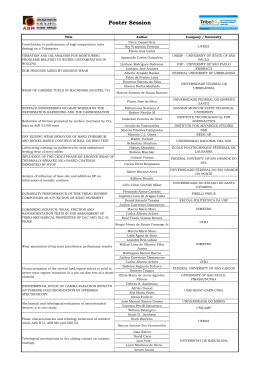

ANALYSIS OF NAPHTHENIC CORROSION BY ATOMIC FORCE MICROSCOPY Heloisa Pinto Dias1, Natwrie Seny Malta Almeida1,2, Ricardo Boldrini3, Pedro Vitor Dixini1,4, Luiz C. P. Almeida 1, Gabriela Vanini1, Eustáquio V. R. Castro1, Alexandre O. Gomes 5, Robson R. Moura5, Valdemar Lacerda Jr. 1, Boniek G. Vaz6, Wanderson Romão1,2 and Glória M de F Viégas Aquije1,2 1 Petroleomic and Forensic Laboratory, Department of Chemistry, Federal University of Espírito Santo, 29075-910, Vitória, ES, Brazil. 2 Federal Institute of Education, Science and Technology of Espírito Santo, 29106-010, Vila Velha, ES, Brazil. 3 Federal Institute of Education, Science and Technology of Espírito Santo, 29106-010, Vitória, ES, Brazil. 4 Federal Institute of Education, Science and Technology of Espírito Santo, 29106-010, Aracruz, ES, Brazil. 5 Petróleo Brasileiro S/A – PETROBRAS, CENPES, Rio de Janeiro, RJ, Brazil. 6 Chemistry Institute, Federal University of Goiás, 74001-970, Goiânia, GO, Brazil. Presenting author: Natwrie Seny Malta Almeida; [email protected] Naphthenic acids are considered primarily responsible for corrosion in the oil refining process [1], and if not properly monitored, the naphthenic corrosion can cause severe damage to the petrochemical industry [2]. The Atomic Force Microscopy (AFM) has also demonstrated be useful to in situ morphologic analysis on metals surface in a nanometric scale [3]. With objective to monitor the naphthenic corrosion on steel AISI 1020 and AISI 316, using the AFM as an analysis tool, this work was realized. The images were measured dry, using the AFM (WITec/ Wissenschaftliche Instrumente und Technologie GmbH®) in non-contact mode, with Si3N4 cantilever tips, nominal constant of 42N.m-1 and resonance frequency of ≈ 285 kHz, scan rates of 0.3-1.0 Hz and scan size of 5.000 to 10.000 nm. Oil samples treated at 350°C/6h, were brought in contact with carbon steel AISI 1020 for 15 days. The acidity of the original and products from oil heat treatment was monitored by TAN ESI (-) - FT-ICR-MS and corrosion on steel was monitored by AFM. The ESI (-) - FT-ICR MS showed that the O2 class, the major species detected were majority carbon number of C 25-C32 and DBE = 3. For treatment at 350°C/6h, there was a reduction of ~ 80% in the TAN. The results showed that AFM topography (Figure 1: A, B, C and D) of the steel surface exposed to the oil treated at 300°C/6h has higher effects of corrosion, since the pattern of measured by "peak-peak height" of the surface, indicated that the surface exposed to the oil 300°C/ 2h presents a number of irregularities (Figure 1C and D). The AISI 316 showed that the major classes were identified in the samples classes O 2 and N2. Regarding O2 class, the major species detected were majority of carbon number C 24 and C35 = 3 DBE and DBE and C29-C35 = 4. The AFM images, in different periods of time (0, 7, 14, 21, 28 and 36 days), showed that the interval for 14 days, the steel exposed to oil J, showed strong topographic changes from white, characterizing the onset of the corrosion process (Figure 2: G and H). This information is consistent with the Raman spectra that for this period of time the formation of goethite, hematite and magnetite were evidenced (data not shown). Topographical changes to the exposed steel to oil G could only be observed after 21 days of analysis by AFM (Figure 2: E and F). The AFM has detected a topographic profile much altered for the stell AISI 1020 when compared to steel AISI 316. The potential of the combination of two powerful analytical tools, ESI (-) FT-ICR MS, and AFM in the study both the chemical composition of acids naphthenic as its corrosive power, allowing involve the molecular composition of oil samples with its corrosive power of carbon steel. This fact evidences the importance of developing physical and chemical parameters based on data from AFM and FT-ICR to evaluate and monitor the extent and type of corrosion due to exposure time to the particular type of oil. Keywords: naphthenic acids, corrosion, ESI (-) - FT-ICR MS and AFM. Acknowledgements: FAPES, FAPEG, PETROBAS, CNPq and CAPES for their financial support. Figure 1: AFM measurements on the AISI 1020 stainless steel samples surface before (blank) and after exposure to crude oil for a period of 15 days. A and C: topographic image. B and D: cross section graph of the topography, showing the surface profile of the steel and peak-peak height. A- steel surface without exposure to petroleum, showing the irregularities resulting from pre-treatment sanding; B- cross section graph of the topography, showing the surface profile of the steel and high values for peak to peak height; C- corrosion is evidenced by pit formation on the steel surface (arrow); D: topographic profile, indicating corrosion presented in previous image (arrow) and reduced values for peak to peak height. Figure 2: AFM measurements on the AISI 316 stainless steel samples surface before (blank) and after exposure to crude oil for a period of 36 days. A, C, E and G: 3D topographic images; B, D, F and H: cross section graphics along of the line of the topography. References 1) Heloisa Pinto Dias, Thieres M. C. Pereira, Gabriela Vanini, Pedro Vitor Dixini, Vinícius G. Celante, Eustáquio V. R. Castro, Boniek G. Vaz, Felipe P. Fleming, , Alexandre O. Gomes, Gloria Maria de F. Viegas Aquije, Wanderson Romão, “Monitoring the degradation and the corrosion of naphthenic acids by electrospray ionization Fourier transform ion cyclotron resonance mass spectrometry and atomic force microscopy”. Fuel, 126 (2014) 85–95. 2) Maurizio Ferrante, “Seleção de Materiais”, 1ed., Editora da UFSCAR, São Carlos, SP, (1996). 3) L. A. de Faria, S. Silva Venâncio, M. T. de Oliveira. “Raman Microspectroscopy of Some Iron Oxidesand Oxyhydroxides.” J. Raman Spectrosc. 28 (1997):873-8.

Baixar