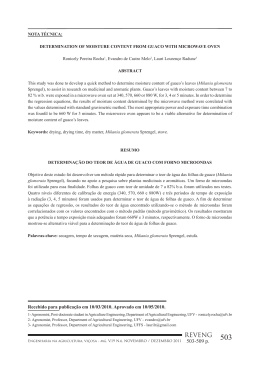

Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.11, n.2, p.117-121, 2009 ISSN 1517-8595 117 MATHEMATICAL MODELING Of THE DRYING KINETICS OF SUGARCANE SLICES Nahia Agote Goyalde1, Evandro de Castro Melo2, Ronicely Pereira Rocha3, André Luis Duarte Goneli4, Fabiana Lana Araújo5 ABSTRACT Sugarcane crop is most important economically, socially and environmentally. Brazil is the largest sugarcane producer in the world. With the objective of contributing towards precision agriculture, the air drying characteristics of sliced sugarcane (Saccharum spp) were investigated and made to fit into semi-theoretical models used to describe drying behavior. The drying tests were performed in an experimental fixed-bed dryer with upward air flow. The drying was carried out at two air temperatures: 50 and 60ºc with air relative humidity of 17.9 and 11.1, respectively. The time required for sugarcane drying, from an initial moisture content of 70% w.b. to the final moisture content of 6% w.b., was 7.5 and 3.5 h for drying temperatures of 50 and 60ºc, respectively. Experimental data were adjusted to 4 traditional mathematical models in order to represent the drying process of agricultural products. The Midilli model was the one that best described the sliced sugarcane drying process. Keywords: Saccharum spp, drying, mathematical modeling. MODELAGEM MATEMATICA DACINETICA DE SECAGEM DA CANA DE ACUCAR CULTIVADA RESUMO Notoriamente, a cultura da cana-de-açúcar tem grande importância econômica, social e ambiental, fazendo do Brasil o maior produtor mundial de cana. Com o propósito de contribuir com a agricultura de precisão, foi avaliada a obtenção das curvas de secagem da cana-de-açúcar cultivada (Saccharum spp) e ajustada a diferentes modelos matemáticos. A secagem foi realizada em um secador experimental a gás de leito fixo com fluxo de ar ascendente. Os testes foram realizados utilizando-se duas temperaturas de secagem, 50 e 60 ºC, com umidade relativa de 17,9 e 11,1, respectivamente. O tempo requerido para secar a amostra com teor de água de 70 para 6% b.u. foi de 7,5 e 3,5h para as temperaturas de secagem de 50 e 60ºC, respectivamente. Aos dados experimentais, foram ajustados 4 modelos matemáticos tradicionais para a representação do processo de secagem de produtos agrícolas. O modelo de Midilli foi o que melhor se ajustou aos dados de secagem da cana-de-açúcar picada. Palavras-chave: Saccharum spp, secagem, modelos matemáticos. Protocolo 1102 de 02/06/2009 1 Agricultural Engineer, Undergraduate student in Agricultural Engineering, UPNA, Pamplona-Spain, e-mail: [email protected]. 2 Agricultural Engineer, Dr. Professor in Agricultural Engineering, UFV, Viçosa – Brazil, Corresponding author. Tel.: +55 31 38991873, email address: [email protected] 3 Agricultural Engineer, Doctorate student in Agricultural Engineering, UFV, Viçosa – Brazil, email: [email protected] 4 Agricultural Engineer, Doctorate student in Agricultural Engineering, UFV, Viçosa - Brazil. 5 Animal Scientist, Máster student in Animal Science, UFV, Viçosa - Brazil. Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.11, n.2, p.117-121, 2009 118 Mathematical modeling of drying kinetics of sugarcane slices Goyalde et al. the objective of this work is to fit mathematical models to describe the drying process. INTRODUCTION Drying is one of the most widely used primary methods of food preservation. The objective of drying is the removal of water to the level at which microbial spoilage and deterioration reactions are greatly minimized (Akpinar & Bicer, 2004). In the development and improvement of equipment used for drying, the simulation and attainment of theoretical information about the behavior of each product during water removal is important. For the simulation, which is based on the principle of successive drying of thin layers of the product, a mathematical model that represents, satisfactorily, their water loss during the drying process is used (Berbet et al., 1995). In recent years, various investigators have undertaken studies covering mathematical modeling and kinetics of the vegetable drying process. For example, wheat (Sun & Woods, 1994), bean (Afonso Júnior & Corrêa, 1999), rough rice (Basunia & Abe, 2001), red pepper (Kaymak-ertekin, 2002; Akpinar et al., 2003), pear fruit (Lahsasni et al., 2004), parbolized wheat (Mohapatra & Rao, 2005), and tomato (Sacilik et al., 2006). Considering the fact that Brazil is the principal producer of sugarcane and its importance as an animal food and oil producer, MATERIAL AND METHODS The present work was carried out in the Agricultural Engineering Department, located at the Universidade Federal de Viçosa (UFV), Viçosa-MG, Brasil. The sugarcane used for the experiment was taken from Usina Jatiboca, in Rio Casca village, with traditional harvest techniques used for the sugarcane. After harvesting, the sugarcane was sliced with a mechanical machine (Nogueira EM-6400) to 6 mm approximately, and samples were taken for drying tests and initial moisture content. The sugarcane was sliced with moisture content of 70% w.b., measured by applying the gravimetric method at 105 ± 1 ºC for a period of 48 hours in triplicate. The drying tests were performed in an experimental fixed-bed dryer with an upward air flow. The drying was carried out under two air temperatures of 50 and 60ºC controlled by an automatic controller with ± 2 ºC of variation, as Jesus et al. (2001) describes (Figure 1). Figure 1 – Dryer view Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.11, n.2, p.117-121, 2009 Mathematical modelling of drying kinetics of sugarcane slices Air relative humidity was 17.9% and 11.1% at temperatures of 50 and 60ºC, respectively, measured with a thermo-hydro clock from Datamed company. The samples used in the experiment were placed in perforated plastic trays inside the dryer. The weight of the original sample was 140 g. A digital scale was used to weigh the samples, model Mark 420LC. The drying was completed when the samples weights were found constant. Then three samples were placed in the oven, model MA033, at 105 ± 1 °C for 48 hours to calculate the water content final. The moisture ratio (MR) was determined using the following expression: MR = M θ − Me Mi − M e 119 Goyalde et al where: MR: moisture ratio, dimensionless; Mθ: moisture content at time θ (kg water/kg dry mater); Mi: initial moisture content, (kg water/kg dry mater); Me: equilibrium moisture content, (kg water/kg dry mater). The equilibrium moisture content for sugarcane was taken from the work done by Rao (2006). The drying curves were adjusted from the experimental data using empiric and semi-empiric models reported in the literature, presented in Table 1 (Madamba et al, 1996; Doymaz, 2004; Mohapatra & Rao, 2005; Akpinar, 2006). (1) Table 1. Mathematical models used to describe the drying kinetics. Model designation Model Henderson and Pabis MR = a exp ( -k t ) (1) Logarithmic MR = a exp ( -k t ) + c (2) Midilli MR = a exp -k t Page MR = exp -k t ( ( n n )+bt (3) ) (4) where: t: Drying time (h); k: empirical coefficients in the drying model ( h-1 ); a, b, c, n: empirical constants in drying model. A regression analysis was performed using the drying mathematical models and the experimental data. The experimental data was interpreted by means of a non-linear regression analysis using the Quasi-Newton method executed with the Statistica 6.0® computer program. The drying models were selected based on the mean relative error (MRE), the standard error of estimate (SEE) and the determination coefficient (R2). The MRE and SEE were calculated for each model by the following expressions (Madamba et al., 1996, Mohapatra & Rao, 2005): 2 n ∑ M exp - M pre SEE = i =1 Df ( MRE = ) 100 n M exp - M pre ∑ n i =1 M exp (5) (6) where: n: Df: Mexp: Mpre: number of observations; degrees of freedom of the model; experimental observed values; estimated values by the model. Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.11, n.2, p.117-121, 2009 120 Mathematical modeling of drying kinetics of sugarcane slices Goyalde et al. Madamba et al. (1996), for 50 and 60ºC drying temperatures. The R2, SEE and MRE values of Midilli model are 0.999, between 0.007 and 0.010, and between 2.677 and 7.615, respectively. Therefore, the Midilli model may be assumed to represent the drying behavior of sugarcane slices. RESULTS AND DISCUSSION The calculated determination coefficient (R2), standard error of estimate (SEE) and mean relative error (MRE) for the models presented in Table 1 for 50 and 60ºC are presented in Table 2. All models achieve a R2 greater than 0.99, which is acceptable according to Table 2. Statistical analysis for the models using experimental data thin-layer drying of wheat. 50°C Model R 2 60°C 2 SEE MRE (%) R SEE MRE (%) Henderson and Pabis 0.999 0.010 11.156 0.996 0.026 21.979 Logarithmic 0.999 0.010 13.206 0.999 0.015 8.807 Midilli 0.999 0.007 7.615 0.999 0.010 2.677 Page 0.999 0.008 12.029 0.999 0.009 6.775 The estimated parameters of the Midilli model are represented in Table 3. The observed and estimated data are represented in Figure 1 as a function of the drying time for each temperature. Figure 2 shows good adjustment for the Midilli model to the experimental data. 1,0 50°C 60°C Estimated Midilli Moisture ratio 0,8 0,6 0,4 0,2 0,0 0 1 2 3 4 5 6 7 8 Time, h Figure 2. Experimental and predicted moisture ratios obtained using the Midilli model. Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.11, n.2, p.117-121, 2009 Mathematical modelling of drying kinetics of sugarcane slices The time required for sugarcane drying from an initial moisture content of 70% w.b. to the final moisture content of 6% w.b. was 7.5 and 3.5 hours, at temperatures of 50 and 60 oC. Figure 1 verifies that higher temperatures allow for faster evaporation rates. Goyalde et al 121 slices. The time required for the sugarcane drying from an initial moisture content of 70% w.b. to the final moisture content of 6% w.b. was 7.5 and 3.5 hours, at temperatures of 50 and 60ºC ACKNOWLEDGMENTS CONCLUSIONS The Midilli model may be assumed to represent the drying behavior of sugarcane BIBLIOGRAPHY REFERENCE Afonso Júnior, P. C.; Corrêa, P. C. Comparação de modelos matemáticos para descrição da cinética de secagem em camada fina de sementes de feijão. Revista Brasileira de Engenharia Agrícola e Ambiental, v.3, n.3, p.349-53, 1999. Akpinar, E. K.; Bicer, Y.; Yildiz, C. Thin layer drying of red pepper. Journal of Food Engineering, v.59, n.1, p.99-104, 2003. Akpinar, E. K.; Bicer, Y. Modelling of the drying of eggplants in thin-layers. International Journal of Food Science and Technology, v.39, N.1, p.1–9, 2004. Akipinar, E. K. Mathematical modeling of thin layer drying process under sun of some aromatic plants. Journal of Food Engineering, v.77, n.4, p.864-870, 2006. Basunia, M. A.; Abe, T. Moisture desorption isotherms of medium-grain rough rice. Journal of Stored Products Research, v.37, n.2, p.205-19, 2001. Berbert, P.A.; Queiroz, D.M.; Silva, J.S.; Pinheiro Filho, J.B. Simulation of coffe drying in a fixed bed with periodic airflow reversal. Journal of Agricultural Engineering Research, v.60, n.3, p.16773, 1995. Doymaz, I. Drying kinetics of white mulberry. Journal of Food Engineering, v.61, n.3; 341-346, 2004. Jesus, J.C.; Radunz, L.L.; Melo, E.C.; Souza, J.A.; Rocha, R.P.; Berbert, P.A. Sistem de Thanks to FAPEMIG, CNPq and CAPES for the financing support during the project. controle automático da temperatura do ar de secagem em secador de plantas medicinais. Revista Brasileira de Produtos Agroindustriais, v.3, n.1, p.4346, 2001. Kaymak-Ertekin, F. Drying and rehydrating kinetics of green and red peppers. Journal of Food Science, v.67, n.1, p.168-75, 2002. LahsasnI, S.; Kouhila, M.; Jahrouz, M.; jaouhari, J.T. Drying kinetcs of prickly pear fruit (Opuntia ficus indica). Journal of Food Engineering, v.61, n.2, p.173-9, 2004. Madamba, P. S.; Driscoll, R. H.; Buckle, K. A.. The thin-layer drying characteristics of garlic slices. Journal of Food Engineering, v.29, n.1, p.75–97, 1996. Mohapatra, D.; Rao, P. S. A thin layer drying model of parboiled wheat. Journal of Food Engineering, v.66, n.4; p.513-518, 2005. Rao, P. V. K. J. Moisture Sorption Isotherms of Sugarcane, Palmyra and Date-Palm Jaggery. IN: ASABE ANNUAL INTERNATIONAL MEETING, 2006, St. Joseph, Anais… St. Joseph: UMN, 2006. Sacilik, K.; Keskin, R.; Elicin, A. K. Mathematical modeling of solar tunnel drying of thin layer organic tomato. Journal of Food Engineering, v.73, p.231–238, 2006. Sun, D. W.; Woods, J. L. Low temperature moisture transfer characteristcs of wheat in thin layers. Transactions of ASAE, v.37, n.4, p.1919-26, 1994. Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.11, n.2, p.117-121, 2009 122 Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.11, n.2, p.122, 2009

Baixar