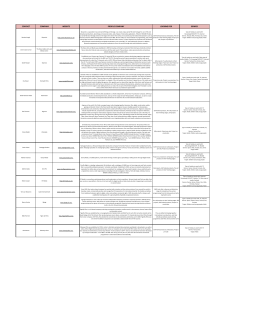

Sociedade Brasileira de Química (SBQ) Polyvinyl butyral (PVB) from laminated-glass waste for printable photonic devices Diana R. S. da Silva (PG)* e Petrus A. Santa-Cruz (PQ) *[email protected] Departamento de Química Fundamental, Universidade Federal de Pernambuco, 50740-540, Recife-PE Keywords: PVB, laminated-glass, thermal evaporation, printable films, Europium nanofilms. Laminated-glasses materials consist of a sandwich comprising a core polymer (PVB in the present case) between glass sheets. It presents greater safety in case of impact, protection against ultraviolet 1 radiation and improvements in acoustic insulation . The objective of this work is the establishment separation processes and characterization of PVB films obtained from this discarded material (usually from laminated glass of car windshields) previously for encapsulating photonics devices produced in our 2 group , and currently to study the feasibility of the printable form of these devices, allying the optical and thermochemical properties of the polymer by spectroscopic and thermal characterization. In order to study the PVB volatility by sublimation and the optical properties besides a molecular photonic film, it was conducted the deposition of a europium complex following by a deposit the polymer both by thermo-evaporation in an AUTO 306 BOC Edwards device, monitored by optical spectra, shown in fig.3. 100 95 Transmittance (%) Introduction 90 85 Eu(btfa)3bipy + PVB 80 PVB Eu(btfa)3bipy 75 70 300 400 500 600 700 800 900 1000 (nm) Results and Discution The PVB film obtained from mechanical separation of windshield automotive glass was analyzed after removal of any dirt by organic solvents chosen by the lower boiling point and toxicity and non-reactivity with the polymer. The PVB characterization was started by TGA and optical spectroscopy. TGA analyzes were performed with masses of 10 mg of PVB shredded in small platinum crucibles, heated to 600 °C at a rate of 10 °C/min, resulting in the weight loss according fig. 1, for recycled and commercial forms. 1,1 Reciclado Comercial 1,0 0,9 Normalized Mass 0,8 Figure 3: UV-Vis-IR spectra of films deposited by thermal-evaporation. Conclusions To start the separation process of the PVB from the vitreous waste as starting material, the best solvent identified was ethanol, among all solvents tested. Preliminary results were analyzed to establish the process using PVB as the basis of printable molecular devices dispersed in the polymer as nanocomposites with molecular active parts. The first results of sublimation were obtained in AUTO 306 equipment by vacuum controlled thermal evaporation, resulting in a good assembly of polymer and molecular complex film. 0,7 0,6 0,5 a) 0,4 0,3 b) Congratulations 0,2 0,1 0,0 100 200 300 400 500 600 700 800 Temperature (°C) Figure 1. a) TGA and b) UV-Vis-IR transmission spectra of recycled and commercial PVB. Transmittance in UV-Vis-IR range resulted in very satisfactory transparent films in visible-IR region which let pass the light and block selectively UV in both PVB samples, as shown in figure 2. 36a Reunião Anual da Sociedade Brasileira de Química __________________________________________ 1 Cho, C. H.; Cho, M. S.; Sung, J. H,; Chol, H. J.; Jhon, M. S. J. Mat. Science, 39(9): 3151-3153, 2004. 2 G.F. de Sá, O.L. Malta, C. Donegá, A. M. Simas, R. L. Longo, P. Santa Cruz, E.F. Silva Jr., (Coordination Chemical Review,196, 2000, 165.

Download