Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.12, n.1, p.45-54, 2010 ISSN 1517-8595 45 INFLUENCE OF AIR PARAMETERS ON SPRAY DRYING ENERGY CONSUMPTION Tatumi Kajiyama 1, Kil Jin Park 2 ABSTRACT The objective of this present research was to simulate and evaluate the performance of spray dryers in function of air characteristics using Matlab software. Simulations were conducted to identify the effect of the influence of inlet air temperature (from 100ºC to 140ºC) and of relative humidity of ambient air (from 20% to 80%) on energy consumption and thermal efficiency. It was found that energy consumption increased as drying air temperature and as relative humidity of ambient air increased. The thermal efficiency of the process diminished as drying air temperature and as relative humidity of ambient air increased. Keywords: thermal efficiency, temperature, relative humidity, matlab INFLUÊNCIA DOS PARÂMETROS DO AR NO CONSUMO ENERGÉTICO DO SECADOR ATOMIZADOR RESUMO Este trabalho foi realizado com o objetivo de simular e avaliar o desempenho do secador atomizador em função das características do ar utilizando o software Matlab. Simulações foram conduzidas para identificar as influências dos efeitos da temperatura do ar na entrada (de 100ºC a 140ºC) e da umidade relativa do ar ambiente (de 20% a 80%) no consumo energético e na eficiência térmica. Verificou-se que o consumo energético cresce com o aumento da temperatura do ar de secagem e da umidade relativa do ar ambiente. A eficiência térmica diminui com o aumento da temperatura do ar de secagem e da umidade relativa do ar ambiente. Palavras-chave: eficiência térmica, temperatura, umidade relativa, matlab Protocolo 103.012-10 de 28/04/2010 1 PhD - Technology Department of State University of Feira de Santana, Feira de Santana, BA, Brazil, E-mail: [email protected]. 2 Professor - School of Agricultural Engineering, University of Campinas, P.O. Box 6011. CEP: 13084-971. Campinas - SP, Brazil. E-mail: [email protected]. Address to correspondence should be sent. 46 Influence of air parameters on spray drying energy consumption INTRODUCTION Drying is one of the oldest and most common operations employed in industrial processes to preserve food. Drying is a process in which water activity in food is reduced by removing water in order to minimize deterioration caused by enzymatic and microbiological reactions and, therefore, prevent physical and chemical modification of products. Spray drying is a commonly used method of drying a liquid feed through hot gas in the production of powders. This technique is widely used in food and pharmaceutical manufacturing and presents not only a low operating cost, but also a short contact time. The development of new products has used an encapsulating agent in microencapsulation by spray drying. This wide application of spray drying in research of new products increases the need for engineers to better understand energy calculation with mass and heat balance concerning the spray drying process. With the scarcity of energy and its rising cost, it is important to evaluate energy consumption on the drying process. The cost of heating the drying air is the most important economic factor for the drying process. Therefore, the influence of air characteristics on energy balance is important when attempting to understand the drying process. Spray drying is the process that transforms fluids to a solid state in order to obtain powder products. The aim is to dry biological material as quickly as possible. Although the inlet air temperature is high, the thermal damages are few, due to very fast drying (short drying time). In the development of new products, an encapsulating agent, with good emulsifying capacity and low viscosity in aqueous solution, has been used in microencapsulation by spray drying. The encapsulation process, initiated with essential oil to prevent oxidation, volatile substance loss, and control liberation of flavor, extended to the incorporation of natural additives and ingredients to alter texture, improve nutritional quality, prolong shelf life, and control properties of processed foods (RÉ, 1998 and 2000). Spray drying is one of the most employed drying methods in the encapsulation process due to the wide disposal of equipment, low process cost, possibilities of using various types of encapsulation agents, good retention of volatile compounds, and good stability of the product (Reineccius, 1989; Desai & Park, 2005). The process of spray Kajiyama & Park drying is realized by dispersion of suspension drop into the drying chamber, where it contacts the hot air, in the form of a spray. The drying of 1 m3 of liquid generates 2x1012 uniform particles measuring 100µ m in diameter, equivalent to a surface area of 60.000m2 (Masters, 1972). The increase of surface area is a function of necessity of the drying rate increase subjected to drying air conditions. Duffie & Marshall, 1953, presented the variation of feed concentration, physicochemical feed properties, feed temperature, air temperature, and method, as well as atomization conditions as variables that affect the properties of powder. The important advantages of spray drying are: efficient control of product properties and qualities; drying thermal sensitive food and pharmaceutical products by short exposition time of drying; great quantities to process in continuous operation; relatively simple equipment; relatively uniform dimension of particles; and, low process costs (Filková & Mujumdar, 1995). The object being dried is always related to the prediction of the drying process time. The drying process time is fundamental in order to design and optimize the industrial drying plant. The drying rate must be related to a specific product with a determined process and drying equipment. The first rate of drying is characterized by constant rate period, in which water evaporates as a free liquid without bounding energy. In this period, the heat and mass transfer is equivalent. The second rate of drying is characterized by a falling rate period. The quantities of water present in the surface of the drying product are less than the quantities to evaporate. In this second period, heat transfer is not compensated by mass transfer, and the migration of water from inside the material to the surface limits the drying rate (Park et al., 2007). With spray drying, these two drying rate periods occur and the inflection point of these periods is referred to as a critical point, which relates to critical moisture content. SINGH & Heldmann, 1998, and Pereda et al., 2005, cited that the constant rate period is predominant for spray drying where the mass transfer occurs at drop surface. Once the critical moisture content is reached, the particle structure causes a reduction in the drying rate and, therefore, the interior diffusion of the drying material limits the drying process. Nowadays, with the scarcity and rising cost of energy, it is important to evaluate the energy consumption of the drying process. Masters, 1981, present some Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.12, n.1, p.45-54, 2010 Influence of air parameters on spray drying energy consumption disadvantages of spray drying. The outlet air has residual heat and to reach saturation condition to have maximum use of energy is difficult. The possible methods of saving energy are increasing the inlet air temperature and diminishing the outlet air temperature (Kessler, 1981). Brennan, 1992, presents some changes that would reduce energy consumption: (1) isolation of equipment; (2) recirculation of exhaust air; (3) heat recovery of exhaust air; (4) use of direct heater; (5) drying in two stages; (6) concentration of feed; (7) automation of the outlet air temperature. More details regarding energy consumption reduction can be found in Zargorzycki, 1983, Masters, 1972, Grikitz, 1986, Heldman & Hartel, 1977, and Driscoll, 1955. The cost of heating the drying air is the most important economic factor in the drying process. In addition, the improvements of computational methods are some of the most important contributions of technological progress that help in understanding the drying process. Advances in computer science and the facilities provided by the personal computer enable experimental data to be adjusted to mathematical models and simulations to be tested using specific software. Park et al., 2007, obtained the numerical solution of the Fick’s Law and Kajiyama & Park, 2008, studied the influence of feed parameters on spray drying energy consumption using Matlab, 2001. The objective of this work was to evaluate the influence of air properties on spray drying Kajiyama & Park 47 energy consumption and thermal efficiency using Matlab, 2001. MATERIAL AND METHODS Material Properties of dairy products according to Singh & Heldmann, 1998: • • • Feed flow rate, F=1kg/s; Critical moisture content, wet basis, Xc=0,45kgwater/kgproduct; Final moisture content to calculate drying time, Xf =0,05kgwater/kgproduct. The concurrent flow dryer configuration was used, according to Brennan et al., 1998. The ambient air considered for simulation was measured at a temperature of 30º C, 60% relative humidity, and 16 gwater/kgdryair of absolute humidity at Feira de Santana, BA, Brazil. The ambient air was heated to the desired simulation temperature before entering the dryer. After drying, the outlet air relative humidity was fixed at 70%. The characteristics of the heated air are presented in Table 1. The characteristics of ambient air with different relative humidity used in simulation are presented in Table 2. (Singh & Heldmann, 1998, Himmelblau, 1998 and Smith et al., 2000). Table 1- Characteristics of heated air according to temperature Ta (ºC) Twb (ºC) λwb (kJ/kg) Yf (gwater/kgdry air) 100 110 120 130 140 37 39 40 41 42 2414.1 2409.3 2406.9 2404.5 2402.1 42.0 45.5 49.0 52.5 56.0 Table 2 - Characteristics of ambient air at various levels of relative humidity RH (%) 20 30 40 50 60 70 Twb (ºC) 36 37 38 39 40 41 λwb (kJ/kg) 2416.4 2414.1 2411.7 2409.3 2406.9 2404.5 Y0 (gwater/kgdry air) 6 8 10 13 16 19 Yf (gwater/kgdry air) 38 40 42 44 47 50 Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.12, n.1, p.45-54, 2010 48 Influence of air parameters on spray drying energy consumption 80 42 2402.1 23 Where: Ta is heated air temperature; Twb is wet bulb temperature; λwb is latent heat at Twb; RH is the relative humidity of ambient air; Y0 is the absolute humidity of inlet drying air; and Yf is absolute humidity of outlet drying air. Mathematical considerations The humid heat of moist air is given by: C s = 1.005 + 1.88Y0 X − Xf W = F 0 1− Xf (2) W = M (Yf − Y0 ) (3) The energy needed to raise temperature is calculated by Equation 4: PG aq = M(H aq − H atm ) 53 TE = (energy required to evaporate moisture at T temperature/energy supplied to dryer) This leads to the following equation used to calculate TE (Strumillo & Kudra, 1986 and Kaminski et al., 1989): TE = (1) Where, Cs is humid specific heat of moist air. According to mass balance (Barbosa-Cánovas & Veja-Mercado, 2000): air (4) The energy consumption is simulated using Matlab, 2001 using Equations (1), (2), (3), and (4). The energy efficiency (or thermal efficiency: TE) of the dryer is defined as: Kajiyama & Park W∆H MC pa (Tain − Taatm ) (5) The energy needed to raise air temperature is calculated using Equation 6: PG aq = M(H aq − H atm ) (6) So, the thermal efficiency was simulated with Equation 7 using Matlab: TE = Wλ wb PG ev = M(H aq − H atm ) PG aq (7) The algorithms used in this work with software Matlab are presented in Figure 1. The calculations of energy consumption and thermal efficiency in function of air temperature are indicated. The calculations of energy consumption and thermal efficiency in function of relative humidity are indicated in parentheses. Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.12, n.1, p.45-54, 2010 Influence of air parameters on spray drying energy consumption Kajiyama & Park 49 START Data values: air mass flow (Idem), ambient air temperature (Idem) and absolute humidity (or drying air temperature), initial Calculate humid specific heat of moist air, equation (1). Calculate Evaporated water flow Yes Energy consumption thermal efficiency for temperature (or relative humidity) range? no and END No Data dependent of temperature: Drying air temperature, Wet bulb temperature (Idem), Latent heat (Idem), Absolute humidity of outlet drying air (Idem), (Absolute humidity of inlet drying air) Calculate humid specific heat of moist air, equation (1). Calculate air mass flow (Idem), equation (3). Calculate energy consumption (Idem), equation (4). Calculate thermal (Idem), equation (7). efficiency Figure 1 - Algorithms used to calculate energy consumption and thermal efficiency RESULTS AND DISCUSSION Influence of drying air temperature According to Equations (2) and (3), air flow decreases as drying air temperature increases. This diminishing trend is shown in Figure 2 in function of drying air temperature. The necessity of air flow is less when a high temperature is employed, which increases the drying potential, i.e. the absolute humidity of inlet drying air diminishes. To visualize the effect of temperature on relative humidity see Figure 3, which shows the relative humidity (RH) in function of drying air temperature at 16 gwater/kgdry air of absolute humidity. Figure 4 demonstrates the simulation result of the amount of energy consumption (PGaq) used to heat the drying air to desired temperature (Ta). Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.12, n.1, p.45-54, 2010 50 Influence of air parameters on spray drying energy consumption Kajiyama & Park Figure 2 - Air flow (M) in function of drying air temperature (Ta) Figure 3 - Relative humidity (RH) in function of drying air temperature (Ta) Figure 4 - Energy consumption (PGaq) in function of drying air temperature (Ta) Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.12, n.1, p.45-54, 2010 Influence of air parameters on spray drying energy consumption As expected, more energy is needed to obtain high temperatures of drying air (Equation 4). The function is non-linear because of the variation of the air’s heat capacity (Equation (1)) and because of air flow variation (M). The M diminishes as temperature increases to evaporate the water (W), but this Kajiyama & Park 51 decreasing is less than heating energy (air enthalpy). Figure 5 shows the thermal efficiency (TE) in function of drying air temperature (Ta). The thermal efficiency diminishes as drying air temperature increases, resulting in an increase of energy consumption in function of increasing drying air temperature, as shown in Figure 4 . Figure 5 - Thermal efficiency (TE) in function of drying air temperature (Ta) Influence of relative humidity Figure 6 shows the simulation result of energy consumption to heating air (PGaq) in function of relative humidity of ambient air (RH). Energy consumption increases as ambient air relative humidity increases. This fact results in increasing air mass flow (M) with increasing relative humidity to evaporate the same water (W). The energy needed to evaporate water in food diminishes slightly as relative humidity increases, as shown in Figure 6. The increasing wet bulb temperature of heated air diminishes latent heat as shown in Figure 7. Figure 6 - Heating (PGaq) and evaporation energy (PGev) in function of relative humidity (RH) Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.12, n.1, p.45-54, 2010 52 Influence of air parameters on spray drying energy consumption Kajiyama & Park Figure 7 - Latent heat (λwb) in function of relative humidity (RH) The thermal efficiency (TE) diminishes as relative humidity (RH) increases, as seen in Figure 8. This result is due to the increase in air heating energy and the decrease of energy used for evaporation, which can be seen in Figure 6. Figure 8 - Thermal efficiency (TE) in function of relative humidity (RH) CONCLUSIONS When the drying air temperature rises, the relative humidity diminishes, leading to an increase of the water absorption capacity. This increase of absorption capacity diminishes air mass flow to the same evaporation rate in drying. The magnitude of decreasing drying air flow is less than the magnitude of air heating energy that caused an increase in energy consumption as drying air temperature increased. This heating energy behavior exhibits decreasing thermal efficiency as drying air temperature increases. The water absorption capacity decreases as the air relative humidity increases, thereby, needing a major quantity of air mass flow for the evaporation rate in drying. Therefore, the energy consumption to heat the air increased as relative humidity increased. The evaporation energy decreased as relative humidity increased. These energy behaviors exhibit decreasing thermal efficiency as air relative humidity increases. AKNOWLEDGEMENTS We are grateful to the State University of Campinas (UNICAMP), the State University of Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.12, n.1, p.45-54, 2010 Influence of air parameters on spray drying energy consumption Feira de Santana, and the National Council for Scientific and Technological Development (CNPq). BIBLIOGRAPHICAL REFERENCES Barbosa-Cánovas, G. V.; Veja-Mercado, H. 2000. Desidratación de alimentos, Acribia; Zaragoza. (in Spanish). Brennan, J. G. 1992. Development in drying. In: Food Technology Internacional Europe, Sterling Publications Internacional, London, 77 – 80. Brennan, J. G.; Butters, J. G.; Cowell, N. D.; Lilley, A. E. V. 1998. Las operaciones de la ingeniería de los alimentos, Acribia; Zaragoza. (in Spanish) Desai, K. G. H.; Park, H. J.. Recent Developments in Microencapsulation of Food Ingredients. Drying Technology, 23, 1361-1394, 2005. Duffie, J. A.; Marshall Jr., W. R. 1953. Factors influencing the properties of spray dried materials. Chemical Engineering Progress, 49, 417-423. Filková, I.; Mujumdar, A. S. 1995. Industrial spray drying systems. In: Handbook of Industrial Drying, Marcel Dekker: New York. Driscoll, R. H. 1995. Energy efficiency in dryers and ovens. Food Australia, 310 – 314. Grikitis, K. 1986. Dryer spearheads dairy initiative. Food process, 27 -28. Heldman, D. R.; Hartel, R.W. 1997. Principles of food processing, Chapman and Hall; New York. Himmelblau, D.M. Engenharia química: princípios e cálculos, Livros Técnicos e Científicos; Rio de Janeiro. 1998 (in Portuguese). Kaminski, W.; Zbicinski, I.; Grabowski, S.; Strumillo, C. 1989. Multiobjective optimization of drying process. Drying Technology, 7, 1–16. Kajiyama, K.; Park, K. J. 2008. Influence of feed parameters on spray drying energy consumption. Journal of Food Process Engineering, (in press). Kajiyama & Park 53 Kessler, H. G. 1981. Food engineering and dairy technology, Verlag A. Kessler, Freising; Germany. Masters, K. 1972. Spray drying, Leonard Hill; London. Masters, K. 1981. Spray drying handbook, Longman Group Limited; London. Matlab. 2001. MATLAB - The Language of Technical Computing software, Version 6.1.0 Release 12.1; The MathWorks Inc. Park, K. J.; Ardito, T. H.; Ito, A. P.; Park, K. J. B.; Oliveira, R. A. De; Chorato, M. 2007. Effective diffusivity determination considering shrinkage by means of explicit finite difference method. Drying Technology. 25, 1313-1319. Park, K. J.; Antonio, G. C.; Oliveira, R. A. De; Park, K. J. B. 2007. Conceitos de processo e equipamentos de secagem. 121p. (in Portuguese) <http://www.feagri.unicamp. br/ctea/manuais/concproceqsec_07.pdf>. Access in: Oct, 9th. 2007. Pereda, J. A.O.; Rodríguez, M. I. C.; Alvarez, L. F.; Sanz, M. L. G.; Minguillón, G. D. G. F.; Perales, L. H.; Cortecero, M. D. S. 2005, Tecnologia de alimentos: componentes dos alimentos e processos, Artmed: Porto Alegre. (in Portuguese) Ré, M. I. 1998. Microencapsulation by spray drying. Drying Technology, 16, 1195-1236. Ré, M. I. 2000. Cápsulas inteligentes. Ciência Hoje, 27, 24-29. (in Portuguese) Reineccius, G. A. 1989. Flavor encapsulation. Food Reviews International, Chicago, 5, 147-173. Singh, R. P.; Heldmann, D. R. 1998, Introducción a la ingeniería de los alimentos, Acribia; Zaragoza. (in Spanish) Smith, J. M.; Van Ness, H. C.; Abbott, M. M. 2000. Introdução a termodinâmica da engenharia química, Livros Técnicos e Científicos; Rio de Janeiro. (in Portuguese) Strumillo, C.; Kudra, T. 1986. Drying: Principles, application and design, Gordon and Breach Science Publishers, London. Zagorzycki, P. I. 1983. Automatic humidity control of dryers. Chem. Engng. Prog., 66 – 70. Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.12, n.1, p.45-54, 2010 54 Influence of air parameters on spray drying energy consumption Kajiyama & Park NOMENCLATURE Cpa Cs F Hatm Haq ∆H M PGaq PGev RH Ta Tain Taatm Twb TE W Xf Heat capacity at constant pressure humid specific heat of moist air Feed flow rate Ambient air enthalpy Hot air enthalpy Heat of vaporization Air mass flow Thermal energy per time Energy for evaporation per time Relative humidity Heated air temperature Inlet air temperature Ambient air temperature Wet-bulb temperature of drying air thermal efficiency Evaporated water flow Moisture content at transition drying rate point, wet basis Final moisture content, wet basis kgwater/kgproduct X0 Initial moisture content, wet basis kgwater/kgproduct Yf Y0 wb Absolute humidity of outlet drying air Absolute humidity of inlet drying air Latent heat at Twb Xc kJ/kg ºC kJ/kgdry air ºC kg/s kJ/ kgdry air kJ/ kgdry air kJ/kg kg/s kJ/s kJ/s % ºC ºC ºC ºC kg/s kgwater/kgproduct gwater/kgdry air gwater/kgdry air kJ/kgwater Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.12, n.1, p.45-54, 2010

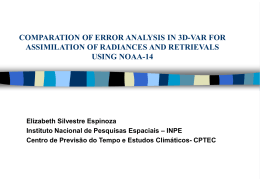

Download