial environments according to the possible combinations across market conditions, product characteristics and production process; second determine a Scheduling Model based on Fernandes (2007) dimensions of Production Scheduling models, named in his research as Work Load Control mechanism; third simulate the scenario using a simulation model develop by Melnyk & Ragatz (1989) and evaluate the results based on common production analysis metrics; and fourth, repeat this third step until achieve an optimal model. Research Status Now the author is facing the fourth step, trying to achieve an optimal model for each environment and developing a method to make this model specification automatic. Fernandes, N. O.; Contribuições para o Controlo da Actividade de Produção no Sector de Produção por Encomenda. Tese de Doutoramento em Engenharia de Produção e Sist emas(2007).Disponível www.repositorium.sdum.uminho.pt H. Jodlbauer; A. Huber; Service-level performance of MRP, Kanban, CONWIP and DBR due to parameter stability and environmental robustness. International Journal of Production Research, Vol 46, No. 8, 15 April 2008, 2179-2195 MELNYK, S. A.; RAGATZ, G. L. (1989)- Order review/release: research issues and perspectives. International Journal of Production Research. Vol. 27: nº 7 (1989), p. 1081-1096. Pine, J. (1999). Mass Customization: The New Frontier in Business Competition, Harvard Bussiness Press. Plenert G. (1999). "Focusing material requirements planning (MRP) towards perfomance." European Journal of Operational Research 119 (1999) 91-99 Spearman M.; Woodruff D.; Hoop W.; Conwip: a pull alternative to Kanban. International Journal of Production Research, 1990, vol. 28, no 5 SURI, R.; KRISHNAMURTHY, A. - How to Plan and Implement POLCA: a material control system for high-variety or customengineered products. Center for Quick Response Manufacturing. Madison: University of Wisconsin, 2003. Technical Report. Uma Escola a Reinventar o Futuro – Semana da Escola de Engenharia - 24 a 27 de Outubro de 2011

Baixar