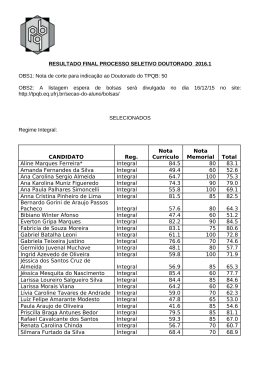

School of Chemistry PROFESSIONAL MASTER IN BIOFUELS AND PETROCHEMICAL ENGINEERING Executive Coordinator: Prof. Dr Maria Letícia Murta Valle Professional Master School of Chemistry, Federal University of Rio de Janeiro Brazil Postgraduate Program in Technology of Chemical and Biochemical Processes - TPQB 1st Class in March 2009 Professional Master in Biofuels and Petrochemical Engineering Why a Masters Degree in Biofuels, Petrochemicals and Fertilizers? Brazilian Reality: 1. Increase in consumption of anhydrous and hydrated ethanol: FLEX car and use of 20 to 25% v/v ethanol in gasoline 2. Increase in consumption of biodiesel: biodiesel content in diesel is 5% v/v 3. Brazil imports methanol to produce methyl biodiesel: use of ethanol is an alternative 4. New Investments in petrochemical plants, including in green petrochemicals, and nitrogen fertilizers Biofuels: Ethanol Around 18% of the fuels consumed in Brazil are already renewable. Brazil produces ethanol only from sugarcane. Brazilian cars run on two types of ethanol: 1. hydrated ethanol consumed in engines developed to this end or in flex fuel engines 2. anhydrous ethanol, which is mixed to gasoline without damages for the engine, in proportions between 20% to 25%. Ethanol Production: Hydrated and Anhydrous 2000 a 2012 Biofuels: Biodiesel Tens of vegetable species in Brazil can be used in the production of biodiesel (B100), namely soybean, palm, sunflower, babassu, peanut, castorbean and jatropha. However, soybean and tallow are the main raw materials used for the production of biodiesel Raw Materials Used in Biodiesel Production 2005 - 2012 Raw Materials Used in Biodiesel Production (B100) (m3) / 1000000 Raw Materials Used in Biodiesel Production (B100) (m3) / 1000000 Raw Materials Used in Biodiesel Production (B100) (m3) / 1000000 Biodiesel Production Evolution (B100) 2005 - 2012 Glycerin Resulting from Biodiesel Production – 2005 - 2012 Methanol Consumption 2005 - 2012 Fertilizers Increase in fertilizer consumption from 2012 to 2013: 3.6% 1. Nitrogen fertilizer: +7.1% 2. Potassic fertilizer: +2.8% Imports for 2013, related to 2012, will be: 1. 2. 3. 4. Intermediate: + 23.0%. Nitrogenous: +24.3% Phosphates : +40.4% Potassic : +13.7%. Construction of 5 Gas-Chemical Complex by Petrobras to Increase the supply of urea, methanol and its derivatives, reducing the need to import these products Petrochemical Petrobras is constructing the Rio de Janeiro Petrochemical Complex (Comperj) with a initial capacity of processing 165 thousand barrel per day. Brasken is investing highly in the search for alternative technologies that use renewable raw materials Diagnosis Social Demand ►There is a lack of specialists in these areas: 1. Biofuels 2. Petrochemical 3. Fertilizers Purpose of the PM and Egress Profile ►Enhance the experience of graduates ►Strengthen the technological training ►Form professionals who will contribute to the technological development of the biofuels sectors, petrochemicals and fertilizers The proposal of the TPQB Program: 4 Concentration Areas 1. Production processes of petrochemicals and fertilizers 2. Design of petrochemical plants and fertilizer 3. Process for biofuel production 4. Biofuels production plants design Research Areas 1. Biofuel Production 2. Production of Alternative Fuels 3. Petrochemicals Production 4. Fertilizers 5. Industrial Units Design 6. Engineering, Control and Process Optimization 7. Environmental Engineering 8. Waste Recovery and Raw Materials 9. Management and Technological Innovation 10. Green Chemistry Considering the Social Demand Defining the profile of entering students: 1. Chemical Engineers 2. Bioprocesses Engineers 3. Industrial Chemists 4. Chemists Total students registered = 116 Undergraduate Course: Students Origin ► 66% of the students are between 25 and 35 years ► The average age is 29 years Students Employment Bond Provenance of the students Among the 26 Brazilian states, 15 are represented in the course 5% of the students are foreigners from: Colombia, Ecuador, Peru and Argentina The curricular structure The curricular structure Biofuels - Process The curricular structure Petrochemistry and Fertilizers - Process The curricular structure Biofuels and Petrochemistry - Design Research Subjects Until August 2013 were concluded 31 Master Dissertations Teaching Staff of the PMEBP: 100% DSc 45 permanent professors into the course and 8 collaborator professors 2 PETROBRAS EMBRAPA CETEM 3 1

Download