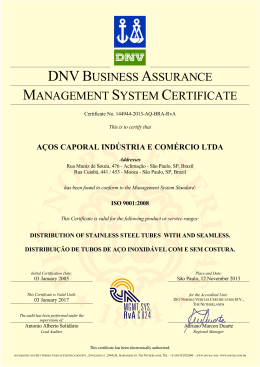

Special Foundation Services Since 1975 C850-FD60 Hydromill Table of Contents Company 2 Team 4 Equipment 5 Services Large-diameter bored piles and Diaphragm piles Monitored CFA piles CFA piles for contaminated soils Slurry walls with electronic monitoring Tiebacks Static load tests Root piles 6 6 8 9 11 12 13 13 Ecology and Environment 14 Main customers 15 Main industrial projects 16 Brasfix 17 Company Geofix Engenharia, Fundações e Estaqueamento S/C Ltda was founded in 1975 and has been involved in major engineering projects throughout Brazil and abroad for more than three decades. Programs in deployment and implementation deal with the following issues: It began its activities working with Franki piles and today is known for the main specializations of foundation engineering, being a pioneer in electronic monitoring of foundations. • Systematization of information and data; Its modern equipment coupled with a specialized technical staff make it highly qualified to meet the challenges of foundation and geotechnical engineering tasks, ensuring its customers excellent services, speed, savings, and quality in the building projects executed. • Development and Adaptations with a focus on the integration of networks; • Sustainability of the Company and it Productivity; • Training to develop the potential of our Human Resources; Maintenance shop • Implementation of the Quality Management System according to ISO 9001 standards integrating it with two other systems: Management of Environment and Health & Safety. Our Values: Trust Agility Our Mission: Geofix ≡ Quality Integrated Policy of Quality, Safety, and Environment Customer service goals: • Convey confidence and safety in the services provided. • Employ technology for customer satisfaction and meeting their requirements. Continuous Quality Improvement Programs Customer service goals: • Convey confidence and safety in the services provided; • Encourage and prioritize development in human resources. Geofix invests in a series of Programs for Continuously Improving the Quality of its services. • Employ technology for customer satisfaction and meeting their requirements. Company goals: Geofix established new policies and values, which means that its processes in all sectors and services it works with are according to ISO 9001 and are being incorporated in a systemic and planned way. Employee goals: • Be efficient. • Continually improve performance. Environment goals: • Comply with legal requirements. • Prevent and minimize generation of liquid effluents and gaseous emissions. To do so, we depend on two interdepartmental teams: Integration and Coordination, along with active participation of the Board and Quality to give continuity to the procedures. Safety and health goals: • Comply with legal requirements. • Prevent occupational health hazards (injuries or diseases). The Continuous Improvement that we pursue has a focus on People, Processes, as well as the Executive and Administrative Procedures. Each focus includes programs that are consistent and harmonized among themselves in order to meet the needs of our customers. Faria Lima / SP | 13,015 m² with 50 cm slurry wall 2 GEOFIX FUNDAÇÕES Warehouse and maintenance shop 3 Team Geofix’s administrative and technical teams ensure customer service quality while monitoring all the stages of a building project’s executive process. Equipment Geofix equipment is modern with an average age of 5 to 6 years. They undergo preventive maintenance and are often retrofitted. B250 Hydraulic drill In search of new technologies, Geofix has acquired a Hydromill machine, which makes it possible to carry out building projects requiring diaphragm walls in rocky soil with greater agility and precision. They are professionals with an entrepreneurial profile and deep technical knowledge, attentive to meeting deadlines and quality of services. B300 Hydraulic drill FD 60 Hydromill machine Because of Geofix’s concern with environment quality and management, it is planning on replacing its diaphragm wall and barrette pile equipment for hydraulic equipment because they have a lower noise level, are safer in the verticality of the excavation, ensure execution in high-resistance soil and monitored control of execution, along with Pollutant Emission Control. 4 B300 Hydraulic drill executing Continuous Flight Auger (CFA) B300 Hydraulic drill QUY-80B Crane Services Foundation technology and geotechnical engineering are the specializations that Geofix stands out in both the construction market as well as for infrastructure services such as subways, airports, highways, hydroelectric plants and railroads. Among the types of services highlighted are projects for environmental control such as Recovery of degraded soils, Contaminated groundwater containment, Construction of filters and capturing material, and Containment of pollutants. Large-diameter bored piles and Diaphragm piles Bored piles or diaphragm piles are executed in a circular or rectangular manner molded in place and implemented with submerged concrete. Though relatively recent (developed in the late 60s), the process impacted excavation and foundation techniques. Its success is due to several factors: the multiplicity of its applications, the development of excavation equipment and mud processing centers, and availability of bentonite for industrial use. Bored and diaphragm piles are highly resistant and of low deformability, which puts them as the most suitable solution to support of excavations close to existing buildings. Work Administration Center - MG | 8,800 m³ of Diaphragm piles Advantages and applications Foundation elements, transmitting loads to deeper layers; • Execution without vibration and noise inherent to pile driving foundations or propping; • Possibility of passing through layers of high resistance; • Streamlines execution. 120,000 ml of continuous flight augers Ø 30cm to Ø 60cm, and 41,394 m³ of bored piles Ø 120cm, Ø 140 cm, and Ø 160 cm 6 GEOFIX C850 Hydraulic drill - Casagrande 7 Monitored CFA piles A Continuous Flight Auger (CFA) is a pile of concrete cast in place, carried out by introducing into the ground through rotation an auger with a central pipe shaft for the injection of pumped concrete through the auger pipe while it is withdrawn without rotation. In our country Geofix Fundações Ltda. began to use the Continuous Flight Auger in 1995 and currently has various models of equipment, which provide a safe and adequate execution for several types of soils and various depths, ensuring the company’s leadership position in the Foundations Engineering market for this kind of pile. Highlights • Geofix is a pioneer in the implementation of Continuous Flight Augers and in electronic foundation monitoring; • Builds Flight Auger Piles with up to 1.20 m in diameter and 34 m deep; • Has made more than 5 million meters in length of CFAs of Ø 0.25 m to Ø 1.20 m. Aerial view of the Tubarão Port site - Vale - Vitória/ES Construction site of multiple warehouses in CFA piles CFA piles for contaminated soils The Continuous Flight Auger for contaminated soils, known as Flight Auger with Displacement is a cast pile in place and the drilling shaft has a special auger on its extremities that does not allow the removal of earth. It’s basically a kind of pile that compresses the soil laterally keeping it from being displaced vertically, which requires equipment with a high torque. Due to the fact that it does not displace the soil, this pile is specifically designed for contaminated areas in which the removal of excavated material would bring additional problems for transportation and disposing this material in special landfills. Highlight • The auger pile with displacement does not pollute the environment in contaminated areas because there is no removal of soil. Juiz de Fora/MG Construction Site | 62,880 ml of CFA piles 8 GEOFIX B300 Hydraulic drill with special auger 9 Slurry walls with electronic monitoring Walls cast in the ground, also known as continuous or slurry walls, are curtains made by filling with concrete (plain or reinforced) or another material (plastic mortar) an open trench in the ground and kept stable with the aid of a special mud. Geofix is introducing the electronic monitoring in the implementation process to control the position and verticality of the excavation. Though relatively recent (developed in the late 60s), the process impacted excavation and foundation techniques. The success of this process is due to several factors. The first is the multiplicity of its applications, including: • Water and earth fill elements (rigid diaphragms) in temporary or permanent excavations (roads, stations and underground or partially underground galleries, basements of buildings, pump houses, turbines or reactors, etc.), and building projects such as ports, dams, dikes, and sluices. Besides providing containment, the walls can still receive vertical loads (portable composite walls). • Waterproofing elements (plastic diaphragms), aiming to control water seepage in excavations, dikes, dams, and reservoirs. • Foundation elements (diaphragm piles), transmitting loads to deeper layers. The development of excavation equipment and mud processing centers, along with the availability of bentonite for industrial use also made its success possible. The technique has undergone innovations such as the use of precast panels and, more recently, cables molded into panels in situ, and later, prestressed. It is widely known that walls built underground use techniques under development, requiring much study and research. Detail of tieback anchor wall - Faria Lima / SP Advantages of the process • Execution without the vibration and noise inherent to pile driving foundations or propping; • Possibility of passing through layers of high resistance; • As supporting elements of excavations, these walls are highly resistant and do not deform easily, which makes them the most suitable solution for supporting excavations near existing buildings; • Reduces the lowering of the water table behind bracing (and thus of the foundations of nearby buildings) by placing the lowering installation within the excavation or injecting it into the bottom of the excavation; • Streamlines execution; • Often more economical due to the incorporation of the walls into the permanent structure. C400 Diaphragm - Casagrande and 50 GB - Bauer 10 GEOFIX 11 Tiebacks Static load tests Tiebacks are linear elements capable of transmitting traction strains between their ends. The end that is out of the ground is known as the head end and that which is underground is known as the anchored end and designated by length or anchor bulb. The section that connects the head to the bulb is known as free stretch or free length. Geofix, concerned with the quality control of its flight augers, has already performed approximately 200 static load tests. The head is usually the prop or support for the structure and is generally composed of metal parts with particular details such as nuts, shackles, eyes, or wedges in order to maintain tension. Most often the bulb anchor consists of mortar adhering to the steel and to the ground. Along the free stretch the steel must be free of cement, or in other words there must be no adherence of the mortar to the steel. Therefore, it is usual practice to coat the steel with a material that isolates it from the mortar such as grease, tubes, or plastic hoses, flexible material covering, etc. According to the Brazilian Standard (NBR 5629), a rebar cannot have a free length of less than 3 meters. The intensity of execution of these load tests comply with the quality and knowledge requirements of this foundation element in various soil types in Brazil. Detail of tiebacks installation Execution phases These are the main phases when working with Tiebacks: • Drilling • Installation of the rebar • Injection • Prestressed • Incorporation Performing the static load test Root piles Root piles are characterized mainly by the high friction developed by applying the load and by the versatility of the equipment used, which, being small, can access areas with limited dimensions. Advantages of the process Due to the absence of vibrations and decompression of the land, done by the drilling process, the root pile ensures the integrity of nearby buildings that may be sensitive. • Can be executed in limited spaces; Geofix also develops diaphragm walls for containment of pollutants. • No vibration and decompression of the land; • Used on land with geological profiles containing boulders, rocks, and even concrete. Geofix also develops Slurry walls for containment of pollutants. Executing drilling for tiebacks installation 12 GEOFIX Faria Lima / SP | 13,015 m² with 50 cm slurry wall 13 Main customers Ecology and Environment Geofix has developed executive processes of environmental preservation. RECYCLING FLOCCULATION This process consists of recycling bentonite slurry used in the excavation process carried out by equipment called a “recycler”, which separates the slurry (water + bentonite) from the materials that make up the local soil (sand/ clay), inserted during the excavation process (decanting). After this process, the slurry returns to the storage silos for reuse while the recycling material is discarded in dump trucks in the same way as the material from the excavation of piles/wall. This process reduces the amount of slurry to be used in the building project because significantly increases the reuse of bentonite slurry to be applied. When the bentonite slurry does not reach the minimum levels of tests required by norms, then it should be discarded from the job site. We used “flocculation” equipment in order to eliminate any disposal of slurry to outdoor landfills, which consists in the treatment of slurry inside a special tank, where a flocculent material is added (at a pre-defined dosage), and, using a pump, the sedimentation process is turned on, which is the separation of the components of this slurry. The soil with bentonite stays at the base of the tank in a solid state (about 15% in volume), and the water stays on the surface in a liquid state (about 85% in volume). After the end of the process, the solid material is discarded along with the material from the excavation of piles/wall and the water returns to a storage silo and can be reused for other purposes (washing of tires, roads, etc.). Detail of the Slurry Center with recycler and flocculator ABACO AGM AHF ALBAMAR ALBRÁS ALIMONT ALMEIDA SAPATA AM AMIRA AMY ANDRADE GUTIERREZ ANDRADE VALLADARES ANTÔNIO E HELENA ZERRENER ARTCON ASSOCIAÇÃO DE ESCOLA SUPERIOR DE PROPAGANDA E MARKETING ATC ATLÂNTICA BALTEC BARBARA BARBOSA BARRO BARRIL BASIC BASILE BAUTEC BECO CASTELO BECORP BETANCOURT BETER BKO RASILART BRASKEM BRAZIL REALITY BURTI CAMARGO CORRÊA CANAL CAPARAÓ CAPITÂNIA CARMO CARNEIRO E MATOS CÁUCASO CBPO CEBRACE CEMEK CESBE CG CGN CHARLES CAMBOUR CHEMIN CIA DE TECIDOS NORTE DE MINAS CIA ZAFFARI CIMENTO POTY DA PARAÍBA CMC CODESHOP COGELTA COLLEM MOHALEM COMPANY COMPART CONCEITO CONCIVIL CONCREJATO CONCRETA CONCRETO CONGELTA CONMAR CON-SERV CONSID CONSTRAC CONSTRAN CONSTRUBASE CONSTRUSOLOS CONVEX COSIL COSTA LESTE CR. ALMEIDA CULTURA INGLESA CURY CYRELA DALLA LISBOA DARPAN D’AVÓ DE PAULA DEPLAN DI FIORI DIÁLOGO DITOLVO DOFRAN DOLPHO LINDENBERG DOM CABRAL DOMINUS DP DUMEZ - GTM EDIVIA EGELTE ELEPLAN ELEVATION ELIVEL EMBRAED EMOBREL EMPARSANCO EMPLATEC EMR ENAR ENGEFORM ENGESIQUE ENGINEERING ENIX ENTERCO ÉPURA ESTACON EVEN EXTO EZ TEC F. REIS FACULDADE ARMANDO ALVARES PENTEADO FACULDADE ZONA LESTE FAIRBANKS & PILNIK FGF FIVE FMU FORD FORTES FRAIHA FRANCHINI FRANCISCO ALVES FUNDEP GALMO GAUTAMA GEOTER GHG GOLDFARB GOLDSZTEIN GONÇALVES DE CARVALHO GONVARRI PARANÁ GRECO PAINCEIRA GS GUTIERREZ HAUER HEIL HM HOCHTIEF HOGA HOSPITAL ANCHIETA HOSPITAL BANDEIRANTES HOSPITAL PORTUGUES HOSPITAL SANTA JOANA HUDSON IGREJA UNIVERSAL DO REINO DE DEUS INPAR INTEGRAL IORESI FERNANDES IRMÃOS MAUAD IRMÃOS THÁ ITAMINAS IVO RIZZO JACUTINGA JAIME ALEIXO JARDIM JCR JEREISSATI JORGE BALLAN JORGE BERETTA JOSÉ CARLOS ZACHARIAS JOSIL KAJIWARA KAUFFMANN KLABIN SEGALL KOBRASOL KRUT L. ANUNZIATTA L.M. LABAT LAGUNA LANZA RICALDONE LÍDER LITTIG LIX DA CUNHA LORENGE LOSANGO LOTUS LUCIANO WERTHEIM LUCIO M. DONADELLI M.BIGUCCI MAC MAFRA MAGNESITA MAGNO MARTINS MARCO MARQUES MARTINS CAMPOS MASA MASCARENHAS BARBOSA ROSCOE MASTER MATEC MAURÍCIO CUKIERCORN MAYER MAZZINI GOMES MEGA MENDES JUNIOR MERIDIANA MESQUITA E RODRIGUES MÉTODO METRON MGR MHA MILLENIUM MINAS TENIS CLUB MIRO MITTO MOGI MOISÉS MIROCZNIK MONTOSA MORO MPC MSB/SANCHES MULTIPLA MULTIPLAN MUNHOZ MUNTE MZM NAMOUR NERPLAN NORBERTO ODEBRECHT NOVOMARCO OAS OBRACIL ONODA ORTENG SPE PAES & GREGORI PANAMERICANA PARANASA PATRIMAR PAULA EDUARDO PAULINO PATRUS PAULISTA PAULITEC PAULO OCTÁVIO PBR PEDRO BRONDI PENTAGONAL PEPPE PEREIRA PETER PILAR PILKINGTON PINHEIRO PJ PLANAR PLANEL PMK PORTE POZZANI PRATES PRIME PRISMA PROCASA PROCAVE FG PRODUSHOPPING PROENG PROFOR PROMORAR PUC PUR PWR QUALIMAT QUEIROZ GALVÃO RACIONAL RD RDO READY REFRIO RENAULT RESULT RFM RIBEIRO CARAM RICCI RIO ROFFER ROSADA ROSSI RP RRG SADE VIGESA SAINT - GOBAIN - CEBRACE SALDANHA SAMARA SAMPAIO BACOS SANTA LUIZA SANTA MONICA SÃO FERNANDO SÃO JOSÉ SCC SCHAHIN SEGURATEC SEÍSA MESTER SENGEL SERGUS SERPAL SESC SHIMIZU SHOPPING TACARUNA SHPAISMAN SIMEIRA SINCO SISTEMA SITAL SOCIEDADE ITACOLOMI SMS DEMAG SOECON SOMA SOUEN NAHAS SQG STC TATI TECCO TECH TECNUM & CORPORATE TEIXEIRA TEIXEIRA MARTINS TENDA TEREPINS E KALILI TESSLER TIBÉRIO TOLEDO FERRARI TOTAL TPA TRAMONTINA FARROUPILHA TRANSCOSUL TREND’S TRIKEM TRISUL TS TURNER UNI UNIMOV UNIP UTC V2 VASCONCELOS VENDECASA VÉRTICE VESPER VIERO VILLARES VIVENDA NOBRE VOTORANTIM YUNY YVES MIFANO ZABO ZAPPI ZKF ZOGAIB ZORTÉA 15 Main industrial projects Steel Industries and Plants ALUNORTE - Barcarena / PA PROJETO VEGA DO SUL - São Francisco do Sul / SC GALVASUD GALVANIZAÇÃO (CSN) - Porto Real / RS GONVARRI - Capela Velha - Araucária / PR GONVARRI - Rod. do Xisto, PR 476/5005 - Araucária / PR GONVARRI - Zona Rural - Hortolândia / PR CIA VALE DO RIO DOCE (CVRD) - São Luís / MA CIA VALE DO RIO DOCE (CVRD) - Vitória / ES TERMINAL TRS DE ALIMENTAÇÃO DA VALE (CVRD) - Vitória / ES MAGNESITA - Fábrica de Monolíticos - Contagem / MG CENIBRA - DESCASCAMENTO DE LINHA 2 - Paulínia / SP LAMINADOR DE TIRAS E QUENTE (CST) - Vitória / ES FÁBRICA DE GALVANIZADOS - Nova Lima / MG CST - Companhia Siderúrgica Tubarão - VITÓRIA / ES BRASMETAL - Diadema / SP USIPARA - BARCARENA / PA GERDAU Araçariguama PLANAR - Alunorte (3 tanques e 1 clariador) PARÁ PIGMENTOS Metallurgy companies THERA - São José dos Pinhais / PR SOLECTRON DO BRASIL - São José dos Campos / SP TRAMONTINA - Farroupilha / RS VILLARES - Caçapava - Pindamonhagaba / SP Mining CESBE - MINERAÇÃO MARACÁ - GOIÂNIA Pulp & Paper VOTORANTIM PAPEL E CELULOSE - Jacareí / SP ARACRUZ PAPEL E CELULOSE - Vitória / SP VOTORANTIM PAPEL E CELULOSE - Salto de Pirapora / SP CIA SUZANO DE PAPEL E CELULOSE - Suzano / SP KVAERNER / BAHIA SUL - Mucuri / BA Automotive FORD DO BRASIL - Fábrica Ford Amazon - Camaçari / BA RENAULT DO BRASIL - Fábrica Ayrton Senna - São José dos Pinhais / PR VOLKSWAGEN - São Bernardo do Campo / SP GENERAL MOTORS DO BRASIL - Gravataí / RS PARKER - São José dos Campos / SP Cement CIMPOR - Campo Formoso / BA CIMENTO DAVI - Santa Luzia / MG FÁBRICA DE CIMENTO HOLDERCIM - Cantagalo / RJ CIMENTO POTY DA PARAÍBA - Caaporã / PB Chemical CARGILL - São Paulo / SP MAYER DO BRASIL - São Bernardo do Campo / SP Textile CIA DE TECIDOS NORTE DE MINAS (COTEMINAS) - Montes Claros / MG MANCHESTER - Betim / MG MECÂNICA E ESTAMP. SÃO BERNARDO DO CAMPO - Itaquaquecetuba / SP Mechanical B. GROB - São Bernardo do Campo / SP FÁBRICA MEIWA - Arujá / SP CENIBRA - BELO ORIENTE / MG SULZER - JUNDIAÍ / SP Public Projects CANALIZAÇÃO DO RIO CABUÇU DE CIMA - Guarulhos / SP ESTÁDIO OLÍMPICO (1ª FASE) - Rio de Janeiro / RJ ESTÁDIO OLÍMPICO (2ª FASE) - Rio de Janeiro / RJ METRÔ DE BRASÍLIA - Brasília / DF CIDADE DO SAMBA - Rio de Janeiro / RJ PISCINÃO ARICANDUVA - São Paulo / SP CORREDOR VIÁRIO AYRTON SENNA - São Paulo / SP COMPLEXO MACKENZIE - São Paulo / SP EMURB - TÚNEL SOB A AV. SANTO AMARO - São Paulo / SP PASSAGEM TOM JOBIM - São Paulo / SP CALHA DO RIO TIETÊ - LOTE 04 - São Paulo / SP REURBANIZAÇÃO DO VALE DO ANHANGABAÚ - São Paulo / SP CÓRREGO DOS MENINOS - São Caetano do Sul / SP PASSAGEM FARIA LIMA - Trecho Eusébio Matoso - Rebouças - São Paulo / SP CONSTRUTORA BETER S/A - METRO BH SOEICON - TERMINAL HERMELINO MATARAZZO 16 GEOFIX Warehouses and Storage Silos ARMAZÉM GRANELEIRO BUNGE - Vitória / ES BASES DE TANQUES - Rod. SP-332, Km 121 - Paulínia / SP SILOS LAFARGE - Matozinhos / MG ARMAZÉM GRANELEIRO 09 - CVRD - Vitória Data Management RECALL DO BRASIL - Jundiaí / SP Airports AEROPORTO SALGADO FILHO - Porto Alegre / RS AEROPORTO DE MACAÉ - Hangar - Macaé / RJ AEROPORTO DE MACEIÓ - Maceió / AL AEROPORTO REG. DA ZONA DA MATA - Rio Novo / MG Post offices ECT - SANTO AMARO - São Paulo / SP ECT - SAÚDE - São Paulo / SP ECT - PORTO ALEGRE - Porto Alegre / RS Refineries PETROBRÁS UPGN - Pilar / AL REFINARIA DE PETRÓLEO MANGUINHOS - Rio de janeiro / RJ PETROBRÁS - Linhares / ES Radio and TV TV GLOBO - São Paulo / SP TV CULTURA - TORRE DE TRANSMISSÃO - Sumaré - São Paulo / SP Clubs MINAS TÊNIS CLUBE - MG Telephony TIM DATACENTER - Santo André / SP Schools EPAC - Sto André / SP ESPM - PRÉDIO SEDE - VILA MARIANA / SP UNIBAN - Campo Limpo / SP Food SADIA S/A - Minas Gerais Supermarkets WAL-MART - Contagem / MG WAL-MART - Tamboré / SP HIPERMERCADO EXTRA - São Bernardo do Campo / SP D’ÁVO SUPERMERCADOS - Suzano / SP PÃO DE AÇÚCAR - TREMEMBÉ / SP SUPERMERCADO BARONESA - Mauá / SP Malls SHOPPING TACARUNA - Recife / PE SHOPPING VILLAGIO PAMPULHA - Belo Horizonte / MG SHOPPING HIGIENÓPOLIS - São Paulo / SP SHOPPING CURITIBA - Curitiba / PR EXTENSÃO DO SHOPPING ALDEÓTA - Fortaleza / CE SHOPPING BEIRA MAR - GUARAPARI / ES SHOPPING CENTRO SANTA MÔNICA - FLORIANÓPOLIS / SC AMPLIAÇÃO DO SHOPPING CENTER UBERLÂNDIA - Uberlândia / MG Hospitals HOSPITAL ANCHIETA - Brasília / DF HOSPITAL SANTA JOANA - São Paulo / SP HOSPITAL SÃO CAMILO - São Paulo / SP HOSPITAL SÃO LUIZ - São Paulo / SP Brasfix Geofix is affiliated to Brasfix, a company founded in August 2000 with the purpose to offer to their customers state-of-the-art technology with the latest equipment and specialized labor force for building foundations for sea and river port projects. GNL Flexible Terminal - RJ Brasfix relies on the support of Geofix in equipment and skilled professionals to perform its services with excellence. Services performed by Brasfix: • Large diameter excavated offshore piles for bridges, ports, and piers. Urucu-Manaus Gas Duct Installation - AM • Concrete or metal pile driving with hydraulic or vibratory hammer. • Submerse pile driving for oil platform jackets. • Sheet pile driving. • Large diameter Horizontal Directional Drilling (HDD). Water Barriers for Containment/Contamination TRIKEM - ORGANIZAÇÃO ODEBRECHT - Maceió / AL BRASKEM - CAMAÇARI / BA (Unidade Cloro-Soda) GLOBAL - Baruito / MT Waste Treatment Facility ETE ITAIPU - Niterói / RJ ETE - Praia Grande / SP ETE - Jacareí / SP www.brasfixfundacoes.com.br Natural gas exploration platform - BA Port Projects WILSON SONS - Santos / SP Bridges PONTE ESTAIADA - Av. Roberto Marinho - São Paulo / SP Glass PILKINGTON / CEBRACE CRISTAL PLANO - Barra Velha / SC CEBRACE CRISTAL PLANO - Jacareí / SP Tires PIRELLI - Gravataí / RS Print Shops EDITORA GRÁFICOS BURTI - Parque Gráfico - São Paulo / SP Bridge over Rio Orinoco - Venezuela São Paulo Av. Luiz Rink, 680 - Vila São José 06286-000 - Osasco / SP - Brazil Phone / Fax: +55 11 2148-9300 E-mail: [email protected] Minas Gerais Rua Tomé de Souza, 860 / Sala 1502 Belo Horizonte / MG - Brazil Phone / Fax: +55 31 3262-0247 E-mail: [email protected]

Download