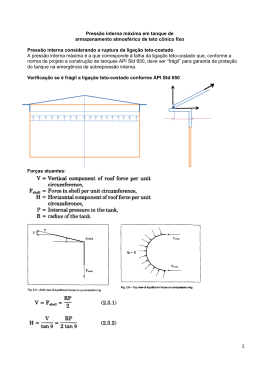

Comparision of the Native Microflora of Portuguese “BROA” and that of Similar Sourdough Breads J. Miguel Rocha and F. Xavier Malcata Escola Superior de Biotecnologia, Universidade Católica Portuguesa, Rua Dr. António Bernardino de Almeida, 4200 Porto, Portugal INTRODUCTION EXPERIMENTAL RESULTS AND CONCLUSIONS Ground cereals mixed with water produce a dough which, after some time and owing to microorganisms present therein, may eventually become a sourdough which is characterized by a typical acid taste and an increased volume due to formation of gas. Both characteristics result from fermentation by complex endogenous microflora, and this type of fermentation was probably one of the first microbial processes employed by Man for food preservations purposes. According to some authors, the microflora in sourdough is a set of compatible strains of yeasts and lactococci (or cocci), synergistic interaction of which is likely to be an important factor towards production of unique flavours and textures. One bread that is still produced following such an ancient manufacturing procedure, at the farm level, in the Minho Region is (widely) known as BROA. 8% 1% 2% 2% 3% 3% 1% 2% 2% 1% 1% 2% 1% 1% 1% 3% 1% 1% 1% 1% 5% 7% 1% 1% 38% 2% 8% 1% 2% 8% 2% 1% 2% 2% 2% 1% 2% 3% 1% 7% 1% 1% 1% 1% Manufacture of BROA plays important roles, from both economic and social standpoints, but a long way is yet to be tracked before such food specialty can be officially certified. To this goal, sequential steps of microbial quantification and identification have been taken, namely using samples from said maize bread manufactured in Cabeceiras de Basto. Almost 420 isolates were tested, via appropriate BioMérieux API™ kits; most of them had been already recorded in traditional sourdough breads from other countries, although their profiles were somewhat unique in our case. MATERIAL AND METHODS Flour of maize and rye, as well as sourdough samples (10 g) from Cabeceiras de Basto, were suspended in 90 ml of sterile 2% (w/v) sodium citrate, homogeneized in sterile beakers for 12 min and kept without agitation for an extra 8 min. Serial decimal dilutions were then made on 0.1% (w/v) sterile peptone water. The samples were plated in duplicate. Total viable counts were performed after inoculation and incubation on such media. Purified strains were first subject to several tests (Gram and spore staining, motility, catalase, oxidase, homo/heterofermentative and aerobic/anaerobic fermentation tests). Strains were further characterized via appropriate API galleries (see Figure 1). Table 1 - Experimental Conditions Microorganisms VRBDA Enterobacteriaceae YEDCA 2 vials/l X209 BCM 100 ml/l X073 2 vials/l X074 MRS Yeasts and Molds Bacillus cereus 1% 1% Aerococcus viridians Bacillus badius B. circulans B. macerans B. pumilus C. guilliermondii Chryseomonas luteola L. curvatus L. plantarum Leuconoctoc spp. Micrococcus kristinae Pichia ohmeri P. stutzeri Staphylococcus aureus S. schleiferi Streptococcus agalactiae Xanthomonas maltophilia Aeromonas hydrophila/caviae B. brevis B. laterosporus B. mycoides B. stearothermophilus C. pelliculosa Gardnerella vaginalis L. delbrueckii ssp. delbrueckii Lactococcus lactis ssp. cremoris L. mesenteroides ssp. cremoris Micrococcus spp. Pseudomonas cepacia Saccharomyces cerevisiae S. chromogenes S. sciuri S. constellatus Agrobacterium radiobacter B. cereus B. licheniformis B. polymyxa Candida colliculosa C. sphaerica Lactobacillus brevis L. lactis spp. lactis L. lactis lactis Listeria spp. Pediococcus spp. Pseudomonas spp. Sphingobacterium paucimobilis S. lentus S. xylosus S. equinus 1% 4% 7% According to these authors [1 12], the microflora in sourdough is a set of compatible strains of yeasts and LAB, synergistic interaction of which is likely to be an important factor towards production of unique flavours and textures. 4% 2% 1% 1% 4% 9% 1% 1% 1% 1% 1% 1% 1% 2% 1% 3% 41% 8% 5% 1% 3% Lactobacillus (Pediococcus and Leuconostoc) Staphylococcus aureus (Micrococcus) RCM Clostridium M17 agar Streptococcus (Lactococcus) Streptococcus (Enterococcus) Leuconostoc KF Streptococcus agar 2% 5% 1% 1% 4% 1% 2% 1% 1% 4% 1% 2% 1% 2% Aerococcus viridians Bacillus badius B. firmus B. megaterium B polymyxa Candida dattila Enterobacter agglomerans Lactobacillus brevis L. lactis ssp. Lactis Leuconoctoc spp. Micrococcus spp. Pseudomonas cepacia Staphylococcus capitis S. lentus S. xylosus S. equinus Aeromonas hydrophila/caviae B. cereus B. licheniformis B mycoides B. pumilus C. pelliculosa Enterococcus casseliflavus L. curvatus L. plantarum L. mesenteroides ssp. cremoris Pediococcus damnosus Saccharomyces cerevisiae S. cohnii S. sciuri Streptococcus adjacens Agrobacterium radiobacter B. circulans B. macerans B pantothenticus B. subtilis Chryseomonas luteola Gemella morbillorum L. delbrueckii ssp. Delbrueckii Lactococcus lactis ssp. lactis Listeria spp. P. pentosaceus Sphingobacterium paucimobilis S. hominis S. warneri S. constellatus Figure 3 - Species and corresponding frequency of appearance in MAIZE. 1% 2% 3% 1% 2% 3% 1% 1% 4% 2% 1% 4% 1% 1% T = 30 ºC; 48 h Spread plate under anaerobic conditions T = 30 ºC; 24 - 48 h T = 37 ºC; 48 h Spread plate under aerobic conditions T = 30 ºC; 48 h Spread plate under anaerobic conditions T = 30 ºC; 48 h Spread plate under anaerobic conditions T = 37 ºC; 24 h Spread plate under anaerobic conditions T = 30 ºC; 24 h Spread plate under aerobic conditions 2% 5% 1% 4% 1% 2% 1% 7% 1% 2% 32% 4% 13% 1% 3% 1% 1% 1% 1% YEASTS 1% 1% 1% T = 30 and 55 ºC; 24 h Spread plate under aerobic conditions T = 30 and 55 ºC; 24 h Spread plate under aerobic conditions T = 30 ºC; 24 h T = 37 ºC; 24 h Pour-plate method T = 30 ºC; 24 - 48 h Spread plate under aerobic conditions T = 37 ºC; 24 –48 h Spread plate under aerobic conditions 1% 1% 5% A major consideration concerning sourdough fermentation is its effect upon texture of the final bread, as a consequence of the carbohydrate metabolism of LAB, which is affected by flour composition or interactions with yeasts [7]. 1% 2% 5% 4% MSA MSE 2% Conditions Total viable counts (general and thermophilic viable counts) Spore counts (mesophilic and thermophilic spore counts) PCA 1% 2% Figure 2 - Species and corresponding frequency of appearance in SOURDOUGH. Total viable counts in samples of sourdough, maize and rye flour were obtained after inoculation on 10 different solid selective media poured onto Petri dishes. The identification of 419 isolates was via appropriate BioMérieux API™ galleries, after several preliminary biochemical and morphological tests; such identification has shown that the total counts on each medium do not correspond exactly to the expected group of microorganisms for that culture medium. In order to check for the existence of a wide diversity of microorganisms, a large number of culture media and incubation conditions were selected (see Table 1). Culture media and antibiotics Sourdoughs of similar breads originating in other countries contain complex microflora, where yeasts and lactic acid bacteria predominate, and which, owing to synergistic interactions, produce distinct acidic tastes and unique flavors [1 - 12]; these microorganisms and LAB are favored by the environmental conditions prevailing during storage, i.e. low temperatures and high relative humidities. 1% 8% 3% 1% 4% 1% 1% 1% ID 32C LAB and yeasts contributed by sourdough account for several volatile compounds produced during sourdough fermentation [5]: homofermentative LAB are responsible for development of a final bread with good grain and elastic crumb, whereas heterofermentative LAB improve taste and contribute to the leavening process. 4% 2% COCCUS Gram + Catalase + API STAPH COCCOBACILLUS Gram + Catalase - API 20 STREP Catalase + Catalase - API STAPH API 20 STREP BACILLUS GRAM + Catalase + B . c e re us B . s te aro the rm o philus C . m e m branae fac ie ns De baryo m yc e s m aram a E. durans Lac to bac illus ac ido philus L. lac tis s s p. lac tis Lac to c o c c us lac tis s s p. lac tis M . s pp. P e dio c o c c us pe nto s ac e us S ac c haro m yc e s c e re v is iae S . c o hnii S . s c iuri Xantho m o nas m alto philia Figure 4 - Species and corresponding frequency of appearance in RYE. It should be emphasized that sourdough leavening is mostly determined by CO2 produced as a result of the fermentative activity of yeasts present: although the gas developed in the sourdough contributes to open up texture, the lactic and acetic acids produced by LAB play a determinant role in taste [2, 8]. GRAM - REFERENCES Long Bacilli Obligate Anaerobes Obligate Aerobes Oxidase Catalase - Aero-Anaerobes API 20 NE API 50 CHB B ac illuc c irc ulans B . pum ilus C andida dattila C hrys e o m o nas lute o la E. c as s e liflav us E. fae c ium L. c urv atus L. plantarum M ic ro c o c c us k ris tinae P as te ure lla ae ro ge ne s P . ps e udo m alle i S taphylo c o c c us c hro m o ge ne s S . le ntus S . xylo s us Although this work has attempted to characterize the microecology prevailing in the main precursors of Broa (maize and rye flours, and sourdough), the characteristics of this matrix create a unique environment in which specialized, wild strains of microorganisms can grow. Aero - Anaerobies Longs rods sporuled A e ro m o nas hydro phila/c av iae B . lic he nifo rm is B . s ubtilis C . pe llic ulo s a Ente ro c o c c us av ium E. fae c alis L. c o pro philus L. parac as e i s s p. parac as e i Lis te ria s pp. M . v arians /ro s e us P s e udo m o nas c e pac ia S phingo bac te rium pauc im o bilis S . e pide rm idis S . warne ri API 50 CHL API 20 A Oxidase + Oxidase - API 20 E API 20 E [1] Barber, S., R. Báguena, M. A. Martínez-Anaya, and M. J. Torner. 1983. Microflora de masa madre panaria. I. Identificacíon y propiedades funcionales de microorganismos de masas madre industriales, elaboradas con harina de trigo. Rev. Agroq. Tecnol. Aliment. 23:552-562. [2] Boraam, F., M. Faid, and J. P. Larpent. 1993. Lactic acid bacteria and yeast associated with traditional Moroccan sour-dough bread fermentation. Sci. Alim. 13:501-509. [3] Collar, C., M. A. Martínez-Anaya, and C. B. Barber. 1994. Interactive effects between microbial breadmaking starters and wheat flours on sour dough and bread quality. Rev. Esp. Cienc. Tecnol. Aliment. 34:191-201. [4] Collar, E., C. B. Barber, and M. A. Martínez-Anaya. 1994. Microbial sour doughs influence acidification properties and breadmaking potential of wheat dough. J. Food Sci. 59:1994. [5] Dimiani, P., M. Gobbetti, L. Cossignani, A. Corsetti, M. S. Simonetti, and J. Rossi. 1996 The sourdough microflora: characterization of hetero- and homofermentative lactic acid bacteria, yeasts and their interactions on the basis of the volatile compounds produced. Lebensm.-Wiss. u. Technol. 29:63-70. [6] Faid, M., F. Boraam, A. Achbab, and J. P. Larpent. 1993. Yeast-lactic acid bacteria interactions in Moroccan sour-dough bread fermentation. Lebensm.-Wiss. u. Technol. 26:443-446. [7] Gobbetti, M., A. Corsetti, and J. Rossi. 1994. The sourdough microflora: Interactions between lactic acid bacteria and yeasts: metabolism of carbohydrates. Appl. Microbiol. Biotechnol. 41:456-460. [8] Gobbetti, M., A. Corsetti, and J. Rossi. 1995. Interaction between lactic acid bacteria and yeasts in sour-dough using a rheofermenter. World J. Microb. Biotech. 11:625-630. [9] Hansen, B., and A. Hansen. 1994. Volatile compounds in wheat sourdoughs produced by lactic bacteria and sourdough yeats. Z. Lebensm. Unters. Forsch. 198:202-209. [10] Lues, J. F. R., B. C. Viljoen, M. Miller, and B. A. Prior. 1993. Interaction of non-culture microbial flora on dough fermentation. Food Microbiol. 10:205-213. [11] Martínez-Anaya, M. A., M. L. Llin, M. P. Macías, and C. Collar. 1994. Regulation of acetic acid production by homo- and heterofermentative lactobacilli in whole-wheat sour-doughs. Z. Lebensm. Unters. Forsch. 199:186-190. [12] Mascarós, A. F., C. S. Martínez, and C. Collar. 1994. Metabolism of yeasts and lactic bacteria during dough fermentation relating functional characteristics of fermented doughs. Rev. Esp. Cienc. Tecnol. Aliment. 34:623-642. ACKNOWLEDGMENTS API 20 NE Figure 1 - Procedure used for identification of the isolates strains. The authors are grateful to several members of the Regional Directorate of Agriculture of Entre Douro e Minho (DRAEDM) and several local farmers for cooperation within the experimental program described. Financial support for author J. M. R. was provided by a Ph.D. fellowship within the program for the Creation of National Infrastructures in Applied Science and Investigation (CIÊNCIA), administered by the National Board for Scientific and Technological Investigation (JNICT, Portugal). Partial financial support was received from PAMAF – IED (Ministry of Agriculture, Portugal) through a research grant entitled “Pão de milho: caracterização do processo tradicional de produção e melhoramento tecnológico”.

Download