JOURNAL INTEGRATED CIRCUITS AND SYSTEMS, VOL 1, NO. 3, JULY 2006. 39 Self-Assembled Polystyrene Micro-Spheres Applied for Photonic Crystals and Templates Fabrication Daniel S. Raimundo1, Francisco J. R. Fernandez2 and Walter J. Salcedo3 Laboratório de Microeletrônica, Departamento de Engenharia Elétrica, Escola Politécnica, Universidade de São Paulo, SP, Brazil Av. Prof. Luciano Gualberto, Trav. 3, no 158, São Paulo, SP, Brazil, 05508-900 Tel: +55(11)3091-5310, Fax: +55(11)3091-5585, email: [email protected] Abstract— The present work reports the fabrication of polystyrene self-assembled micro-spheres structures on silicon and glass substrates by vertical deposition process using polystyrene micro-spheres monodispersion solution. The temperature of the process, surface conditions and solution concentrations were carried on the self-assembling process. Applications of self-assembled polystyrene micro-spheres structures for photonic crystals and templates fabrication, in silicon technology, were shown. Multilayer polystyrene structures showed that could be applied to the fabrication of photonic crystal structures and inverse opal structures. Index Terms— self-assembling, polystyrene, template, photonic crystals, metallic mask. INTRODUCTION Self-assembly method has been currently utilized by the scientific community in the nanofabrication of materials. The self-assembly method consists of a spontaneous process by which molecules and nanophase entities may materialize into organized aggregates or networks. Through various interactive mechanisms of self-assembly, such as electrostatic, chemistry, surface properties, and via other mediating agents, the technique proves indispensable to recent nanomaterials fabrication and device realizations. In recent years, the systems composed of self-assembled nanometric beads become important for different applications, as patterned arrays in lithographic techniques, microlenses and templates for inverse opal structures for sensors and optical applications [1-2]. In optical applications, special attention has been given to photonic crystals enginnering area [3-4]. The idea of the periodic photonic crystals was conceived by Yablonovitch [5]. One-dimensional (1-D) photonic crystal structure consists of alternating layers of materials with different refractive index. A two-dimensional (2-D) photonic crystal structure is periodic along two of its axes and homogeneous along the third. A three-dimensional (3D) photonic crystal is periodic along the three axes. The possibilities of controlling light emission, absorption and propagation in optoelectronic and photonic devices have generated intense research in the field of photonic crystals (PCs) engineering [6]. A simple and effective process to obtain organized structures is the self-assembling technique of colloidal spheres. The combination of the capillary forces, the convective transport of spheres towards the substrate surface, the horizontal force induced by the evaporation process and the self-assembling effect, lead to the formation of the organized array structures of spheres based on self-assembling concept [7]. A special characteristic of structures obtained by microspheres self-assembling is that the porous materials acquired have spherical voids, which were occupied originally by the colloids. The monodisperse micro or nanometer colloids (organic or inorganic) [8] usually adopt face-centered cubic (fcc) packing with approximately 26% voids in volume, into which the nanoparticles are easily infiltrated. The templates subsequently can be removed by sintering for organic or acid extracting for inorganic templates to acquire the organized porous network, in which the spherical voids are periodic and interconnected via small interstitial channels. A lot of nanoporous materials including inorganic, organic, metallic and ceramic have successfully been made using this method. Both organic and inorganic porous materials are very interesting for theoretical research and practical applications such as making optical filters, switches, and chemical sensors, and as carriers for catalysts and medicines [9]. Through various interactive mechanisms of selfassembling, such as electrostatic, chemistry, surface properties, and via other mediating agents, the technique proves indispensable to recent nanomaterials fabrication and devices realization. The present work reports the influence of the monodisperse concentration, temperature setup and initial surface condition of the substrate on the self-assembly of polystyrene microspheres formation, and also the possibility of the structures to be applied as photonic crystals and templates in porous silicon microelectronics technology. EXPERIMENTAL PROCEDURE In this experiment, polystyrene spheres were assembled onto glass and silicon substrates by vertical deposition to fabricate 2-D and 3-D self-assembled structures. The solutions that were used consisted of polystyrene micro-spheres monodispersions in aqueous solution. The diameter of polystyrene spheres was 660 nm. Before the self-assembling process, the glass substrates were cleaned in extran solution at 60oC and sonicated during 10 minutes. After it, the glass substrates were rinsed using deionized water during 10 minutes. Finally, these substrates were immersed into an ethanol solution and heated until completely dry to finish the cleanness. Silicon substrates, before the self-assembling process, were cleaned using conventional chemical microelectronics cleanness and were oxidized at 1000 oC to form a 300 nm SiO2 thickness, approximately. For the deposition 40 RAIMUNDO et al.: SELF-ASSEMBLED POLYSTYRENE MICRO-SPHERES AP. FOR PHOTONIC CRYSTALS AND T. FABRICATION of polystyrene spheres, the substrates were immersed into the solutions in vertical configuration and all the system was heated at temperatures of 35oC, 50oC and 65oC, using two different concentrations (1.72%wt and 0.86%wt) of polystyrene dispersion, to each temperature. In addition, to evaluate the surface conditions for the deposition, glass substrate surfaces were treated with HF (fluoridric acid) after the cleanness process and before the deposition. To the formation of metallic organized structures, a gold metallic thin film (12 nm) was deposited on the structure by the Sputtering technique. These metallized structures were sintered at 200 oC in air for 1 hour to promote good adherence of the metallic film (gold), at interstitial regions, on the substrates; and to sinter the polymer. Finally, the samples were immersed in sonicatingchloroform solution in order to remove the polystyrene spheres (the template) by chemical dissolution of the polymer. A 515 Philips Scanning Electron Microscope (SEM) was used for direct morphological characterization of lattice of the samples using the secondary electrons technique with a 30 KeV energy. A Varian Cary 500 UV-VIS-NIR Spectrophotometer was used for optical characterization to verify the band gap existance. RESULTS AND DISCUSSION The self-assembled polystyrene structures for all the samples showed hexagonal compact periodic array with lattice constant of c.a 660 nm (Figures 1 and 2). The hexagonal compact array showed thermodynamic preference because of the existence of the lowest minimum Gibbs free energy for these structures (3). As follows, it will be discussed the self-assembled polystyrene structures in function of the monodisperse solution concentration and the temperature level used for the solvent evaporation during the PCs formation. In addition, it is worth discussing the surface substrate condition. The self-assembled structures obtained on glass substrate by setting up temperature levels at 35 oC and 65 oC and using two different concentrations of polystyrene spheres aqueous solution c.a 1.72%(wt) and 0.86%(wt) are showed in figure 1. The mechanisms of the self-assembled structure with polystyrene spheres can be explained as follows: in initial state, a positive meniscus region is formed on the substrate due to wetting from the solution and hydrophilic surface condition. Water evaporation out of this thin meniscus, which leads to the flux and accumulation of polystyrene spheres and lateral capillary force, plays important roles in the colloidal crystals formation (7). The samples obtained at 35 oC (figures 1(a) and 1(b)) showed two-layer structure with highly local organized aggregation. The structures obtained at 65 oC showed four-sphere layers (a) (b) (c) (d) Fig. 1 SEM images of photonic crystals structures obtained on glass substrates at (a) 35 oC and 1.72%wt (b) 35oC and 0.86%wt (c) 65 oC and 1.72%wt, and (d) 65 oC and 0.86%wt. The images (a), (b) and (c) were 10,000 times magnified and the image (d) was 5,000 times magnified. (3-D structure) at two different polystyrene sphere concentrations (figures 1(c) and 1(d)). However, the structure obtained with lowest concentration solution of polystyrene spheres (0.86%wt), showed non-organized local aggregate sphere structure JOURNAL INTEGRATED CIRCUITS AND SYSTEMS, VOL 1, NO. 3, JULY 2006. 41 (a) Fig. 3 Transmittance spectra of two-dimensional (2-D) and threedimensional (3-D) photonic crystals structures. The curves present photonic band gaps at near infrared region. (b) (c) (d) Fig. 2 SEM images of photonic crystals structures obtained on silicon substrates at (a) 35 oC and 1.72%wt (b) 35oC and 0.86%wt (c) 65 oC and 1.72%wt, and (d) 65 oC and 0.86%wt. The images (a) and (b) were 10,000 times magnified and the images (c) and (d) were 5,000 times magnified. (figure 1(d)). The high evaporation speed of the solvent with low concentration solution, promote the rise of kinetic energy of polystyrene spheres, producing non-organized structure. It is worth mentioning that samples obtained at 50 o C and with both solution concentrations showed three- layer structures (figures not shown at this paper). Then, it was verified that the increasing of the temperature promote the increasing of the number of structure layers, perhaps because of the velocity of the evaporation rate. High evaporation rates and high flow velocities promote the aggregation of spheres, forming multilayers. Then the evaporation temperature during vertical deposition is an important parameter during crystal growth. An evaporation temperature near 50oC with 0.22wt% polystyrene monodispersion concentration showed the point of optimum balance between the particle transfer process an its assembly into the array in order to obtain a monolayer structure (Figure 5 (a)).The samples obtained on oxidized silicon substrate at temperature of 35 oC and 65 oC using two polystyrene spheres aqueous solution concentration c.a 1.72%(wt) and 0.86% (wt) are showed in Figure 2. The sphere aggregated structures are similar to those obtained on glass substrate, but at 65 oC temperature setup with 0.86%(wt) solution concentration, the spheres aggregation was dramatically non-organized at all regions of the substrate (figure 2(d)) that was completely different from the structure obtained on glass substrate. The glass surface was treated with KOH aqueous solution in order to generate the hydrophilic surface on glass substrate. The silicon oxide layer was obtained by thermal oxidation process, so the SiO2 surface has had slightly hydrophobic condition. This different surface condition obtained at 65 oC and 0.86%(wt) solution concentration, could have promoted the dramatic difference between the structures that were obtained on SiO2 and glass substrates. All the samples obtained on SiO2 and glass substrates showed crack defects between PCs domains. The formation of these cracks is associated with liquid evaporation during the growing process. Cracks are distributed on many regions of the films, and the pattern of the hexagonal packing is preserved between them. Finally, at low temperature (35oC), the evaporation rate and evaporation velocity are low, promoting the formation of structures with a reduced number of defects. 42 RAIMUNDO et al.: SELF-ASSEMBLED POLYSTYRENE MICRO-SPHERES AP. FOR PHOTONIC CRYSTALS AND T. FABRICATION Fig. 4 SEM image of an amorphous silicon inverse opal structure obtained by three-dimensional self-assembled polystyrene structure. The image was 20,000 times magnified and presents an 1µm-dimension bar. (a) (b) phenomena, and then a good defined absorption band can be observed (Figure 3). The appearance of band gaps shows that the obtained structures are photonic crystals. The photonic band gap obtained with polystyrene spheres was so narrow because of the low contrast of the refractive index between polystyrene spheres (n=1.54) and air (n=1.00). To increase the width of photonic band gaps is necessary to increase the contrast of refractive index of materials that compound the structure. The 3-D polystyrene spheres can be used as an excellent molding structure in order to obtain inverse opal structures. In this sense polycrystalline silicon film was deposited onto the polystyrene 3-D structure by PECVD technique after the film annealing at 400 oC in N2 ambient. After, the polystyrene spheres were dissolved by chloroform solution and finally, the obtained final film showed an inverse opal as can be seen in Figure 4. The monolayer polystyrene spheres array was used to obtain a gold metallic mask fabrication throughout the following procedure: The gold film (~12nm) was deposited onto the polystyre monolayer structure by Sputtering technique. After, the polystyrene spheres were removed by chloroform solution, remaining the gold metal at the spheres interstitial regions. The remaining metal showed a wellorganized pattern with regular distributed region withouth metal. (the previous site of polystyrene spheres) with separation distance between then within the resolution of polystyrene spheres size as can be seen in Figure 5 (b). Finally we can conclude that the regular and organized structures of polystyrene spheres not only can be used to photonic crystal structure fabrication, but also can be used to fabricate metallic masks using self-organized structures as template. Furthermore, the self-asembling technique is an easy manner to reduce the resolution of the masks in silicon technology, especially because of the easy implementation and low cost. At present this gold metallic mask is being used for photonic crystal fabrication on silicon substrate using porous silicon technology which results will be reported in the next paper. CONCLUSIONS Fig. 5 SEM images of (a) a monolayer structure of polystyrene microspheres obtained with a 0.22wt% monodispersion at 50 oC, and (b) a metallic mask obtained by the structure (a) after the total removal of spheres. (a) indicates a angular view (60 degrees) and (b) indicates a top view. Images (a) and (b) were 40,000 times magnified and present 1µmdimension bar. The transmittance spectra of samples with one and two layer structure are showed in figure 3. It can be observed that absorption band (band gap) shifts down as number of layers decreases. The absorption spectra were obtained by normal incidence of light beam relative to surface of structure. The monolayer absorption band structure is probably due to a single layer (660 nm) diffraction phenomena, i.e, the hexagonal array structure doesn’t contribute to diffraction phenomena. For the samples with two or more layers, the polystyrene spheres array is responsible for diffraction The self-assembly method used to the fabrication of two-dimensional (2-D) and three-dimensional (3-D) regular periodic structures showed a very good and cheap alternative to the formation of 2-D and 3-D photonic crystal structures. The temperature and polystyrene monodispersion concentration were showed as sensible parameters for selforganized structure formation. The number of selfassembled layer is correlated with temperature used at experimental processes. Multilayer structure (>2 layers) was formed at high temperature set-up (65 oC). At this temperature, the lowest dispersion concentration showed to be the worst condition to the formation of arranged films, especially when they are associated with a slightly hydrophobic condition of the SiO2 surface. The transmittance spectra at near infrared region showed the existence of more defined photonic band gap structure feature with the increasing of the number of self- organized layers. Multilayer polystyrene structures showed that can be applied to the fabrication of JOURNAL INTEGRATED CIRCUITS AND SYSTEMS, VOL 1, NO. 3, JULY 2006. photonic crystal structures and inverse opal structures. Monolayers polystyrene structures showed that could be applied as template in the fabrication of photonic crystal structures based on porous silicon technology. Furthermore, the self-assembling technique is an easy manner to reduce the resolution of the masks in silicon technology, specially because of the easy implementation and low cost. Then, it is possible to reduce the masks resolution to values by 660 nm. ACKNOWLEDGEMENTS The authors thank CNPq and FAPESP for financial support, and Laboratório de Microeletrônica and Laboratório de Sistemas Integráveis at Escola Politécnica, Laboratório de Cristais Iônicos, Filmes Finos e Datação at Instituto de Física and Laboratório de Espectroscopia Molecular at Instituto de Química, from Universidade de São Paulo, for technical support. 43 VI. REFERENCES [1] Z. Gu et al, Langmuir, 17, 6751 (2001). [2] G. G. Pereira, Current Applied Physics, 4, 255 (2004). [3] Y. H. Ye et al, Applied Physics Letters, 78, 52 (2001). [4] B. Gates and Y. Xia, Applied Physics Letters, 78, 3178 (2001). [5] E. Yablanovitch, Phys. Rev. Lett., 58, 2059 (1987). [6] J. D. Joannopoulos, R. D. Meade and J. N. Winn. Photonic Crystals, Princeton (1995) [7] S. Rakers, L. F. Chi and H. Fuchs, Langmuir, 13, 7121 (1997) [8] Y. Yin, Z. Li, Y. Xia, Langmuir, 19, 622 (2003) [9] V. Valtchev, J. Mater. Chem., 12, 1914 (2002)

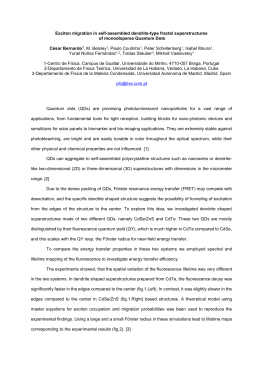

Baixar