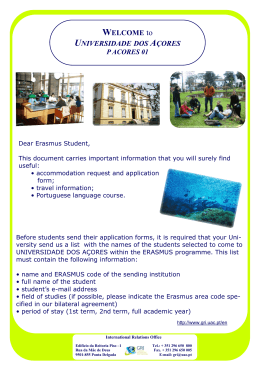

MT-4159-2007 The bridge to more efficient care PONTA SUPPLY BEAMS 02 | PONTA SUPPLY BE AMS MT-3987-2007 MT-3965-2007 MT-3978-2007 MT-4056-2007 more versatile Uniting improved care with individual flexibility Today’s increasingly complex critical care environments require delivering quality care as efficiently as possible. At the same time hospital budgets are becoming tighter. Therefore, organizing technology in a very flexible way and achieving that flexibility more cost-effectively is of major importance. Ongoing innovation Our products are built on a 100-year heritage of experience in healthcare, including more than 50 years of experience in medical gas- and supply systems. With a proven track record of innovations and thousands of beams sold, Dräger Medical offers a high performance standard. – 1958 Ceiling supply units – 1975 Supply systems for anesthesia machines – 1986 Beam systems – 1995 Vertical workplace concept “Gemina” – 1997 “Ponta E/S” patented cable routing enables low positioning of medical gases, electricity, IT – 2004 “MediaDocking” – One step connection of gases, electricity and IT between medical devices and supply units – 2005 Color-coded control functions for fast and intuitive positioning of supply units PONTA SUPPLY BE AMS | 09 TECHNICAL DATA S-Shuttle Linear travel Braking Maximum load4) Maximum load4) Rotation LengthSwiveling arm From central point (positioned as required) Pneumatic/Pneumatic/Friction With Agila supply head or column With Movita supply head or column Swiveling arm 400 mm ±550mm (total 1100mm) Linear travel/Arm/Column or Head 100 kg 100 kg 330° Lighting Systems Indirect light Illuminants Control Reading/Examination light Illuminants Control Night light lluminants Control According to DIN EN 12464-1 (Standard) In top of beam, removable cover 2 or 3 x 54 W fluorescent tubes Switched/Rotational or Touch dimming (Optional) In front profile, removable cover 2 x 24 W fluorescent tubes Switched/ Rotational or touch dimming (Optional) In top of beam, removable cover 1x7W Switched Data for planning software on request 100-127 V, 220-240 V, 50-60 Hz according to requirements As required 100-127 V, 220-240 V, 50-60 Hz Supply outlets Beam Agila head/column Movita head/column Gas, electricity, IT, etc. Max: 74 outlets (Ponta C 3500mm) Max: 51 outlets (Agila column 1500mm) Max: 102 outlets (Movita column 1500mm) As required See “Product Technical Specification_Ponta” See “Product Technical Specification_Agila” See “Product Technical Specification_Movita” MDD 93/42/EWG DIN EN 60601 – 1 DIN EN 60601-1-2 DIN EN ISO 11197 EN ISO 14071 18-046 During operation + 5 °C up to + 40 °C < 100% Class II b Standards According to Medical Device Directive Medical electrical devices Medical electrical devices Medical Supply Units Risk analysis – Medical products UMDNS code Ambient conditions Temperatur Relative humidity Installation instructions, English Catalogue, English 4) Workstation Components for Supply Units Maximum load that can be carried on the supply head or column As required 100-127 V, 220-240 V, 50-60 Hz 2 possible for beams > 2200 mm During storage – 20 °C up to + 60 °C < 100% 90 39 161 90 48 440 04 | PONTA SUPPLY BE AMS all-encompassing Connecting clinical professionals to a more effective care environment C-workstation –pole MT-466-2008 C-workstation –rack The C-workstations are designed for maximum utilization of space. The equipment- pole and carrier have a very slim design and medical devices can be positioned anywhere along the length of the beam. Gas, electricity and IT supplies are located in the beam. Designed for the way caregivers work Caring for increasingly higher acuity patients is very challenging for caregivers. This is why a workplace that is organized from top to bottom becomes so valuable. – Different shuttle types, supply heads and columns can be combined to provide high degree of workstation configurability – Vertical equipment positioning enables unobstructed patient access – The rail system allows a defined, secure and easy movement along the beam – All Ponta systems are equipped with brakes that can be operated with just one hand 05 | PONTA SUPPLY BE AMS A state-of-the-art system ... E-workstation –Movita column E-workstation –Movita head The E-workstations enable low positioning of medical gases, electricity and IT within the column or head. This supports efficient equipment exchange and saves precious time during transport or critical situations. Additional supplies can be located in the beam. A pneumatic brake prevents unintentional movement. Designed to work in harmony with its surroundings A variety of lighting systems provide individual illumination options. Cleaning is possible at any time, independent from patient presence, which helps speed up the admission and discharge process within the ICU. In addition, all systems are sealed to make cleaning easier. – Indirect, glare-free lighting creates a pleasant atmosphere for patients, caregivers and visitors – Direct lighting enables comfortable reading and provides a high quality light source for examinations – Night lighting allows caregivers to work without interrupting the patient’s sleep – Optional color schemes for the supply units make the patient room more comfortable PONTA SUPPLY BE AMS ... for caregivers, patients and visitors alike S-workstation –Agila column tube S-workstation –Agila column If preferred, the H-option routes gases, electricity and IT through external hoses. This option is available for the E- and the S-workstations. MT-468-2008 The S-workstations maximize positioning flexibility by incorporating a rotating arm. It enables the workstation to be positioned to the side or headof the bed. Both shuttle and arm include a pneumatic brake. As with the E-workstation supplies for medical gases, electricity and IT are positioned low and additional supplies can be located in the beam. | 06 07 | PONTA SUPPLY BE AMS MT-467-2008 more economical Creating a pathway to long-term value Cost-effective design A broad portfolio of harmonized accessories, beams, shuttles and equipment carriers can be combined to match a customer’s specific design and budget requirements. – A minimized number of assembly components enables fast and easy installation – Costs associated with repositioning of existing services or the creation of sub-constructions can be avoided due to the variable positioning of the ceiling fixations Proven investment protection – Durability through Dräger’s high quality standards – The use of common and compatible mountings for accessories allows easy adaptation to changing requirements – The Ponta beam system frees up ceiling space for future installations, such as patient-lifters and infotainment systems – Ponta is backed by trusted DrägerService® support, which helps reduce downtime and optimize equipment life and lifecycle operating costs 08 | PONTA SUPPLY BE AMS TECHNICAL DATA Ceiling fixation Heavy duty anchors and suspension tubes Torque at the ceiling Suspension tubes Lengths available Diameter Load capacity Supply beam Recommended clearance height (under side of beam to floor) Beam width Beam thickness Balkenhöhe Beam weight Beam color Supply installation plate color End-cap length C-Shuttles Load capacity Standard rail Load capacity rail Linear travel Braking Maximum load4) Rotation E-Laufkatze Linear travel Braking Maximum load4) 1500, 2000 mm 110 mm 250 kg each Can be shortened as required C-shuttle (supplies in beam) E-shuttle (supplies in column/head) S-shuttle (supplies in column/head) 2200, 2800, 3100, 3500 mm 588 mm 212 mm C/H type E/S type NCS-S-0500 N : white Anodized aluminum, NCS-S-0500 N, Dräger Munsel blue or according to Color Line concept3), others on request 121mm each 1800-2000 mm 2100 mm1) 2350 mm1) Custom lengths available on request 2) 3) 25,5 kg/m2) 28 kg/m2) Powder coated Powder coated Under each shuttle On front of shuttle 10 kg Complete length of beam/beams Mechanical Equipment pole Equipment carrier Equipment carrier Linear travel and carrier rotation 60 kg 130 kg 170° From central point (positioned as required) Pneumatic/Friction Agila head/Column Movita head/Column ±550 mm (total 1100 mm) Linear travel/Column or Head 120 kg 120 kg If supplies are also located in the beam then a clearance height is required that permits ergonomic use! With mixture of shuttles use highest value See brochure “Dräger Color Line” – Order number: 90 50 361 4) Maximum load that can be carried on the supply head or column 1) Max. 1100 Nm per suspension tube 150 kg 25 x 10 x 294 mm Direct light | 03 D-1266-2009 D-1265-2009 D-1264-2009 PONTA SUPPLY BE AMS Indirect light Night light A more practical approach to critical care Dräger Medical beam systems are known for – all-round patient access – ergonomic workplace design – easy positioning of medical devices – direct access to gas, electricity and IT – integrated lighting – aesthetic design and help enhance hygiene and safety The latest generation of the Ponta beam system combines three previously separate systems into one and can meet more effectively individual therapeutic and workflow requirements in the ICU, NICU and Recovery. – Combining various beam length and shuttle types help optimize the work-place and improve process efficiency – A totally closed design helps prevent dust accumulation and facilitates cleaning – Integrated lighting is specifically designed to fulfill individual patient and caregiver needs flexible movement MT-465-2008 all-round patient access small workstation footprint HEADQUARTERS www.draeger.com As of August 2015: Dräger Medical GmbH changes to Drägerwerk AG & Co. KGaA. REGION EUROPE CENTRAL AND EUROPE NORTH REGION MIDDLE EAST, AFRICA, CENTRAL AND SOUTH AMERICA Dräger Medical GmbH Moislinger Allee 53–55 23558 Lübeck, Germany Tel +49 451 882 0 Fax +49 451 882 2080 [email protected] Dräger Medical GmbH Branch Office Dubai Dubai Healthcare City P.O. Box 505108 Dubai, United Arab Emirates Tel + 971 436 24 762 Fax + 971 436 24 761 [email protected] REGION EUROPE SOUTH REGION ASIA / PACIFIC Dräger Médical S.A.S. Parc de Haute Technologie d’Antony 2 25, rue Georges Besse 92182 Antony Cedex, France Tel +33 1 46 11 56 00 Fax +33 1 40 96 97 20 [email protected] Draeger Medical South East Asia Pte Ltd 25 International Business Park #04-27/29 German Centre Singapore 609916, Singapore Tel +65 6572 4388 Fax +65 6572 4399 [email protected] CANADA Draeger Medical Canada Inc. 120 East Beaver Creek Road Suite 104 Richmond Hill Ontario L4B 4V1 Tel +1 905 763 3702 Toll-free +1 866 343 2273 Fax +1 905 763 1890 [email protected] Manufacturer: Dräger Medical GmbH 23542 Lübeck, Germany The quality management system at Dräger Medical GmbH is certified according to ISO 13485, ISO 9001 and Annex II.3 of Directive 93/42/EEC (Medical devices). 90 51 512 | 09.10-5 | Marketing Communications | LSL | LE | Printed in Germany | Chlorine-free – environmentally compatible | Subject to modifications | © 2010 Drägerwerk AG & Co. KGaA Drägerwerk AG & Co. KGaA Moislinger Allee 53–55 23558 Lübeck, Germany

Baixar